Main Shaft Restoration

Western Machine Works has the skilled technicians, project management, custom tooling, and engineering expertise to handle all aspects of wind turbine main shaft refurbishing and repair. Our windpower repair services include:

- Complete main shaft restoration

- Quick-turn main shaft rebuilds to support repower programs

- Comprehensive dimensional inspection and non-destructive testing

- Enhanced bearing fit repairs using twin arc metallizing process for increased

coating integrity and resistance to galling and fretting - Total main shaft project management

- OEM-certified wind turbine main shaft repair process

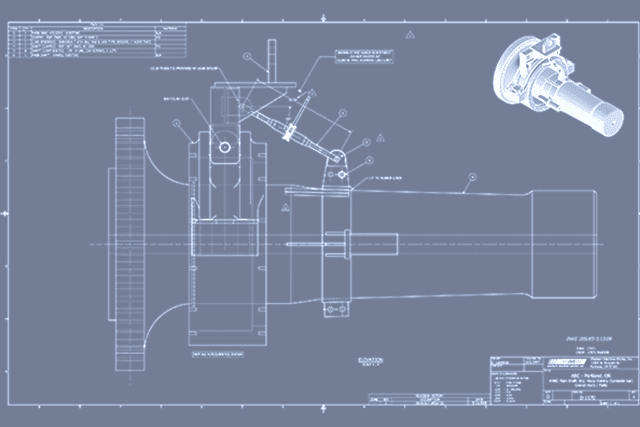

Custom tooling and fixtures are designed to efficiently and correctly assemble main shaft components. Critical dimensions of all main shaft components are documented during the disassembly and inspection process.

Western Machine Works services all major wind turbine brands and is well-equipped to repair the world’s most popular wind turbine models including the Siemens 2.3MW, V82, and GE 1.5MW.

Specialized Solutions for the Wind Power Industry

Engineering

To improve reliability and ensure efficient operation of your main shaft assembly, our engineering team evaluates dimensional data and failure analysis results to determine design upgrades. We also have the in-house capability to reverse engineer and manufacture new components.

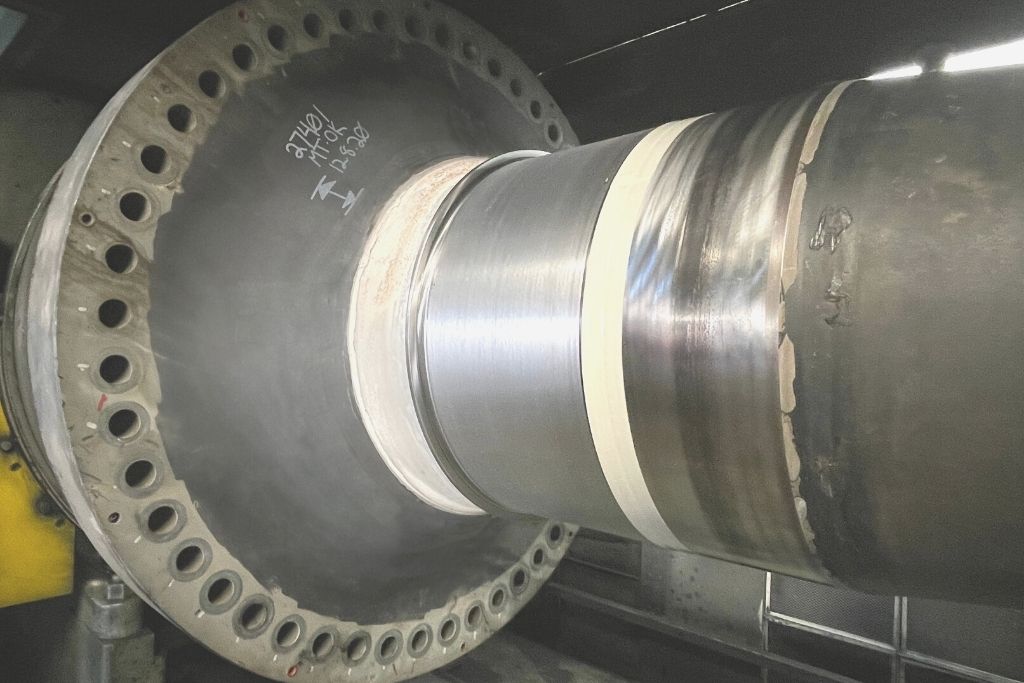

Thermal Spray Coating

Restore the wind turbine’s main bearing fits and worn-out surfaces to factory specifications or better with the two arc thermal spray coating/metalizing process. The two wire arc process uses a 420 stainless steel material with a bond strength in excess of 6000 psi to provide a superior bearing fit surface that is more resilient to fretting and corrosion.

Bearing Evaluation and Analysis

- Main Bearing Cleaning, Inspection and Failure Analysis

- Yaw Bearing Cleaning and Inspection

- Blade Bearing Cleaning and Inspection

- Bearing Housing Restoration

Project Management and Transportation

- Expert technical and logistics project management services allow you to get back to work.

- Custom lifting and transportation fixtures ensure your equipment is protected.

- Company-owned truck fleets ensure prompt, prioritized service.

- Minimize downtime with our 24/7 service.

Wind Turbine Main Shaft Restoration

- Main shaft disassembly and full dimensional inspection

- All main OEM shafts serviced

- Non-destructive testing of all components

- Bearing fit repairs

- Sourcing for unique bearings and sealing components

- Remachining to accept custom undersized bearings

- New shaft manufacture.

New Wind Turbine Component Fabrication

- Measurement and documentation of all critical dimensions

- CAD modelling

- Creation of manufacturing prints

- In-house machining and fabrication for shorter lead time and cost-efficient option

- Quality control and inspection before delivery

Wind Turbine Capabilities

Servicing All Major Wind Turbine Brands

| Siemens |

|---|

| SWT-2.3-93 |

| SWT-2.3-101 |

| SWT-2.3-108 |

| Vestas |

|---|

| V82-1.65 |

| V80-1.8 |

| V80-2.0 |

| V47-0.66 |

| V100-1.8 |

| Mitsubishi |

|---|

| MWT600 |

| MWT62/1.0 |

| MWT95/2.4 |

| GE |

|---|

| GE1.5-77 |

| GE1.7-103 |

| GE2.0-116 |

| GE2.5-100 |

| Other Brands |

|---|

| MM92 |

| S88 |

| G58-0.85 |

| G90-2.0 |

NOTE: This is a partial list of the turbines that we support. Contact us for a free consultation and quote for your specific wind turbine model.

Maintenance of Wind Turbine Shafts

Wind power usage is projected to grow 10% over the period from 2020 to 2025. Renewable energy still competes with energy sources like fossil fuels, solar, and hydro for energy production. Keeping costs low is crucial for wind turbine efficacy and wind power adoption. Regular wind turbine maintenance helps keep costs down energy production up.

Rotating components, like shafts and bearings, are where most of the wear and tear occurs. Tolerances can increase over time from regular wear and corrosive compounds in the air (especially if the wind turbines are near a coastline). As the tolerances on the shaft and bearing become greater, the bearing fit loosens. This can also be accelerated by vibrations that increase as tolerances grow. In extreme cases, bearing failure can occur, which may necessitate shaft and bearing replacement, which halts energy production and increases cost to the wind farm.

By regularly scheduling maintenance on aging components, resurfacing the shafts to OEM specs, and balancing the shafts, efficiency is increased, and downtime is limited to scheduled windows of time.

Wind Turbine Main Shaft Repair Process

Project Gallery

Wind Turbine Services

- Main Shaft and Primary Bearing Disassembly

- Complete Dimensional Inspection of All Main Shaft Components

- Non Destructive Testing of Main Shafts

- Bearing Inspection and Failure Analysis

- Bearing Seat Grinding to Next Size Bearing

- Bearing Housing Restoration

- Complete Re-assemblly of All Main Shaft Components

- Expedited Repair Schedules to Accommodate Crane Schedules

- Custom Lifting and Transportation Fixtures

Let’s talk about your project.