Western Machine Works specializes in equipment repair, upgrades, and manufacture of critical hydro components such as turbine runners, wicket gates, turbine shafts, gate shift rings, and other precision equipment.

Our engineering-focused solutions and responsiveness set our team apart. No matter how complex your project is, our technicians and engineers can provide reliable solutions, with our experience in fabrication, welding, machining, metallizing, balancing, shaft manufacturing, reverse engineering, and project management.

Western Machine Works responds to your emergency or scheduled shutdowns as urgently as possible, with our 24/7 rapid response and in-house transportation capability. We provide cost-saving and time-efficient service options to get your hydropower operations up and running as soon as possible.

hydropower services

Fabrication

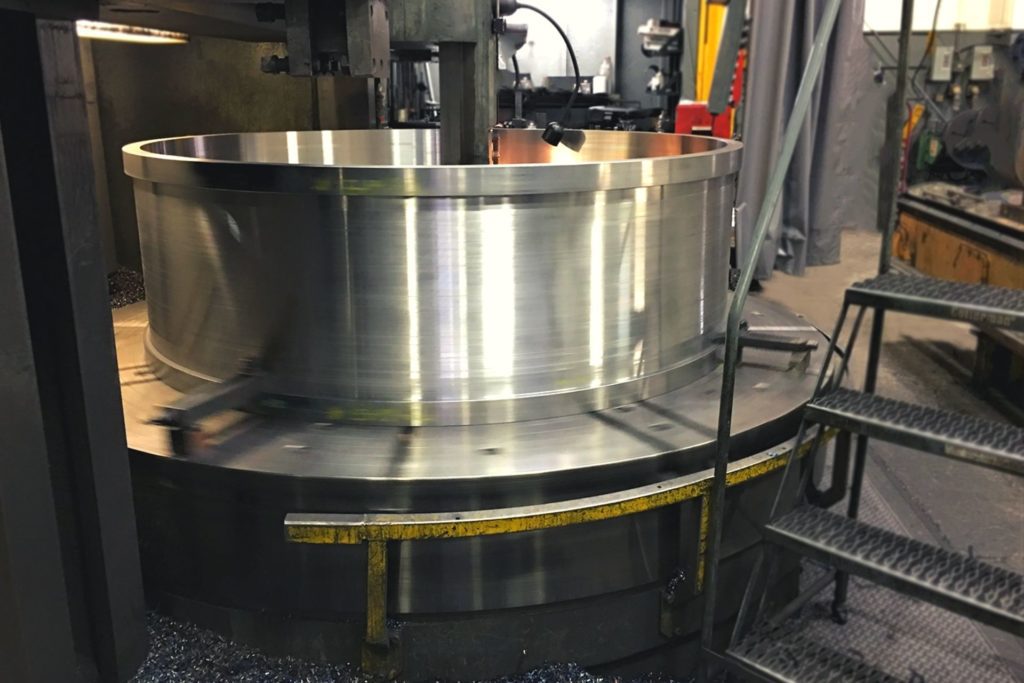

- Experienced in manufacturing hydro components, including gate shift rings, Kaplan turbine throat liners, and other large precision components.

- Newly fabricated components are fit-tested and inspected prior to delivery and installation.

- On-site dimensional measurements of existing components to ensure new parts fit correctly.

Welding Repair

- Welding technicians are certified to meet AWS and ASME standards for repair and for fabricating new components.

- Weld repairs of wicket gates, turbine shafts, and other components to extend the life and reliability of parts.

- Fixtures and positioners are used to rotate parts so weld material is applied uniformly.

Metallizing

- Restoring degraded and damaged components using a twin-wire arc metallizing process with 420 stainless steel coating.

- Parts with severe erosion, corrosion, and wear are repaired and protected.

- Highly beneficial to hydro applications including wicket gates, turbine shaft bearing fits, packing areas, and headcovers.

- Proven reliable and a cost-saving option to OEM replacements.

Dynamic Balancing

- Balancing high speed components at operational speed using a Schenck balancing machine.

- Single components and/or assemblies are balanced to ISO specifications to match your operating parameters.

Shaft Manufacturing

- Manufacturing various shafts including turbine runner shafts up to 485″ long.

- Modifying existing shaft designs to meet updated operating parameters.

- Specializing in tight tolerances to assure smooth operation of shafts and assembled components.

- Includes final dimensional inspection and documentation.

Engineering & Project Management

- Skilled team in designing new equipment and upgrading existing components.

- Providing CAD blueprints, manufacturing drawings, and field measurements of critical dimensions.

- Project management services include assistance throughout the entire project from conceptual planning to re-installation and start up assistance.

Hydro Turbine Repair

Our engineers specialize in hydropower turbine repair, including shaft repair and balancing, as well as brake ring and sleeve fabrication. We have decades of experience with large hydropower projects, the lift capacity and machinery to get the job done, and the engineering team to deliver best-in-class quality.

We can machine and polish bearing fits, re-cut flange faces, fabricate new stator cores, remove old sleeves and manufacture new sleeves, split and weld the sleeves into place, and reapply Babbit coatings to bearings.

Our in-shop repair work will meet OEM specifications or exceed them.

Bearing Repair & Refurbishing

Bearings in hydropower plants must be machined and refurbished in a high-end machine shop to meet required accuracy tolerances. Highly accurate precision equipment is necessary to produce bearings that will work correctly in the field and keep rotating shafts and components from wearing down. Western Machine Works has extensive experience repairing and restoring bearing fits, seals, and surfaces to OEM specifications or better, for our hydropower clients in the Pacific Northwest.

Wicket Gate & Runner Repair

In a hydroelectric facility, the wicket gates control the flow of water to the turbines. These are important components that can determine the efficiency of the hydropower plant. We repair and refurbish wicket gates at our Portland Oregon facility.

Runners are the central components of a hydroelectric turbine. They capture kinetic energy from moving water to turn the turbines and create electrical energy. These usually use blades mounted on a rotating shaft or wheel. Our technicians can refurbish or repair hydropower runners to keep your plant generating power efficiently.

hydro components we service

- Turbine runners

- Turbine shafts

- Wicket gates

- Gate shift rings

- Head covers

- Brake rings

- Discharge rings

- Turbine throat liners

- Thrust bearings

- Generator guide bearings

- Turbine guide bearings

Let’s talk about your project.