FULL-SERVICE MACHINE SHOP WITH ENGINEERING FOCUSED-SOLUTIONS AND RAPID RESPONSE RELIABILITY.

Western Machine Works is a full-range machine shop (NAICS Code 33710) licensed to do business in Washington state and the Pacific Northwest. Our 34,000 square foot machining facility is fully equipped to handle very critical components that require precision machining under very exacting parameters. With 40,000 lbs. lifting capacity and an extensive list of equipment including large lathes, horizontal and vertical milling machines, and CNC machines, WMW can handle large and complex machining projects for a variety of heavy industries.

Western Machine Works specializes in industrial equipment repair & upgrades, component fabrication, custom manufacture, design & engineering, thermal spray coating, precision grinding, and precision machining.

Our Machine Shop Services

Equipment Repair & Upgrades

From your most critical and urgent equipment repair needs to long-term maintenance requirements, Western Machine Works provides reliable and cost-efficient solutions. All repairs and upgrade options are approached from an engineering standpoint to ensure reliability.

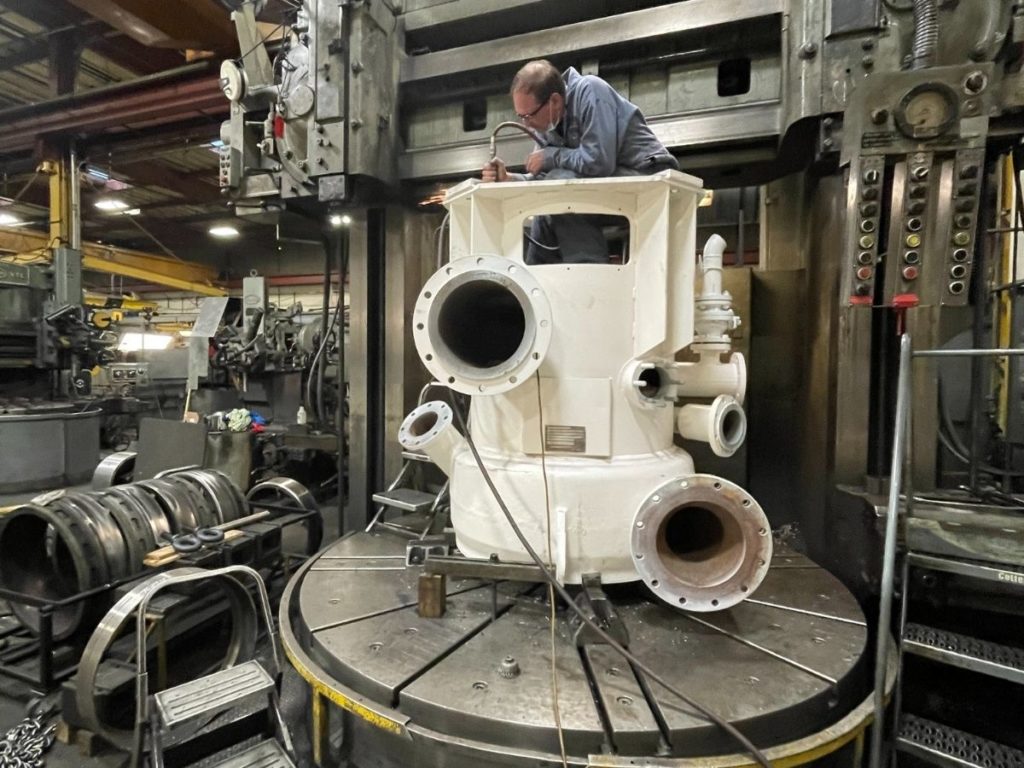

Our facility is well equipped with machine tools to handle small to large projects. Turning capacity up to 78” swing X 478” long, vertical turning capacity up to 120” diameter. Horizontal boring and mill capacity to 40,000 pounds. Most importantly, Western Machine Works employs experienced journeyman machinists and engineers who can tackle any challenging project.

Precision Roll Grinding

We specialize in precision roll grinding and balancing for all types of process rolls and cover types. Your rolls will be returned to OEM standard or better. GEM Superfinish used to assure consistent finish requirements. Industry-best grinders such as Farrel, Lobdell, and Cincinnati are used, along with Pro Mic software, P&J Gauge, and Mitutoyo Surface Roughness Gauge.

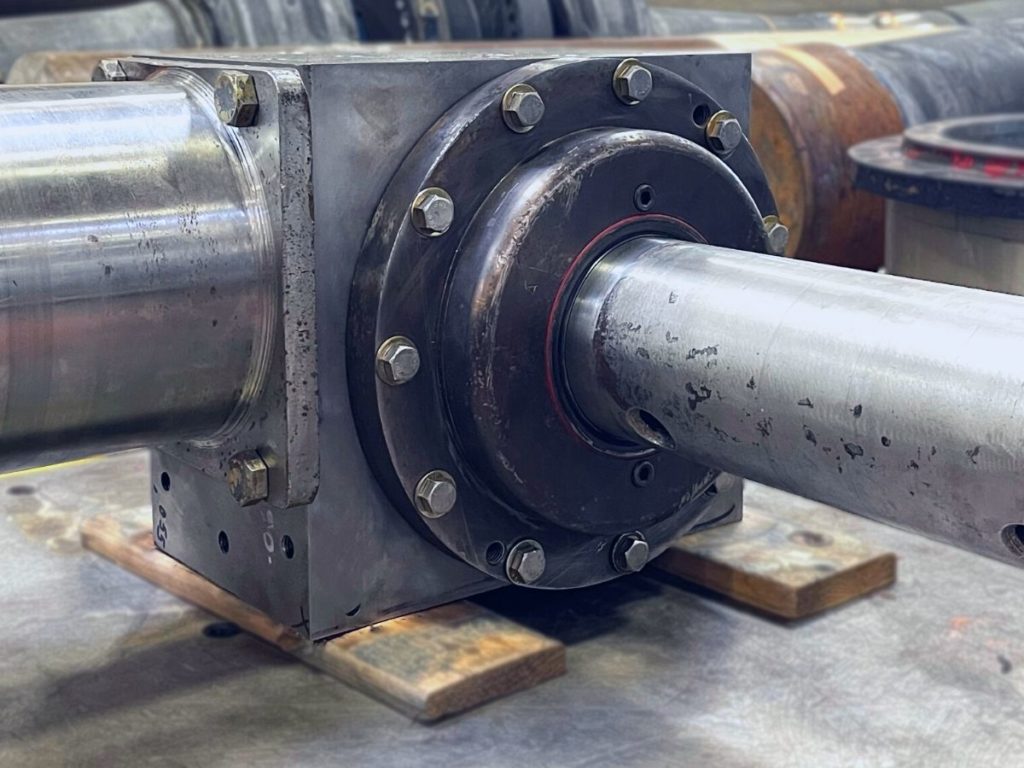

Thermal Spray Services

Utilizing a twin-wire arc thermal spray process, worn out equipment and bearing fits are restored to OEM specifications or better. Your critical equipment is repaired, restored, and reconditioned, at less time and cost compared to a full replacement. The thermal spray process utilizes a 420 Stainless Steel coating material that performs well under compression and resists corrosion and erosion. The resulting bond strength, hardness, and coating integrity are suitable for applications in the wind & hydropower, marine, aerospace, and other critical heavy equipment industries. View technical sheet.

Engineering services

Engineered solutions are built into our process. From our precise measurements of critical dimensions, verification of parameters, inspection and failure analysis, evaluation of inspection data, design, and reverse engineering, our goal is to produce quality workmanship that meets our customers’ needs. We have 3D-CAD capabilities, dimensional inspection and measurement in the field or in the machine shop.

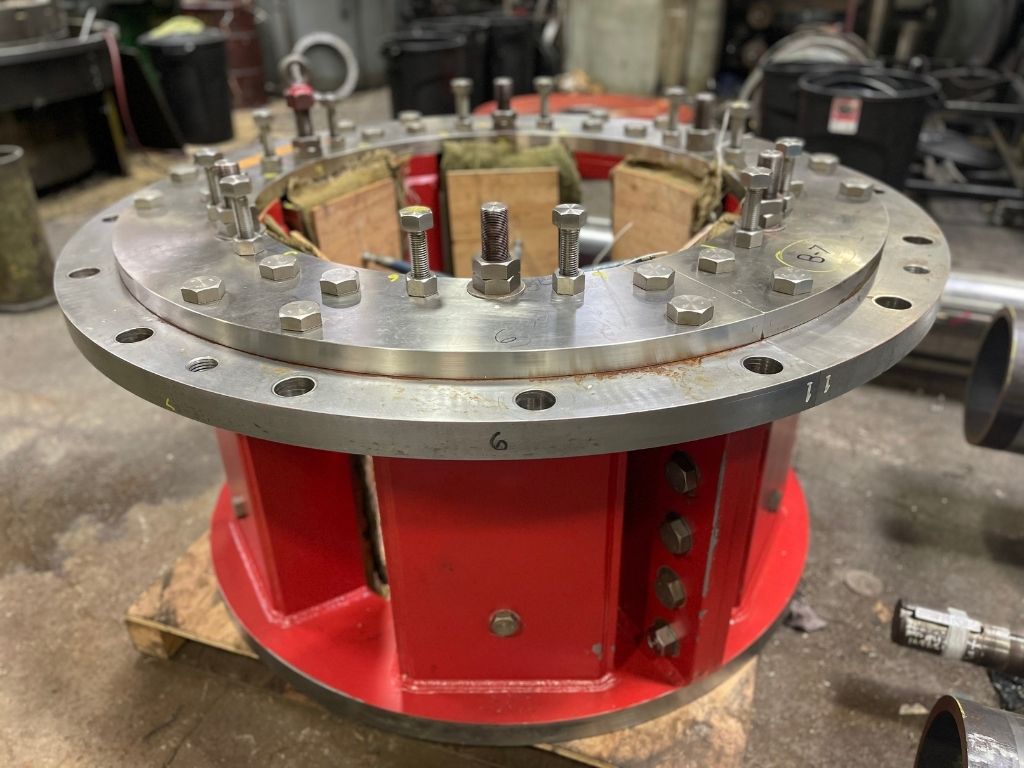

Boring, Milling, Drill Pressing

Our facility has 4 vertical boring mills and 6 horizontal milling machines. Used for turning and boring large cylindrical objects, like water turbine runners, large pipe flanges, and machine turbine casings.

Precision Grinding

Our Farrel Grinder has 44” OD x 312” Face, computer-controlled crowns, 8” superfinisher, and 4” Belt grinder. Tolerance up to .0001” and 4 Ra finish. Our grinding services include OD grinding, honing, superfinishing, and grooving.

Our experienced machinists and technicians are meticulous every step of the grinding process, paying close attention to the machine prep, pre and post-grind measurements, and controlling for deviations.

Dynamic Balancing

Proper balancing is crucially important to any operation that relies on rotating components. Wear and tear, minor damage, and residue can throw balance off on parts such as rolls, turbines, rotors, and shafts. Western Machine Works is equipped to balance components and parts up to 72” in diameter and 320” in length, using the Schenck Trebel balancer.

Precision Machining Services

We provide precision machining of industrial parts and equipment from our state-of-the-art, 34,000 square foot facility in Portland. We provide precision machining to meet dimensional requirements up to .0005” accuracy, including very tight tolerances, finishes, outer diameter (OD), total indicator reading, and inside diameter (ID).

Our Equipment & Skilled Machinists

Our Skilled Technicians are experienced in utilizing the following machines and equipment.

american

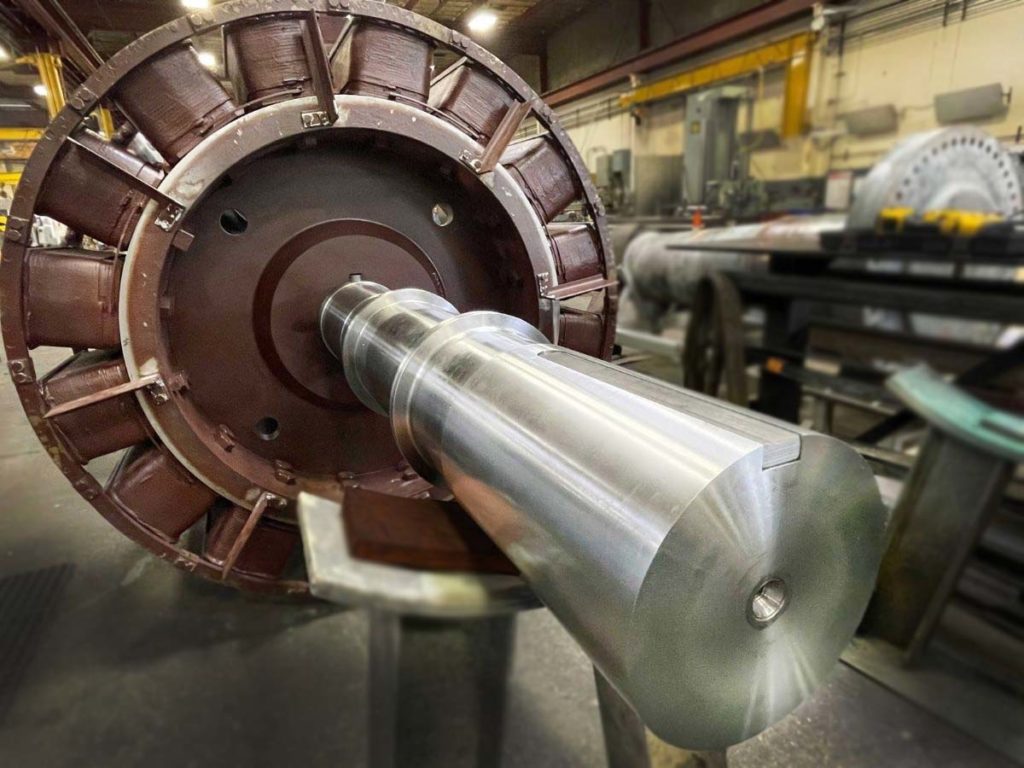

Engine Lathes

Used for precision machining, cutting, and shaping various materials, while rotating the workpiece about an axis. Our engine lathes can handle large critical components such as turbine runner shafts, wind turbine shafts, suction rolls, wind turbine bearings, and ship shafts.

- Max. swing diameter: 78 ¾”

- Between centers: 482”

- Max. Chuck diameter: 62”

- 9 Engine Lathes

- Poreba, Lodge & Shipley, Monarch Engine Lathes

CNC Lathes and Programming

CNC stands for Computer Numerical Control and refers to a machining tool that is operated by a computer system. CNC Lathes are used to produce round shapes with an outer diameter(OD) and inner diameter (ID), and various structures based on precise design instructions and machining specifications.

- Swing over Carriage: 13 ¼”

- Centers: 78”

- Swing over ways: 16”Toolmex

Vertical Boring

machines

Used for turning and boring large and heavy industrial workpieces, such as water turbine runners, large pipe flanges, steel rolls and cylinders, and machine turbine casings. The workpiece is held on a horizontal table that rotates along a vertical axis, while the boring head moves linearly.

- Max. swing diameter: 104”

- Vertical under rail: 85”

- 4 vertical boring mills

- Giddings & Lewis, Bullard Vertical Boring Mills

Horizontal Boring machine

High precision equipment used to modify industrial parts and components by drilling, boring, milling, and grooving various types of steel and alloys in a horizontal direction. It allows for large parts to be machined fast and accurately and also allows machinists to reach small cavities easily.

- 5” Spindle Diameter

- 60” x 120” Table

- 103” Cross Table Travel

- 6 horizontal boring mills

Roll Grinder

machines

High precision machines used to grind smooth and textured rolls and to very tight tolerances. Roll grinding machines consist of a bed, head frame, tailstock, bracket, vertical and horizontal carriage, grinding head, measuring frame, and an electric numerical control system.

- 44” OD

- 312” Face

- Computer controlled Crowns

- 8” Superfinisher

- Farrel, Lobdell Grinding Machines

Dynamic & Static Balancing Machine

Used to balance the moving parts of a machine or piece of industrial equipment by rotating these parts at high speeds or adding various counterweights. Roll Balancing is critical to minimizing vibrations and bearing replacements, optimizing the overall machine performance, and extending the life of the equipment.

- 96” Swing x 552” Length

- 3-Plane Capacity

- Schenck Trebel Balancer

Project Gallery

Hydro Turbine Guide Bearings

A public utility company in Washington needed machining of 2 turbine guide bearings made of lignum vitae wood. Western Machine Works maintained the material’s surface integrity while achieving the required ID, TIR, and RA finish.

Rotor Shaft Machining & Manufacturing

This 850 HP rotor shaft was damaged beyond repair. A new shaft was reverse engineered, manufactured complete, and installed within the customer’s production schedule. The armature bore was machined to 100% concentricity.

Gearbox Repair and Rebuild

A wood processing customer based in Washington needed this silo gearbox repaired and rebuilt, due to chronic failure. No manufacturing prints were available, so our team reverse engineered the parts and assembled the gearbox complete.

Serving Washington State Industries

Western Machine Works has decades-long experience and expertise providing machine shop services to various companies in Washington. Trusted for reliability and durability, our machine shop capabilities have met the equipment repair and refurbishing needs of these very critical industries:

- Wind Power

- Hydroelectric Power

- Pulp & Paper

- Hydraulic Component Manufacturing

- Naval and Commercial Ship repair

- Heavy Equipment Manufacturing

- Non-Woven Manufacturing

- Oil & Gas Generation

- Aerospace

- Transportation

- Construction

- Steel Processing and Recycling

- Mining & Aggregates

our industrial repair facility

Western Machine Works is located nearby the Willamette River. Our 34,000 square foot facility is less than nine miles from Vancouver, WA; about 115 miles from Olympia, WA; and about 180 miles from Seattle. We have helped many Washington-based clients with precision machining in the hydropower, wind turbine, paper and pulp, marine, and manufacturing industries.

Let’s talk about your project.