No matching posts found

Sort By Industry

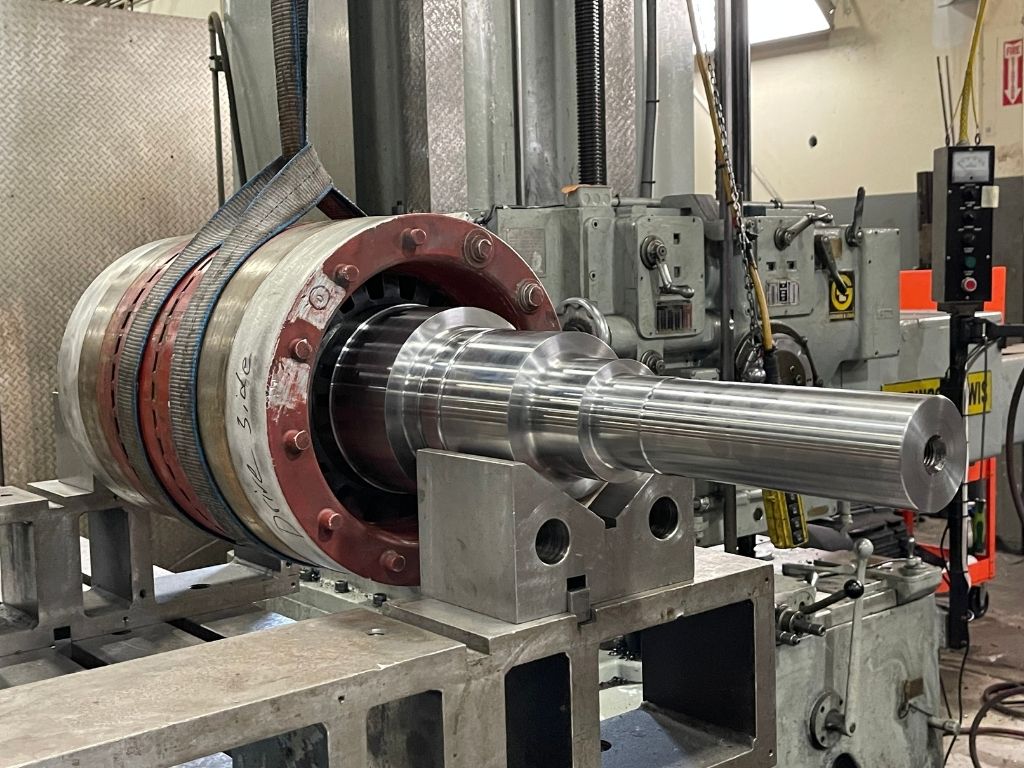

Rotor Shaft – Machining & Manufacturing

The damage to the bearing fit on this rotor shaft was beyond repair. Used for a chemical compressor, the equipment’s concentricity was critical and fast turnaround was required.

Rotor Shaft – Machining & Manufacturing Learn More »

Hydro Turbine Bushings Manufacturing

The slusher runner housing was extensively damaged from bearing failure. Our team manufactured this critical equipment for a paper mill customer without manufacturing prints and drawings in just 5 days.

Hydro Turbine Bushings Manufacturing Learn More »

Slusher Runner Housing Manufacturing

The slusher runner housing was extensively damaged from bearing failure. Our team manufactured this critical equipment for a paper mill customer without manufacturing prints and drawings in just 5 days.

Slusher Runner Housing Manufacturing Learn More »

Hydro component: Gate Shift Ring Fabrication

A hydropower utility customer had a severely cracked gate shift ring. After considering the time line and cost parameters, Western Machine Works’ fabrication solution proved to be the best option.

Hydro component: Gate Shift Ring Fabrication Learn More »

Hydro Turbine Thrust Bearing

A hydropower provider contacted Western Machine Works to machine their newly fabricated hydro turbine thrust bearing to precise tolerance and RMS finish. The fabrication shop they initially contracted failed to achieve the specifications, causing damage to the bearings.

Hydro Turbine Thrust Bearing Learn More »

Gearbox Repair and Rebuild

A wood processing customer needed this silo gearbox repaired and rebuilt, due to its history of chronic failure. No manufacturing prints were available, so our team reverse engineered the parts.

Gearbox Repair and Rebuild Learn More »

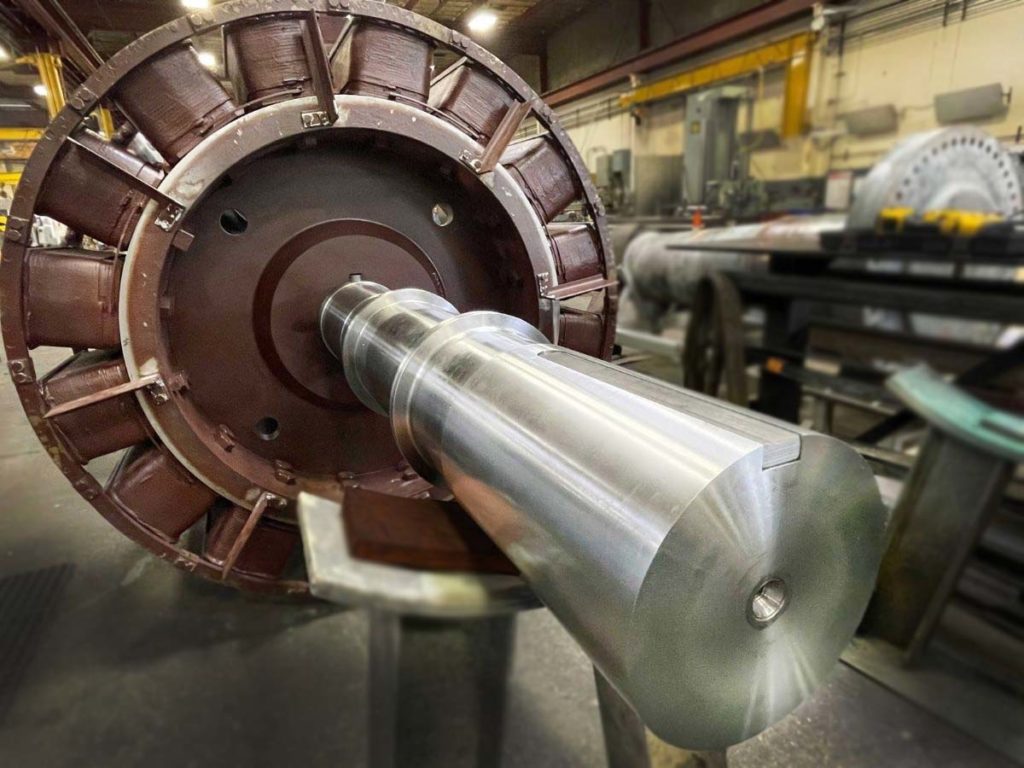

Motor Armature New Shaft Manufacture

The shaft of this motor armature was damaged beyond repair. The WMW team created the manufacturing drawing and manufactured the new shaft and machined the armature bore to 100% concentricity.

Motor Armature New Shaft Manufacture Learn More »

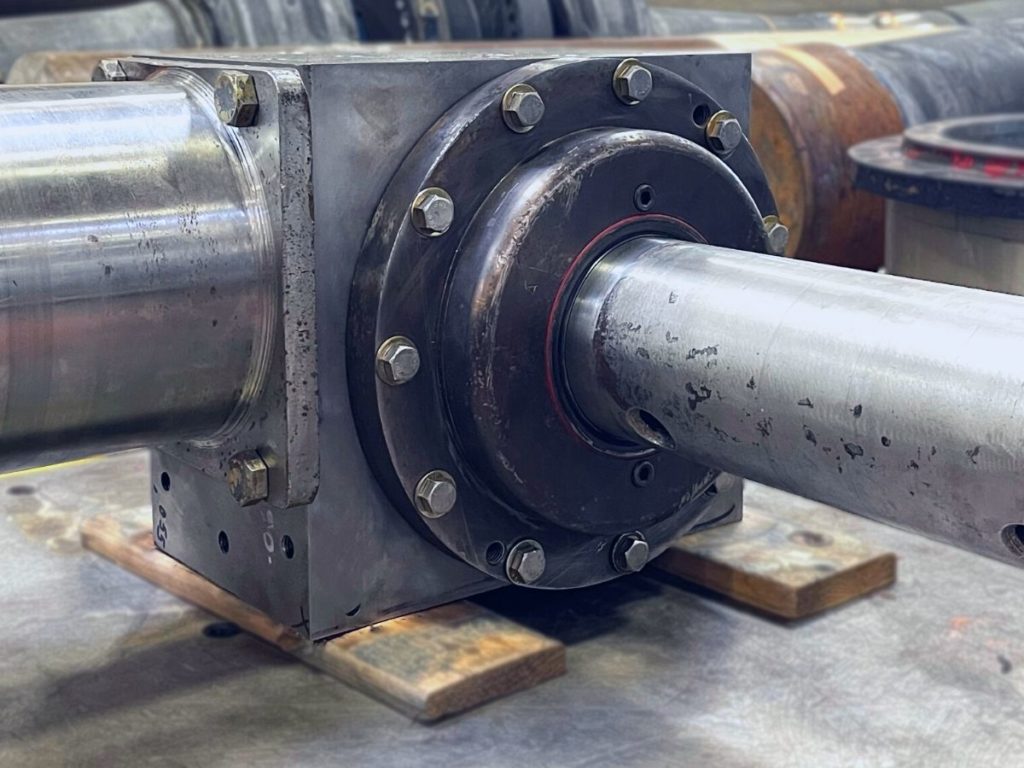

Press Roll Bearing Fit Repair

Customer called over the weekend needing emergency repair of a broken down press roll bearing fit. With WMW’s specialized twin arc metallizing process, the repair was completed and bearing fits restored within 3 days.

Press Roll Bearing Fit Repair Learn More »

Propulsion Shaft Refurbishment

The liners for this propulsion shaft aboard the Kilo Moana, a research vessel operated by the University of Hawaii were severely damaged. Western Machine Works manufactured the new liners and the shaft was certified refurbished by ABS (American Bureau of Shipping).

Propulsion Shaft Refurbishment Learn More »

Hydro Bearing Tub & High Hat Fabrication

These hydro components, namely the bearing tub and high hat were damaged and causing seal failure. Western Machine Works reverse engineered a new high hat and repaired the bearing tub.

Hydro Bearing Tub & High Hat Fabrication Learn More »