Western Machine Works has been a trusted service partner of leading ship builders, ship repair and conversion contractors, and maritime vessel owners since 1985. Our team of skilled technicians and engineers help meet critical dry dock schedule and emergency repairs. We provide fast and reliable precision machining, custom fabrication, weld repairs, thermal spray coating, dimensional inspection, engineering-focused repairs, and project management.

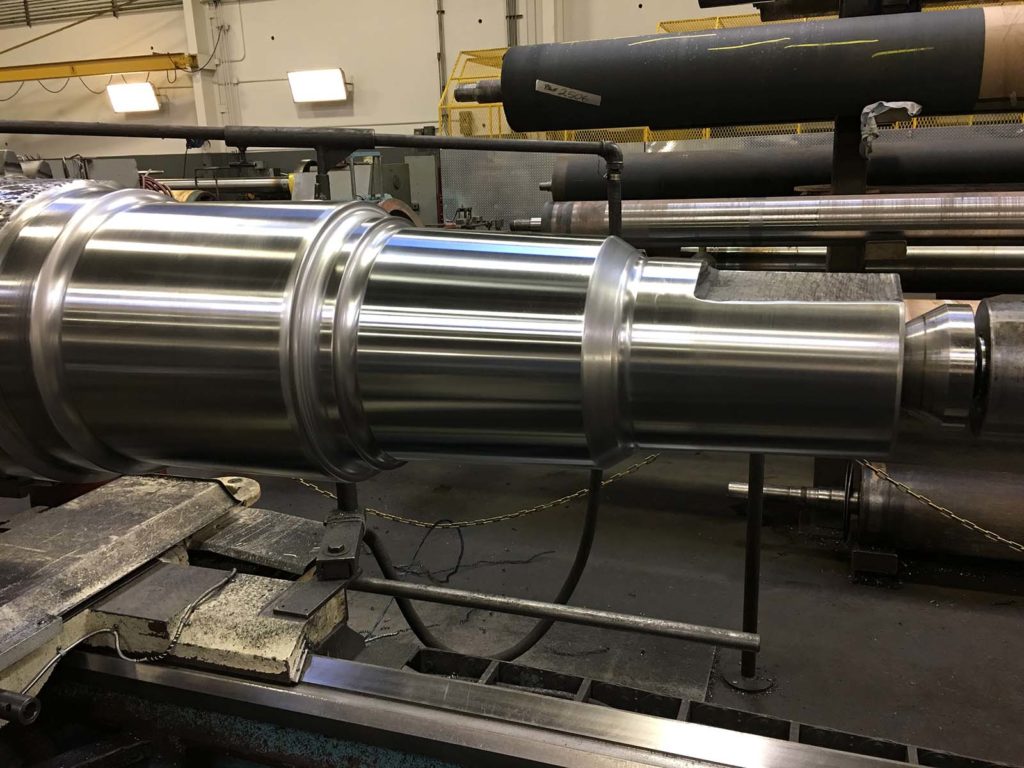

For a recent project, the UH Marine Center had a vessel where the liner fits were badly damaged and the shaft damaged beyond repair. Our team of engineers and skilled technicians manufactured a new ship shaft while providing rigorous non-destructive testing, hydro testing, spark testing, metalizing or thermal spraying, and machining, all under strict standards by the American Bureau of Shipping. Passing the required inspections, the refurbished shaft was approved and certified by ABS. You can read more details on this project here.

Below is a list of the ship repair services we offer from our Portland facility:

Shaft Repair and Refurbishment

Western Machine Works provides shaft repair and refurbishment for various ships and vessels docked in the Pacific Northwest – Oregon, Washington, and Idaho. At our Portland facility, we have the capacity to repair, refurbish, and manufacture new propulsion shafts and rudder shafts that meet stringent standards and certifications.

Propeller Shaft Repair

We can repair and recondition propeller shafts and components, including propeller hubs, caps, and rings. We can machine the parts to your required dimensions and tolerances.

Rudder Shaft Repair

If your rudder shaft is showing signs of grooving, pitting, wear, and corrosion, our shaft engineers can fix it at our facility. We also provide:

- Line boring of rudder bearings

- Machining of rudder blades

- Refurbishing or new manufacture of rudder shafts

- Protective coatings for your rudder shafts

Precision Machining for Marine Vessels and Ships

At our Portland machining facility, we have 34,000 square feet of space, 40,000 lbs lifting capability, and a team of engineering experts to help repair and refurbish critical marine equipment, including propulsion systems and shafts, gearbox frames, rudder shafts, and locknuts.

Our large-capacity equipment and experienced technicians can provide machining to the highest degree of precision, complexity, tight tolerances, and strict parameters. We provide boring, milling, honing, skim cutting, pressing, welding, grinding, balancing, and welding, lathe checks, inspections, fabrication, and manufacturing.

Precision Grinding

Our capabilities for precision grinding and roll grinding are 44” OD x 312” Face, computer-controlled crowns, 8” superfinisher, 4” Belt grinder. Tolerance up to .0001” and 4 Ra finish.

Dynamic Balancing

Roll balancing stabilizes rotating components, like propeller or rudder shafts, by rotating the part at high speed and adding counterweights. This also reduces vibrations, extends the life of the shaft, and optimizes performance.

Our equipment specs:

- 96” Swing x 552” Length

- 3-Plane Capacity

- Schenck Trebel Balancer

Fabrication

If repairing a damaged component is not a viable option, Western Machine Works can fabricate a replacement with or without OEM manufacturing prints. Our team can reverse engineer the part with proposed improvements backed by simulation tests and analyses. From dimensional inspection, fabrication, to certification and installation, Western Machine Works can manage the process to meet your drydock schedule.

Our team works closely with clients to ensure compliance with certification requirements, OEM specifications, and reliability standards.

Thermal Spraying

Using a flame spray or twin arc thermal spray process, a 420 stainless steel coating material is applied to the workpiece to provide resistance to fretting corrosion and improve the surface characteristics. Bearing fits are restored to OEM specifications or better. Thermal spraying can be a cost-efficient way to preserve the component lifespan and avoid costly replacement. More details.

ENGINEERING SERVICES

Our team of engineers oversees your project from start to finish and is experienced in handling complex requirements demanding precision and multi-agency approvals. Our engineering services include dimensional inspection and final reporting, non-destructive testing (NDT), CAD design, and quality control.

Marine Vessel Repair Project Gallery

Engineered Refurbishing – Hydro Servo Parts

shaft & hub refurbishing – ship propulsion system

Precision Machining – Pintle & Bushings

Other Marine Vessel Components We Repair and Refurbish

- Propulsion Shafts

- Propeller Hubs, Caps, and Crank Rings

- Marine Vessel Steering Column Housing

- Steering Column and liner

- Steering Bull Gear & Drive Plate

- Gearbox Frames

- Fin Levers

- Nut bolts

- Rudder Shafts

Let’s talk about your project.