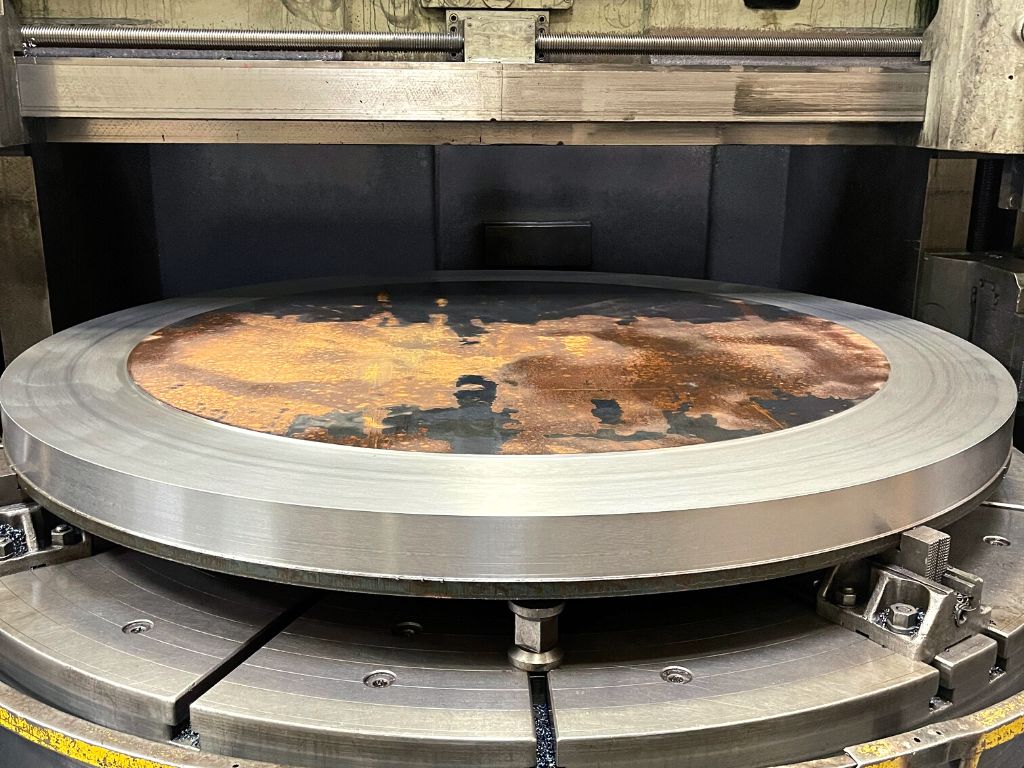

A hydropower plant with a 42MW capacity located in Oregon is undergoing repairs. Built between 1947 and 1956, it went online in 1949 and continues to produce electricity for the Pacific Northwest. Before the repair crew can start work, a new blind flange with 87″ dia. and 44 bolt holes were needed for the turbine shut-off valve. Despite challenges, including a complex pre-machining setup and custom tooling, our team completed the precision machining work ahead of schedule.

Project:

- Part: Blind flange for hydro turbine shut-off valve

- Details: 87″ diameter, 6″ thickness, and 8,000 lbs.

- Customer: Hydro engineering contractor

Challenges:

- Size and weight of material required custom tooling and complex machining setup.

- Critical timeline. The blind flange needed to be completed to meet the outage schedule.

- Precision machining required to ensure perfect seal and safety of repair crew.

Engineered Solutions:

- Procure A-36 carbon steel material

- Machine OD.

- Machine phonographic gasket finish.

- Drill eye bolt on OD of flange for lifting.

- Drill (44) 2-1/4″ diameter mounting holes.

- Deburr holes.

- QC and prep for shipping.

Results:

- Completed machine work within the outage schedule.