No matching posts found

Sort By Industry

Thermal Spray Repair – Hydro Thrust Collar

Thermal spray repair of a hydro thrust collar weighing 20 tons. Required machining and restoration to OEM specifications.

Thermal Spray Repair – Hydro Thrust Collar Learn More »

Precision Machining – Trunnion Yoke & Hubs

This was a rush repair of a trunnion yoke and two hubs for a dam gate assembly. Machining completed in 3 days and met OEM specifications.

Precision Machining – Trunnion Yoke & Hubs Learn More »

High-Precision Machining – Pump Casing

This pump casing repair involved high-precision machining, boring blind holes, complex pre-machining setups and custom tooling.

High-Precision Machining – Pump Casing Learn More »

Hydro Turbine Refurbishing – Pressure Relief Valves

Refurbished a 100-year-old hydro turbine relief valve assembly, including manufacturing upper valve bodies, bronze cylinder & shafts, bushings, and rings for a hydro power plant generating 3.2 MW electricity..

Hydro Turbine Refurbishing – Pressure Relief Valves Learn More »

Hydro Turbine Refurbishing – Pressure Relief Valves Learn More »

Engineered Fabrication – New Lime Kiln Trunnion

Engineered fabrication of new lime kiln trunnion, including new roller body and shafts, and thrust roller for a manufacturer of tissue and paper board products.

Engineered Fabrication – New Lime Kiln Trunnion Learn More »

Engineered Fabrication – New Lime Kiln Trunnion Learn More »

Engineered Refurbishing – Hydro Servo Parts

Engineered refurbishing of these hydro servo parts, including the servo piston, piston rod, and turbine shaft for a hydro power plant. All machining, inspections, custom manufacturing, assembly & disassembly, and TIG welding were completed according to OEM specifications.

Engineered Refurbishing – Hydro Servo Parts Learn More »

shaft & hub refurbishing – ship propulsion system

Complete refurbishment of a federal ship’s propulsion system shafts and hubs. All machining, disassembly & assembly, and manufacturing met ABS and OEM approvals.

shaft & hub refurbishing – ship propulsion system Learn More »

shaft & hub refurbishing – ship propulsion system Learn More »

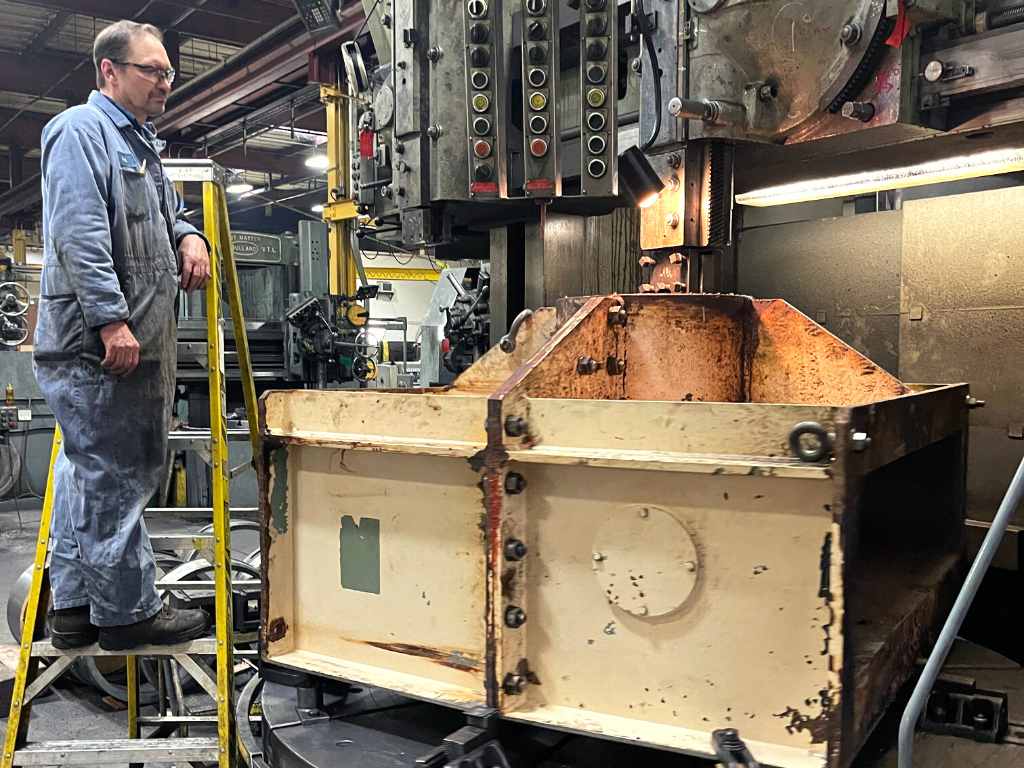

Reverse Engineering & Manufacturing – Rolling Mill Housing

Reverse engineered and manufactured a new rolling mill housing to replace the existing part that sustained catastrophic damage. Our team generated the manufacturing prints, verifying all critical fits and dimensions, and machined the part to meet all technical requirements.

Reverse Engineering & Manufacturing – Rolling Mill Housing Learn More »

Reverse Engineering & Manufacturing – Rolling Mill Housing Learn More »

Repair and Rebuild – Reel Drum

Engineered repair of a reel drum for a paper packaging manufacturer. Work included reshell, journal repair, and complete rebuild within outage schedule.

Repair and Rebuild – Reel Drum Learn More »

Engineered Repair – Recycling Equipment

Engineered repair of friction washer for a plastic recycling plant in the PNW. This project included machining, shaft manufacturing, and balancing.

Engineered Repair – Recycling Equipment Learn More »

Precision Machining – Pintle & Bushings

The pintle and bushings were damaged beyond repair and needed replacement. Our team precision machined the new parts to meet all technical specifications, including critical diameters, TIR, and surface finish.

Precision Machining – Pintle & Bushings Learn More »

Engineered Repair – Ship Winch Drum

This winch system has sustained severe surface damage and is no longer operating efficiently. With precision machining, our team restored the worn out surface and dimensions.

Engineered Repair – Ship Winch Drum Learn More »

Hydro Shaft Refurbishing – Turbine Runner Shaft

Refurbished a 203″ long Kaplan turbine runner shaft for a hydropower plant in the PNW. Work involved stringent requirements from start to finish, additional machining, and custom tooling.

Hydro Shaft Refurbishing – Turbine Runner Shaft Learn More »

Hydro Shaft Refurbishing – Turbine Runner Shaft Learn More »

Journal Repair – Embossing Roll

Engineered repair solution for a damaged journal and worn-out bearing fit in an embossing roll. Our team manufactured a new journal and thermal spray repaired the drive side.

Journal Repair – Embossing Roll Learn More »

Engineered Repair – Screw Press Housing

This screw press housing required emergency repair. Multiple components were severely damaged, and all repairs had to be completed within the mill’s assembly schedule.

Engineered Repair – Screw Press Housing Learn More »

Precision Machining – Blind Flange for Hydro Component

Precision machined an 87″ diameter blind flange for a hydro power plant in Douglas County, Oregon. Critical seal required to ensure safety of repair crew.

Precision Machining – Blind Flange for Hydro Component Learn More »

Precision Machining – Blind Flange for Hydro Component Learn More »

Precision Machining – Ship Stabilizer Components

Large cruise ship needed emergency repair of its stabilizer assembly. A total of 10 components were precision machined, meeting all technical specifications and critical timeline.

Precision Machining – Ship Stabilizer Components Learn More »

Precision Machining – Ship Stabilizer Components Learn More »

Engineered Repair – Plug Screw Feeder

Provided an engineered repair solution to damaged screw feeder equipment critical to paper packaging manufacturing. Read about our process in meeting all technical requirements and rush schedule.

Engineered Repair – Plug Screw Feeder Learn More »

Precision Machining – Propeller blade

Our team precision machined the propeller blade for a container ship transporting critical supplies to Alaska. We met all technical specifications and delivered the part within the drydock schedule.

Precision Machining – Propeller blade Learn More »

Equipment Modification – Feed cylinder

Precision machined this cylinder equipment to meet OEM specifications. Accuracy of machining and conformance to technical specifications and timeline were critical to the equipment modification.

Equipment Modification – Feed cylinder Learn More »

Thermal Spray Repair – Wicket Gates

Thermal spray repair of large wicket gates for a hydroelectric power plant. Wicket gate stem fits were restored back to OEM specifications and saved on long-term maintenance cost.

Thermal Spray Repair – Wicket Gates Learn More »

Shaft & Tapered Sleeve Manufacturing

Manufactured a critical shaft and test sleeve for a science research facility serving federal and commercial customers. Certifications and adherence to specified dimensions, surface finishes, and tolerances were required.

Shaft & Tapered Sleeve Manufacturing Learn More »

New Press Roll – Design & Manufacture

Manufactured and designed new roll and new shafts for upgraded performance.. No OEM drawing was available so the team reverse engineered the new roll and journals.

New Press Roll – Design & Manufacture Learn More »

Thermal Spray Repair – Screw Press

Thermal spray repair on a large industrial screw press with multiple bearing and seal fits that were out of OEM specifications.

Thermal Spray Repair – Screw Press Learn More »

Wind Turbine Main Shaft & Components Repair

The main bearing failed catastrophically and damaged several components including the bearing housing cover, retaining nut, and sealing rings. The bearing housing itself was also damaged and new replacement was not available. With a critical timeline, our team completed all repairs and replacements within the required 10 days.

Wind Turbine Main Shaft & Components Repair Learn More »

Gas Turbine – Machining & Refurbishing

Precision machining of gas turbine components for a pollution control modification project at an Oregon power plant. The turbine case, combustion wrapper, and compressor discharge case were machined to precise specifications and completed within the shutdown timeline.

Gas Turbine – Machining & Refurbishing Learn More »

Ship Shaft – Comprehensive Shaft Repair

Comprehensive shaft repair for a global ship owner and operator. The propulsion shaft had three liners that were severely worn out and each one had a different interference fit that required precision machining. With stringent specifications and critical timeline, an engineering approach was needed from start to finish.

Ship Shaft – Comprehensive Shaft Repair Learn More »

Forming Roll – Machining & Shaft Manufacturing

Comprehensive engineered repair for a forming roll critical to the manufacturing of a fiber cement product. Western Machine Works provided precision machining, shaft manufacturing and installation, grinding and balancing, non-destructive testing, and custom tooling. The result: customer saved capital dollars and time by refurbishing the roll instead of full replacement.

Forming Roll – Machining & Shaft Manufacturing Learn More »

Roller Shaft – Engineered Repair & Manufacturing

Western Machine Works manufactured a replacement shaft for a plate rolling drive roll based on the engineering team’s interference shaft fit design. The damaged drive roll was bored out to accommodate the new manufactured shaft.

Roller Shaft – Engineered Repair & Manufacturing Learn More »

Roller Shaft – Engineered Repair & Manufacturing Learn More »

Loading Arms – Engineered Repair & Machining

Western Machine Works repaired the breast roll loading arms in 4 days, saving critical time and capital dollars for a global tissue manufacturer.

Loading Arms – Engineered Repair & Machining Learn More »