Our Grinding Specialists Make the Difference

Since 1985, Western Machine Works has been serving Oregon and the Pacific Northwest with precision grinding. Our grinding technicians are highly skilled, experienced, and are able to handle jobs of any size or complexity. Why does this matter? Precision grinding is a people-machine process. The quality of precision grind is dependent not just on the performance qualities of the machines themselves, but also on the skill of the people operating and setting up the machines.

OUR PRECISION GRINDING CAPABILITIES: Tight Tolerances up to +/-.0001″ and 4 Ra finish. We can precision grind any metallic compound, plastics, and various materials and industrial parts.

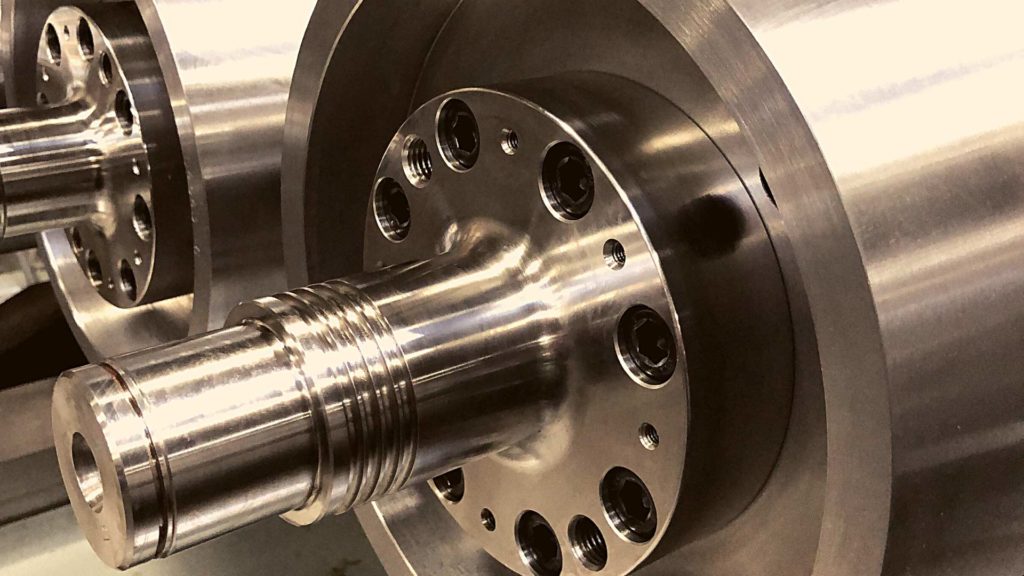

OD Grinding

Outside diameter (OD) grinding is performed on the outside of a cylindrical workpiece that is rotated on a center axis. The grinding wheel and workpiece are rotated in opposite directions. OD grinding is a reliable means to return a cylindrical component to true concentricity. Our machines can grind as large as 44” outside diameter with tolerances of up to .0001″ and 4 Ra finish.

Honing

The honing process is generally only used where an extremely high level of precision and form accuracy is required. Industries that utilize honing include military, commercial, motorsports, aerospace, and medical. Honing can improve the surface texture of a workpiece, eliminating chatter marks and other imperfections.

Superfinishing

Unlike regular precision grinding, superfinishing is done at lower speeds and produces a mirror-like finish. Also known as micro honing, superfinishing creates high geometric correctness (roundness, flatness, straightness) with an accuracy of 2 to 4 microns. Superfinishing is applied after an initial finishing process and leaves an ultra-fine cross-hatch pattern on the surface of the metal.

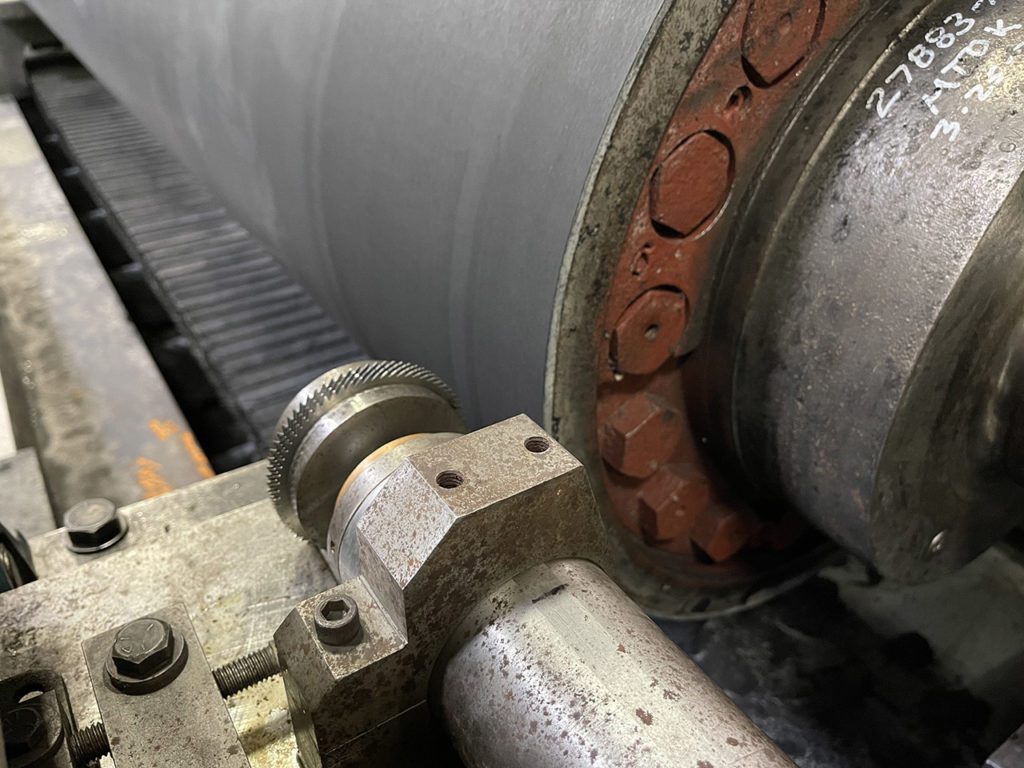

Grooving

In some instances, adding grooves to a workpiece is required. These are usually cut with a hard substance like tungsten carbide. Grooving requires very tight tolerances. Some industries and applications that may utilize grooving are pumps and valves, hydraulics, and pulp and paper.

our high standards for precision grinding

Tight Tolerances up to .0001” and 4 Ra finish.

Meticulous attention is given to pre-grind setup and verifying dimensions and specifications. Our process involves comprehensive measurement and reporting of TIR (total indicated runout or reading), crown, finish, total stock removed, and diameter before and after grinding.

Our PRECISION Grinding Equipment

Machines: Farrel, Lobdell, Cincinnati

Specifications: 44” OD x 312” Face, 8” superfinisher,

4” Belt grinder

Software: Pro Mic

Measurement: P&J Gauge, Mitutoyo Surface Roughness Gauge

What’s the Difference Between Precision Grinding and Blanchard Grinding?

Blanchard grinding, also known as rotary surface grinding, was developed by the Blanchard Machine Company in the early 1900s. Blanchard grinding consists of a rotary table with a magnetic shuck or custom fixture to hold a large workpiece. The machine table spins the workpiece under a vertical grinding spindle, and a segmented grinding wheel is lowered facedown into the workpiece, which leaves the signature Blanchard crosshatch patten. This grinding process can be used for large castings and forgings, large sections of plate stock and stampings, and molds and dies.

Precision grinding is used for tolerances of +/- 0.0001”, and can be applied to a variety of applications. Here are several advantages to choosing precision grinding: 1) It’s precise. As the name makes clear, precision grinding offers exacting accuracy. Fabricators and manufacturers can use precision grinding to replicate the most specific and minute of measurements. 2) It’s versatile. Precision grinding can be used for a variety of shapes and materials, whether flat or curved surfaces. 3) It provides a smooth finish. Precision grinding leaves a smooth finish that meets Ra finish standards based on the workpiece material and application.

Industries We Serve

We provide precision grinding for the following industries:

- Wind Turbines

- Hydropower

- Marine

- Food Processing

- Steel

- Plastics

- Pulp & Paper

- Packaging

- Non-woven

- Wood Products

- Rock Crushing

- Heavy Industries

Let’s talk about your project.