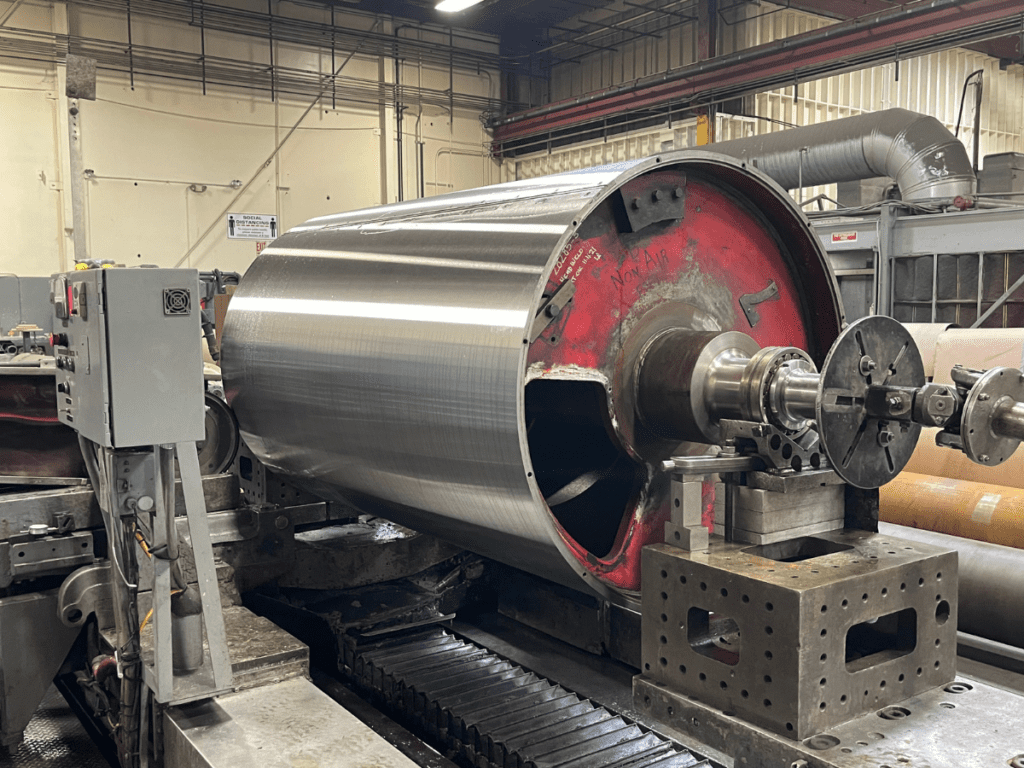

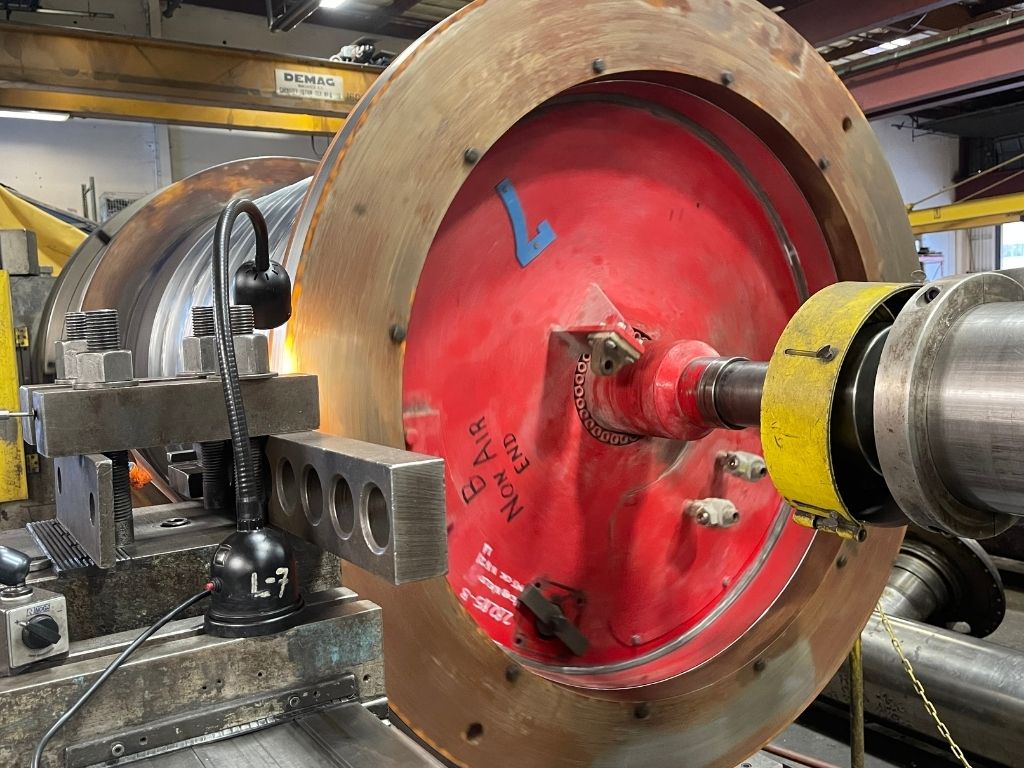

This forming roll needed to be modified and new shafts manufactured to meet new operating requirements. The other option to purchase a new OEM-supplied roll and new shafts would involve longer time and a much higher cost compared to the modifications. Western Machine provided a comprehensive scope of work including precision machining, manufacturing of new shafts, grinding, balancing, and engineering services. As a result, the modified roll and new shafts met all of the customer’s specifications.

Project:

- Part: Forming roll

- Details: 48″ DIA. x 70″ OAL

- Customer: Building materials manufacturer

Challenge:

- The roll’s original design did not allow for easy replacement of shafts. Western Machine’s engineering team designed a rigid cross tube to accommodate the new shafts.

- New shafts needed to be manufactured using a corrosion-resistant 2205 duplex stainless steel material.

- Modify the existing roll face by removing the chrome embossing patterns.

Engineered Solutions:

- Disassembly, inspection, and non-destructive testing.

- Machine both ends of the forming roll in preparation for the carrier rings.

- Design, machine, and install the carrier rings on roll ends to bore shaft fits that would be concentric to the roll face.

- Reinforce the center shaft with a 2″ thick-walled tube. Install and weld on both head plates.

- Bore both ends of the roll to accommodate the new shafts.

- Manufacture and install new stainless steel shafts.

- Grind the roll face to remove the chrome embossing pattern.

- Modify both bearing housings to accommodate the larger shafts.

- Dynamically balance the roll.

- Complete the quality control checklist and prepare the final report.

Result:

- Machined roll and manufactured new shafts met all customer’s specifications.

- Customer saved on capital expenditures by modifying the existing roll vs full replacement.