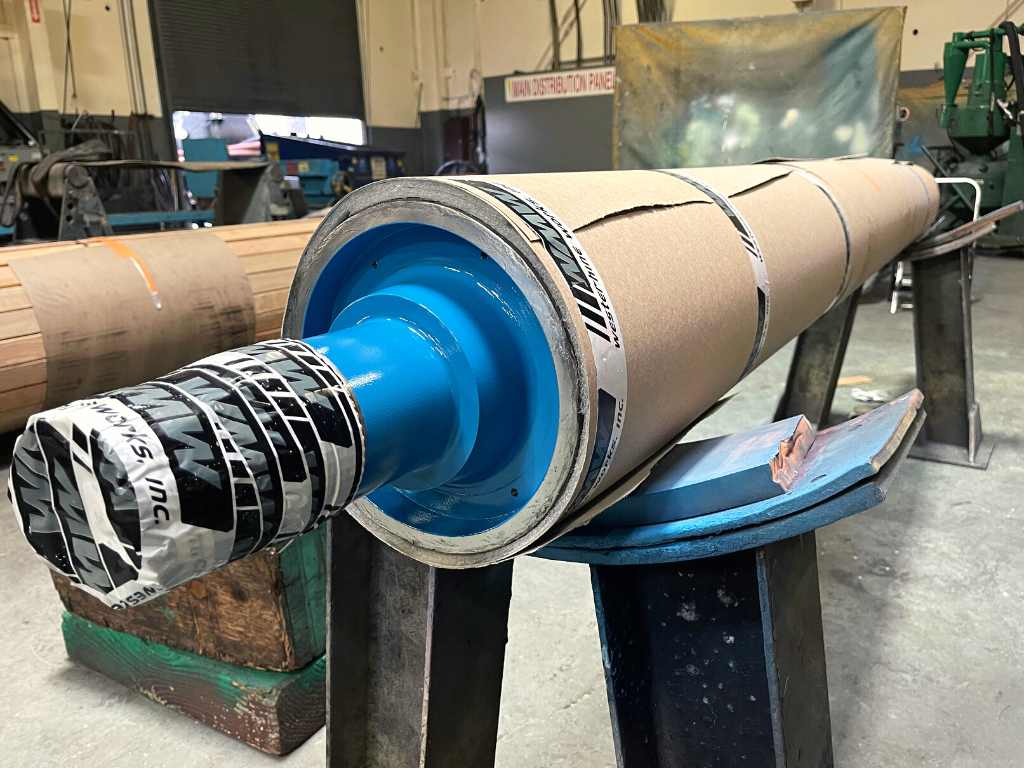

The embossing roll required journal repair due to worn-out bearing fits. The roll was inspected and a crack was revealed on the tending end. Our team proposed a re-journal and manufacturing a carrier ring that would turn concentric to the OD of the roll. The drive end showed no cracks and thermal spray repair was found suitable to return the bearing fit to OEM specifications. See our complete engineered solutions that provided an effective cost-effective solution that meets the customer’s timeline.

Project:

- Part: Embossing Roll

- Details: 142″ overall length, 4140 material (journal)

- Customer: Paper Packaging Manufacturing

Challenges:

- Damaged bearing fits.

- Non-destructive testing revealed a crack in the journal.

- Roll face required careful handling and protection of the proprietary embossing pattern.

Engineered Solutions:

- Non-destructive testing to check for cracks and other damages.

- Set up in the lathe and check dimensions and TIR.

- Machine bearing fit on the drive side in preparation for metallization.

- Sandblast the surface to be metallized and thermally spray with 420 stainless steel coating material.

- Manufacture spacer ring and install against shoulder to restore the drive side to OEM specifications.

- Reverse engineer existing journal and remove from the roll.

- Manufacture carrier ring and bolt on to end of roll.

- Manufacture new journal and install with an interference fit.

- QA and prep for shipment.

- Transportation services for roll pickup and delivery to ensure proper handling and quality compliance.

Results:

- Met all technical requirements

- Delivered repaired embossing roll within the project timeline.