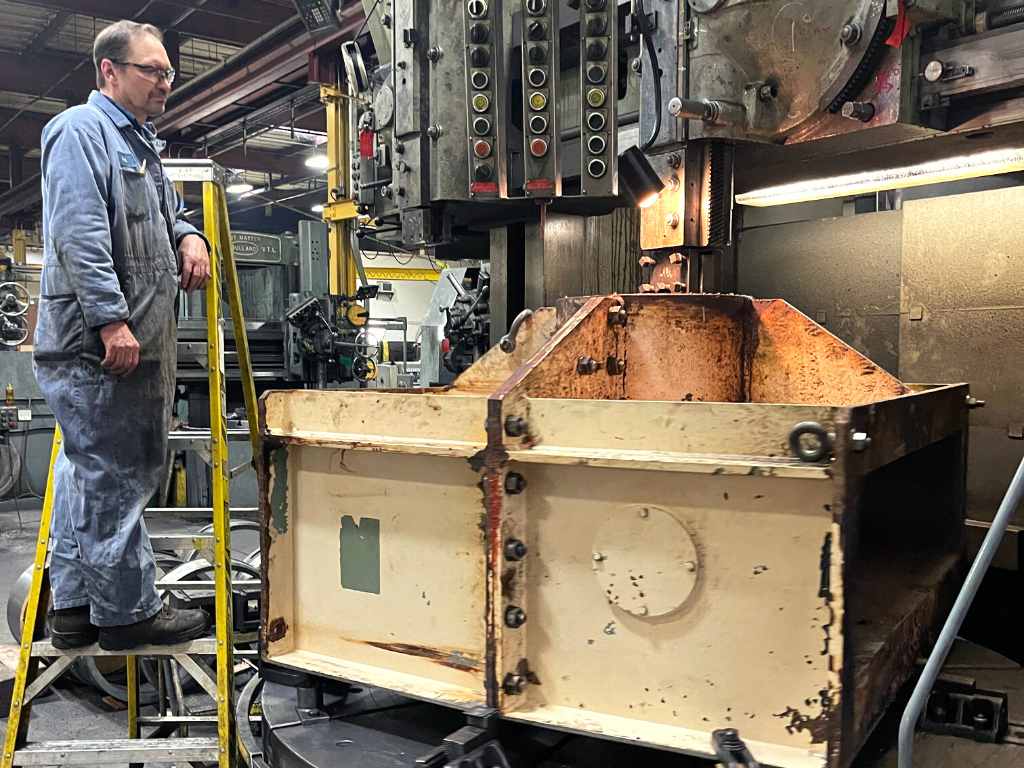

The screw press housing for a paper products manufacturer was severely damaged due to bearing failure. Given its critical role in the dewatering process and overall production, the equipment repair needed to be completed on an expedited schedule. Working closely with our customer and providing daily detailed updates, our team completed all repairs, including manufacturing of multiple new components and precision machining within the assembly schedule.

Project:

- Part: Screw Press Housing

- Details: Bearing failure caused severe damage to multiple components

- Customer: Paper Products Manufacturer

Challenges:

- Several components needed to be manufactured.

- Rush schedule required. Emergency repair was critical to meeting the production schedule.

Engineered Solutions:

- WMW’s sales engineer and project engineers coordinated closely with mill personnel to detail all project requirements.

- Provided formal daily schedule updates to communicate project status to the mill.

- WMW’s design engineering dept. dimensionally inspected existing parts and compared them to mill-supplied OEM drawings.

- Detailed repair prints generated by WMW’s design engineering dept.

- Expedited purchase of required material. All materials were on hand in less than 24 hours.

- Manufactured new thrust collar, housing cap, and shaft spacer on an expedited basis and per stringent technical specifications.

- Large housing bore machined to remove damage and sleeved to re-establish OEM size and tolerances.

- All repairs were completed on time, meeting the mill’s reassembly and production schedule.

- Expedited transportation services were provided to meet the critical timeline.

Results:

- Met all technical requirements.

- Delivered the screw press housing and parts within the emergency production schedule.