Comprehensive Shaft Manufacturing

Western Machine Works provides comprehensive shaft manufacturing with our team overseeing the process from start to finish, ensuring precision and quality of results and customer satisfaction. No matter the complexity or exacting the requirements, Western Machine Works can manufacture custom shafts that meet OEM standards, tight tolerances, and fast turnaround time. With in-house engineering team, experienced machinists, and transportation services, we can provide cost effective and fast shaft manufacturing that can return your critical shaft back in operation within your project timeline.

Shaft Manufacturing Services

We provide a comprehensive shaft manufacturing solution that includes the following services:

- Dimensional inspection.

- Non-destructive testing and failure analysis.

- Shaft design with strength calculations, bending and torsional stress calculations.

- Metallurgical analysis

- Reverse engineering (when OEM prints are not available).

- CNC turning and machining.

- Custom tooling and fixturing.

- Shaft liners or bearing sleeves manufacturing and installation.

- Hydrostatic testing and spark testing if applicable.

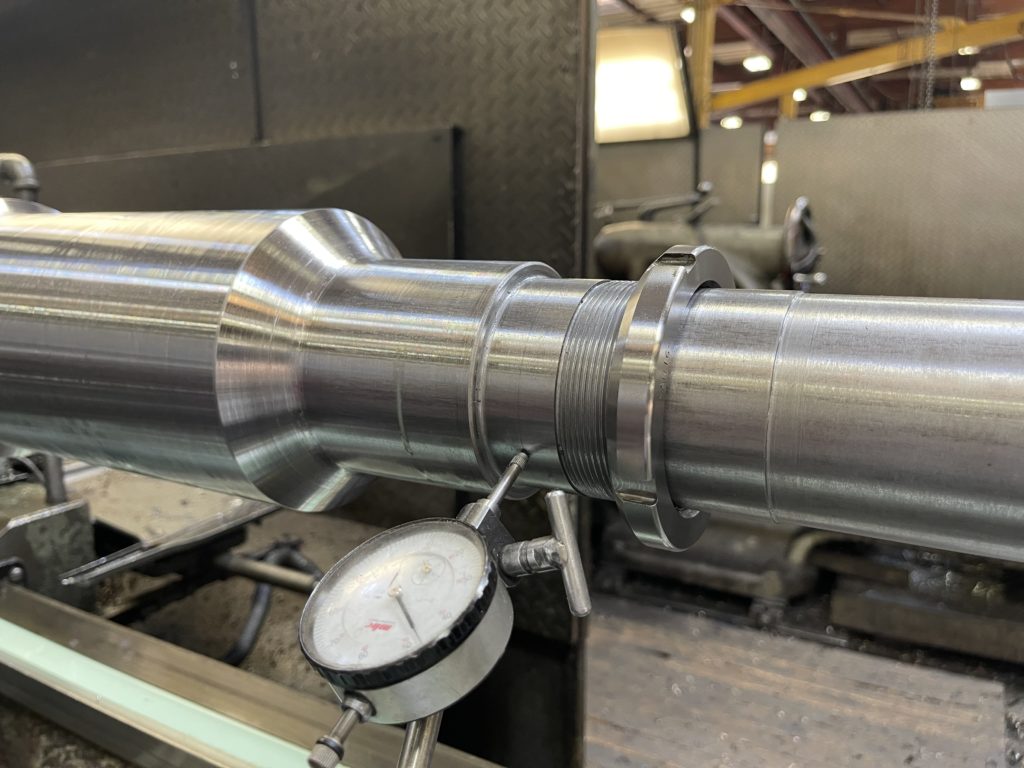

- Dimensional checks and quality control.

- Protective cover installation (as specified).

- Project management.

- Transportation services.

Our engineering team oversees the project from start to finish to ensure precision and reliability in every shaft manufacturing project.

Read about our comprehensive Shaft Manufacturing capabilities for a recent project: Roller Shaft Manufacturing using an interference fit joint design.

(Shafts for steel, marine, pulp & paper, energy, manufacturing, and other heavy industries)

Shaft Manufacturing Process and Quality Standards

The Shaft Manufacturing process starts with understanding the application, operating conditions, cause of failure of previous shafts, and project requirements including third-party approvals and testing. Depending on failure analysis results, the engineering team may suggest a design modification or other components to be manufactured.

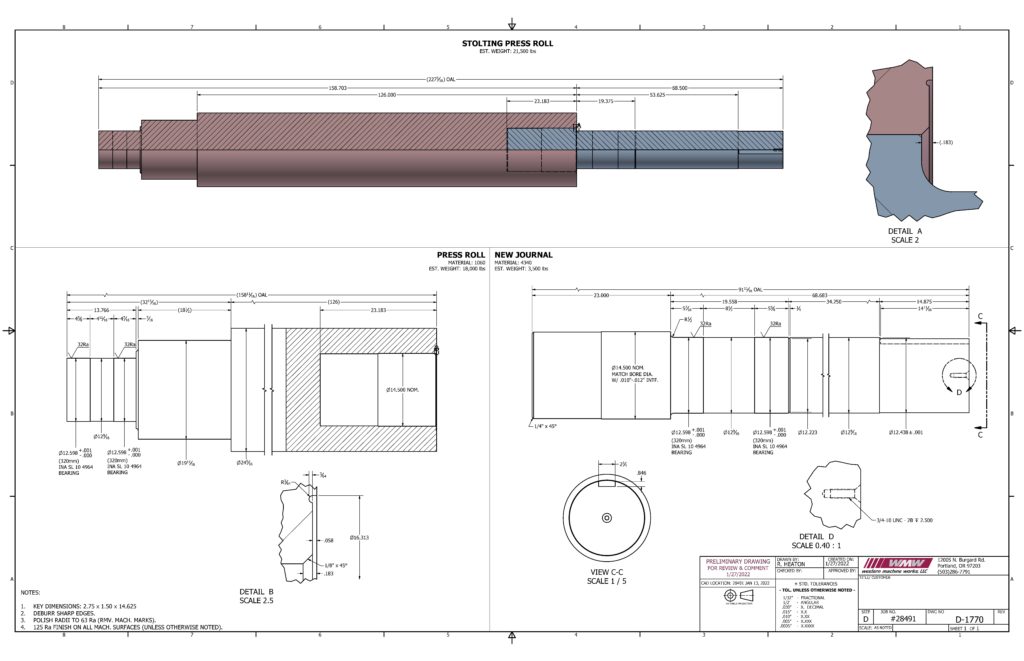

The Engineering team verifies and records the dimensions of the shaft, design and create prints if not available from OEM. Additional strength calculations, bending, and torsional stress calculations are also considered to enhance the performance of the new shaft.

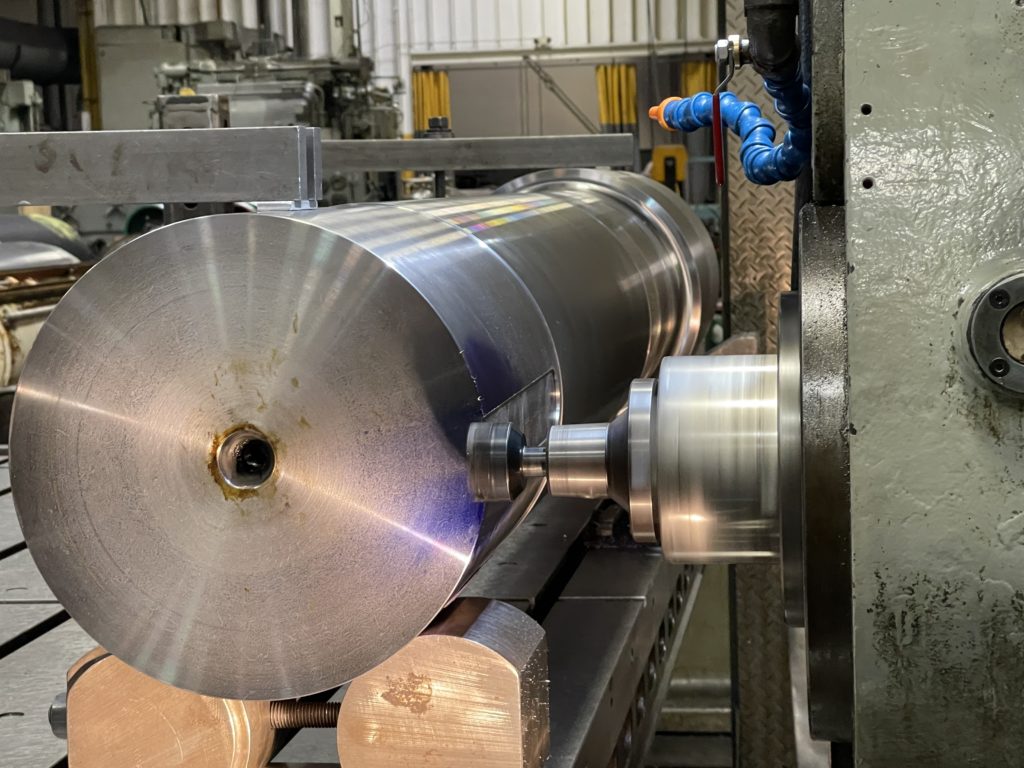

Manufacturing the shaft then involves CNC turning. A bar of solid material like steel is attached to chucks and cut with specialized tools through a subtractive process. Subtractive processes such as cutting and grinding shape the shaft to the proper dimensions and tolerances. Machining processes like boring and drilling create grooves where gears attach to the shaft. Specialized shafts may use different machining processes and require a specific material. Metallurgical analysis can be used to ensure the selected material fits the application.

The material used needs to have a high tensile and endurance strength to withstand static and dynamic loads. If gears are attached to the shaft, the gear is usually made from an extremely durable material, such as carbon steel. These can be further hardened by heat treatment. Depending on the application, some shafts would require additional protective coating such as fiberglass/ epoxy polymer.

Quality manufactured shaft can extend the life and reliability of many critical components used in various industries with demanding operating conditions such as in marine, hydropower, wind, pulp & paper, oil & gas, and manufacturing.

Our shaft manufacturing facility is well equipped with CNC lathe with 78″ centers, engine lathes with 78” swing X 482” centers, vertical boring mill with 103″ vertical, horizontal boring with 60″ x 120″ table capacity.

Most importantly, Western Machine Works has an experienced team of engineers and technicians who can tackle any challenging project. The shaft manufacturing process at Western Machine starts and ends with an engineering-focused approach, valuing quality control with comprehensive initial and final dimensional checks.

More about Shaft Manufacturing

In mechanical terms, a shaft is a rotating component that transfers rotational power from one part to another. Shafts are almost always cylindrical, and often have a toothed wheel or gear that connects to another component to transfer energy to the absorbing component.

Shafts play an intrinsic role in the mechanics of many industries: energy, marine, aerospace, automotive, oil & gas, mining, manufacturing, agriculture, and paper milling.

Engineers can connect shafts and gears of different sizes to create more torque, mechanical energy, and power within equipment.

Shaft manufacturing involves innovative techniques and technology to make the shafts more productive and meet tighter tolerances.

Industry Applications

- Wind Power

- Hydroelectric

- Marine

- Pulp & Paper

- Heavy Equipment

- Industrial Machinery

- Automotive

- Oil & Gas

- Aerospace

- Electronic

- Construction

- Hydraulics

Shafts we Manufacture

- Rotor Shaft

- Armature Shaft

- Ship Shaft

- Drive Shaft

- Hub Shaft

- Fan Shaft

- Repulper Shaft

- Stub Shaft

- Forming Roll Shaft

- Winder Shaft

- Roller Shaft

- Turbine Runner Shaft

Shaft Manufacturing Projects

Rotor Shaft

This 850 HP rotor used for a chemical compressor was failing due to a bearing fit damage to the shaft. Western Machine Works inspected the part and determined that the damage was not repairable. A new shaft was reverse engineered, manufactured, and installed within the customer’s production schedule.

Armature Shaft

Western Machine Works reverse engineered and manufactured a new shaft for a motor armature. The old shaft was severely damaged and repairing it was not a viable option. The armature bore was precision machined to 100% concentricity and the new shaft was installed with the required interference fit.

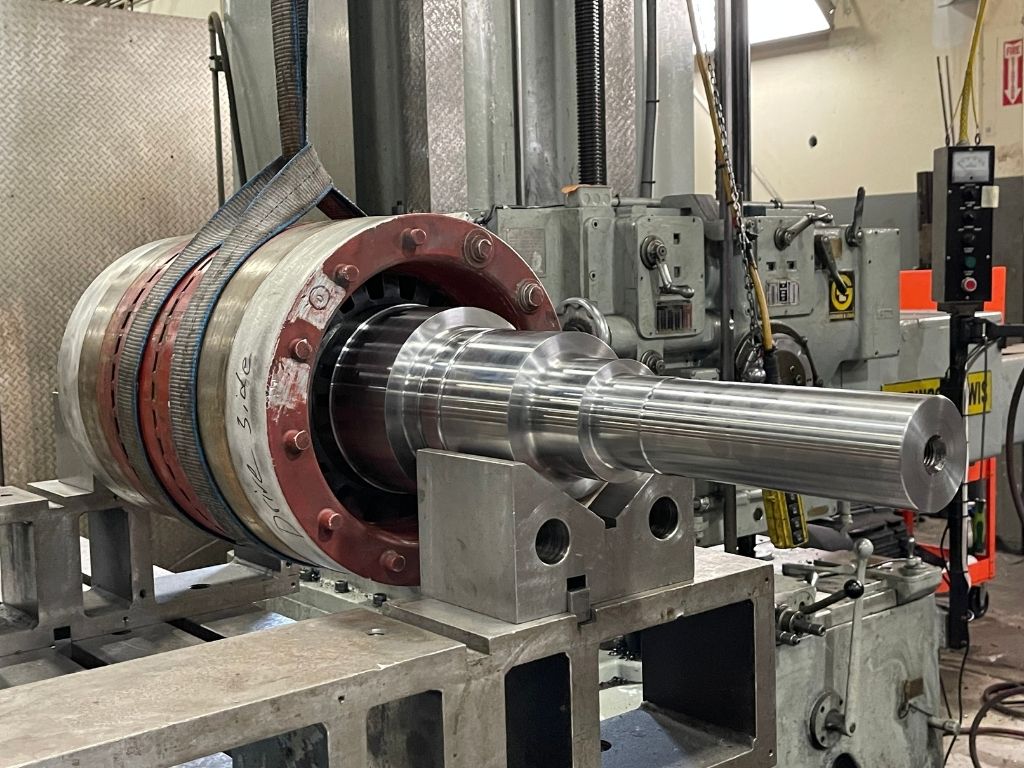

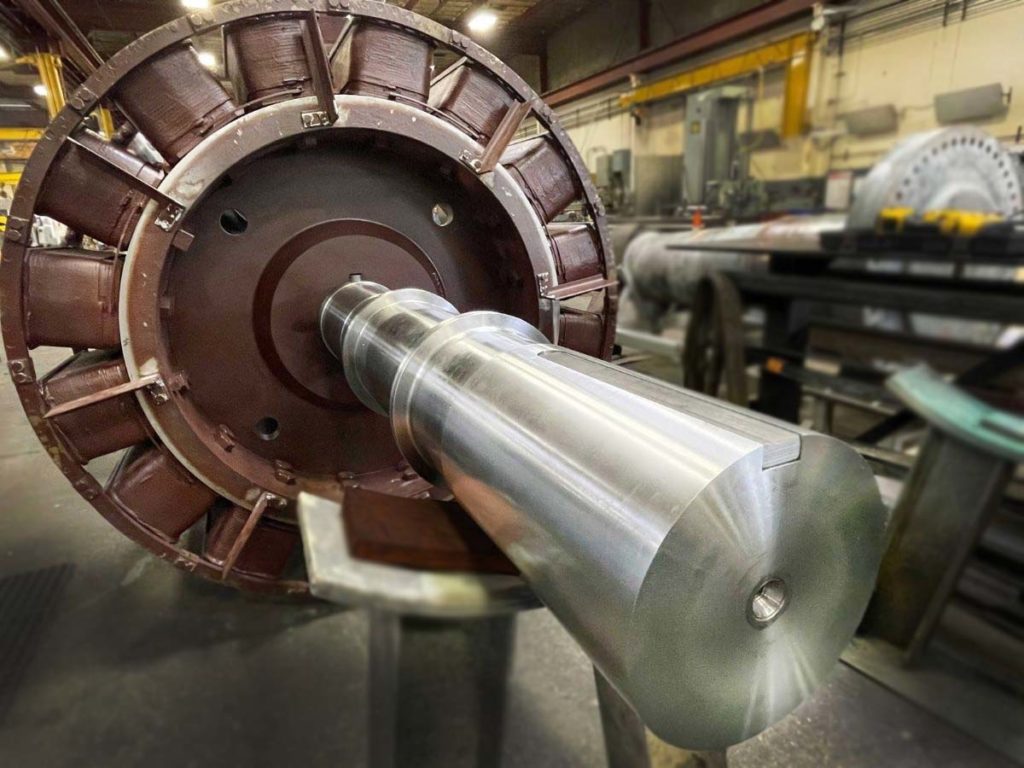

Roller Shaft

The plate roller shaft broke off of a drive roll with the bearing housing and bearings still installed. The engineering team evaluated the loading parameters and operational stress analysis and developed an interference shaft fit design. A new shaft was manufactured using a 4340 steel material.

Western Machine Works provided a comprehensive shaft manufacturing solution for this shaft that broke off with both bearing housing and bearings still installed. Our engineering team proposed an interference joint design and manufactured a new shaft that will be as strong as the original and will be optimized for long-term runnabilty. Manufacturing new shafts with an engineering-focused approach sets our process apart and ensure reliability from start to completion of the project.

Our Experience

Based in Portland Oregon, Western Machine Works has been providing engineered shaft manufacturing and repair to the Western United States and Canada since 1985. Our team can design, modify, create manufacturing prints, and manufacture shafts with or without OEM specifications. We offer a full array of engineering services to ensure every shaft manufactured meets operating parameters and technical specifications. Western Machine Works has been manufacturing shafts for various heavy industries including steel, energy, marine, pulp & paper, construction, and more.

Let’s talk about your project.