Mechanical engineering services include failure analysis, reverse engineering, component redesign, industrial equipment upgrades, and project management services.

Western Machine Works has the engineering capabilities and expertise to design new equipment or upgrade your existing machinery while adhering to precise requirements and rigourous standards. Partnering with Western Machine Works provides project confidence and reliability.

Increase Your Engineering Resources

Our engineering staff has in-depth knowledge of equipment design and repair. We’ve completed various projects from roll design and refurbishing to new equipment design and installation. Western Machine Works provides a turnkey solution for all your plant performance needs, including reverse engineering of existing components.

Our local staff of highly trained engineers works side by side with your team and is available for site visits with short notice. This type of local, hands-on support and management helps keep projects on schedule and within budget.

Turnkey Project Management

A single-source solution that requires minimal input or supervision by your staff. We minimize your time involvement by handling the entire project from removal, to repair, to installation.

Let us know your objectives, and we’ll handle the rest—everything from conceptual drawings to collecting and verifying dimensional measurements to final manufacturing. We’ll even provide technical assistance at the time of installation.

Inspection and Root Cause Failure Analysis

Our technicians inspect every industrial equipment component that we restore or replace. We look for excessive wear, evidence of cycle fatigue, damage due to machine vibration, and the root cause of sudden component failure. In many cases, Non-Destructive Testing techniques are used to verify component integrity.

After a thorough inspection and analysis, we provide you the full report for review. We work with you closely to put together a plan that best fits your budget and timeline.

Reverse Engineering of Existing Equipment

Our engineering staff has the expertise to take critical measurements and determine the performance characteristics of existing equipment. This can then be used to:

- Create engineering drawings that define specifications

- Repair or replace components

- Decrease lead times to meet your production schedule

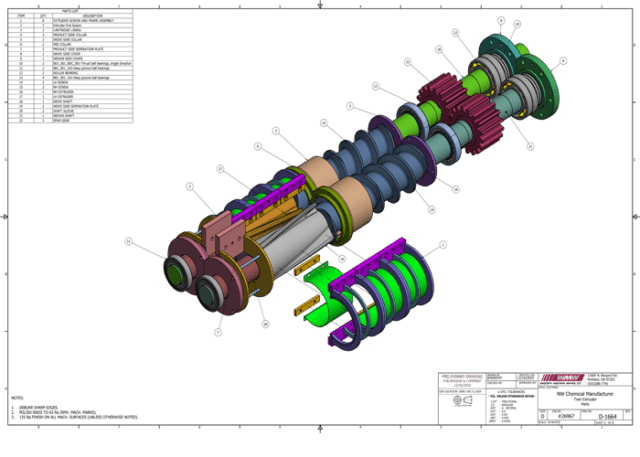

Engineered Repairs and Upgrades

We don’t just fix your equipment, we improve it, with our engineering-based solution from start to completion. Using non-destructive testing methods, we inspect and evaluate the damage, measure critical dimensions, provide accurate documentation, analyze results, and identify the cause of failure. We then recommend cost-effective solutions either for repair or refurbishment to extend the reliability and performance of your equipment.

New Equipment Design

When repairing existing equipment is not enough to meet your performance or reliability goals, our experienced engineering team can design new equipment that meets your specifications.

Let’s talk about your project.