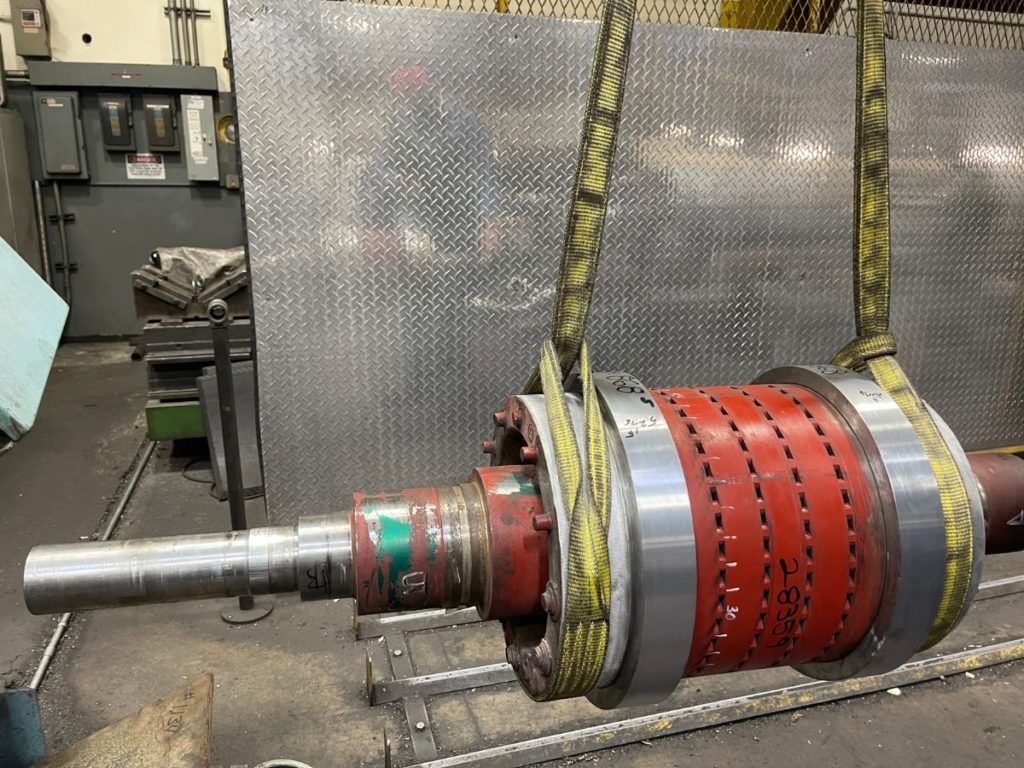

This 850 HP rotor used for a chemical compressor was failing due to a bearing fit damage to the shaft. Western Machine Works inspected the part and determined that the damage was not repairable. A new shaft was reverse engineered, manufactured complete, and installed within the customer’s production schedule.

Project:

- Part: 850 HP Rotor

- Details: 53″ overall length

- Customer: Electric motor distributor

Challenge:

- Bearing fit damage to shaft was not repairable.

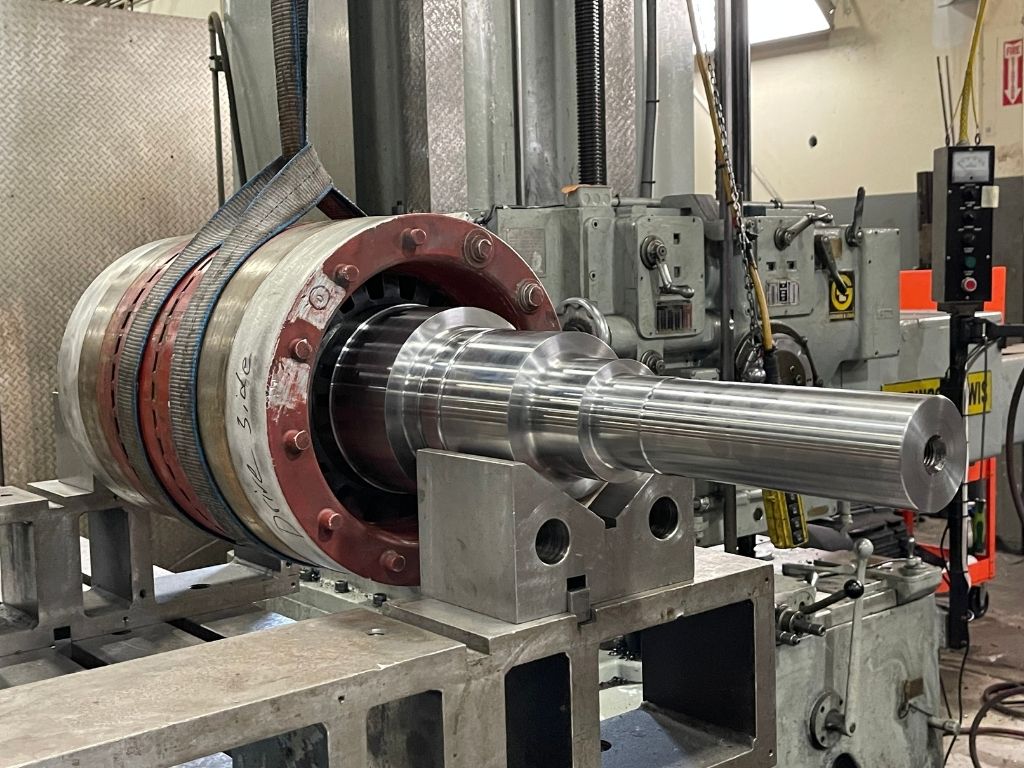

- Bore out existing shaft and manufacture new shaft from 4142 HRHT material.

- Concentricity of shaft and rotor critical.

- Fast turnaround required.

Engineered Solutions:

- Manufacture and install carrier rings for boring out the shaft.

- Bore out the existing shaft and skim cut the rotor bore within .001″ to OD of rotor.

- Reverse engineer the shaft and create CAD drawings of the rotor assembly.

- Manufacture the new shaft complete prior to installation.

- Install the new shaft in the rotor with .003″ interference fit.

Result:

- The new shaft was installed in the rotor complete saving time and cost.

- Concentricity tolerances were achieved.

- The machined rotor and new shaft were completed within the customer’s production schedule.