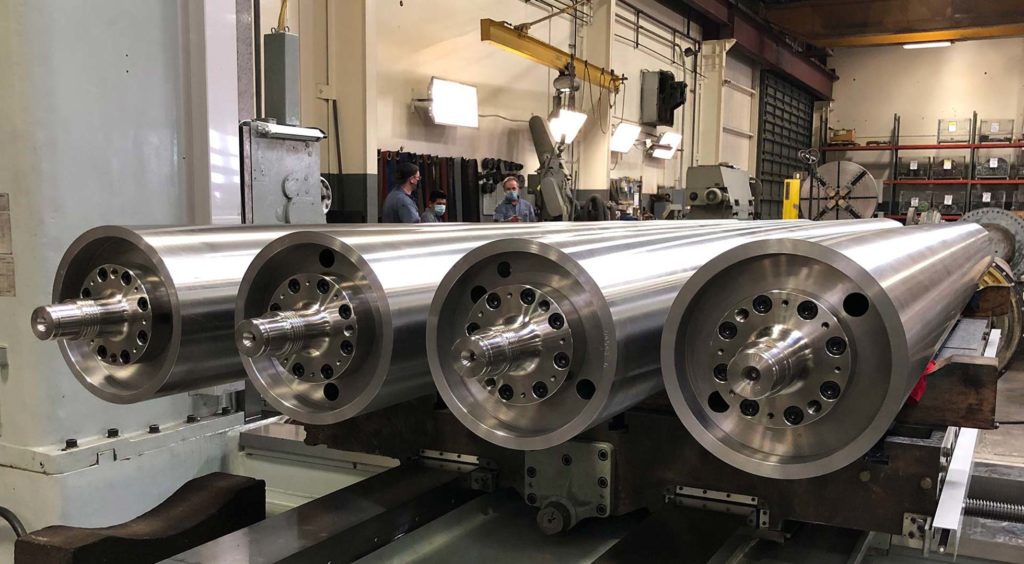

Rolls are critical parts of your production. When rolls suffer damage or break, it can halt operations and impact your bottom line. This is why it is important to have a spare for your process rolls. Having spare rolls on hand in your facility can save time, money, and stress.

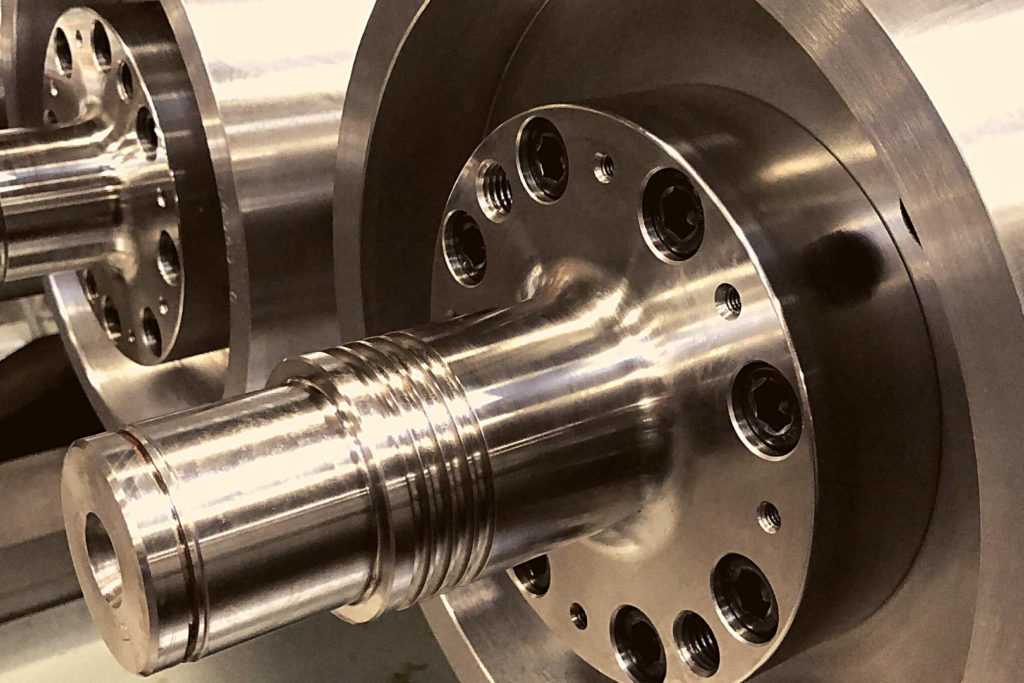

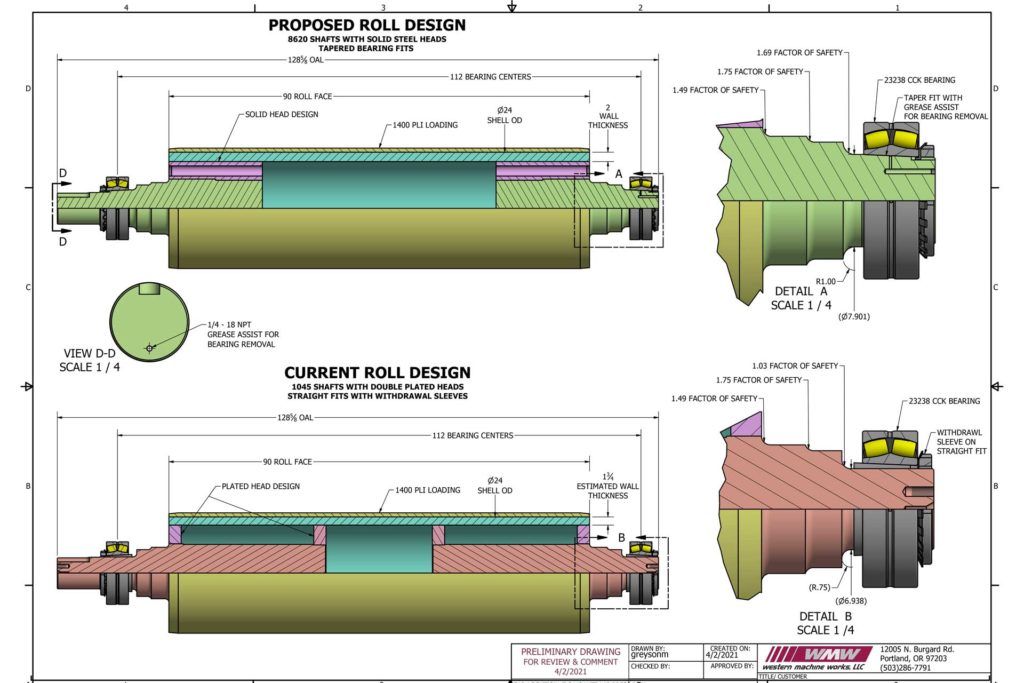

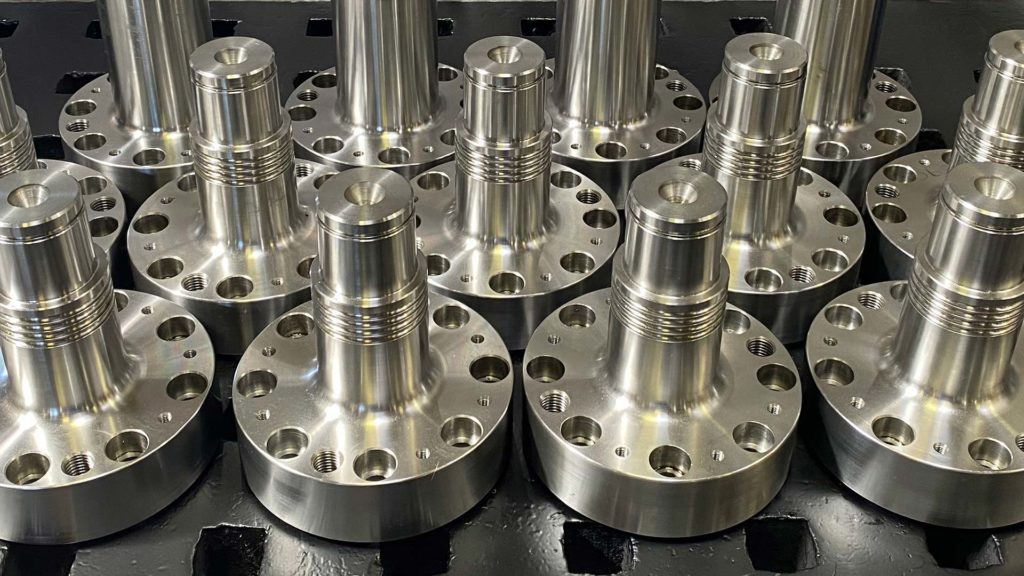

Western Machine Works can design, fabricate, and manufacture a variety of precision rolls, critical rolls, and process rolls based on your requirements, with or without existing manufacturing prints or OEM drawings. Our engineering team can reverse engineer a new roll to match or exceed your current roll’s performance. Our process includes taking detailed measurements of all critical dimensions, creating the CAD drawing, proposal of design enhancements, manufacturing in-house, and managing the process from start to completion.

Western Machine Works has been helping customers meet their production goals through new roll fabrication and manufacturing since 1985.

Types of Rolls We Manufacture

We can manufacture a wide range of rolls, from simple rolls to the most complex:

- Calender Rolls

- Press Rolls

- Breaker Stack Rolls

- Size Press Rolls

- Coater Rolls

- Wire Rolls

- Felt Rolls

- Breast Rolls

- Reel Spools

- Reel Drums

- Couch Rolls

New Roll Manufacturing Services

- On site machine inspection and current running load analysis

- Horsepower requirement survey

- Detailed dimensional inspection and reverse engineer of existing rolls

- Shell stress calculations including bending stress, deflection and crown calculations

- Endurance limit calculations for shafting under reverse bending loads

- Shaft geometry and metallurgical upgrade recommendations

- Bearing life calculations

- Critical speed calculations and vibrations analysis

- New roll design

- FEA Analysis

From start to completion, our team of engineers and technicians focus on our customer’s needs and go above and beyond to high-quality rolls and provide 100% customer satisfaction.

Roll Design and Engineering

Our engineers can design new rolls to meet your requirements and create high-quality rolls to withstand increased load and growing production demands. We back up our proposed roll design enhancements with comprehensive performance simulation tests, shell stress calculations, endurance limit calculations, speed calculations, and bearing life calculations, taking into account material properties, usage and applications and your production goals.

New Roll Manufacturing Projects

Industries We Serve For New Roll Fabrication

- Pulp & Paper

- Packaging

- Nonwoven

- Food Processing

- Steel

- Plastics

- Building Materials

- Construction

Let’s talk about your project.