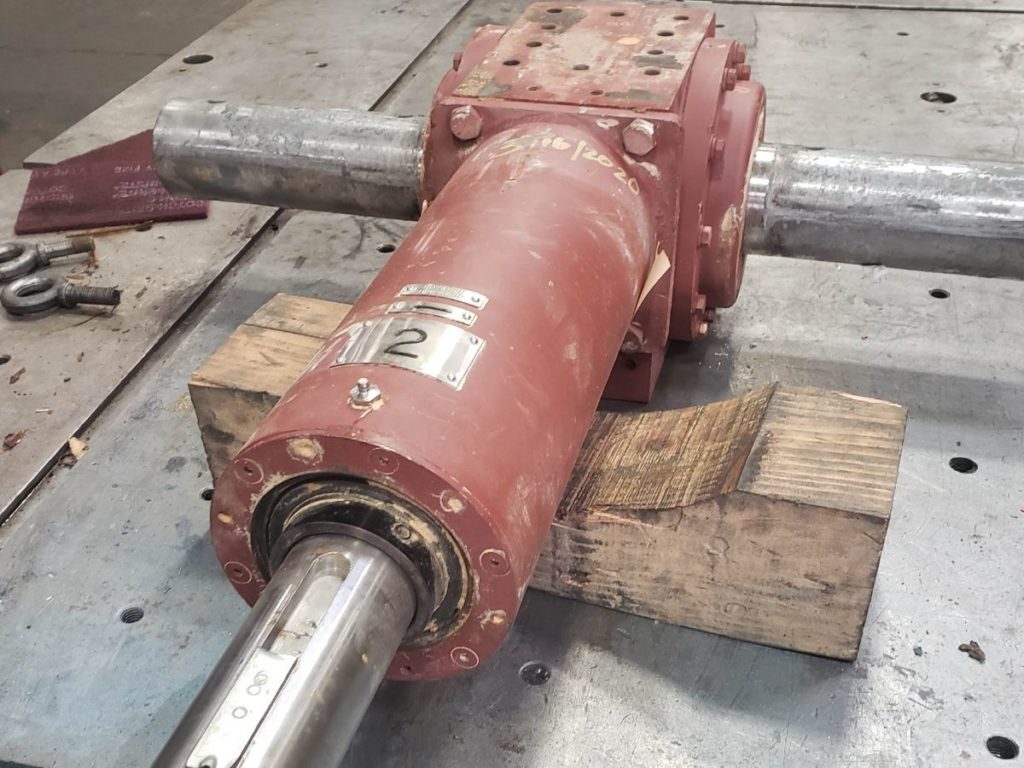

This project involves the manufacture of a new gearbox housing and input shaft for a wood processing company. The silo gearbox was damaged beyond repair and required non-destructive testing, machining, metallizing, and rebuild. No manufacturing prints were available, so our team reverse-engineered the new parts.

Project:

- Part: Silo Gearbox

- Customer: Wood Processing

Challenge:

- Gearbox was damaged beyond repair.

- No manufacturing print was available.

Engineered Solutions:

- Disassemble and dimensionally inspect all critical fits.

- Non-destructive test the gearbox housing for cracks and/or defects.

- Manufacture a new gearbox housing from welded and stress relieved fabrication that is stronger than original cast gearbox.

- Manufacture a new input shaft.

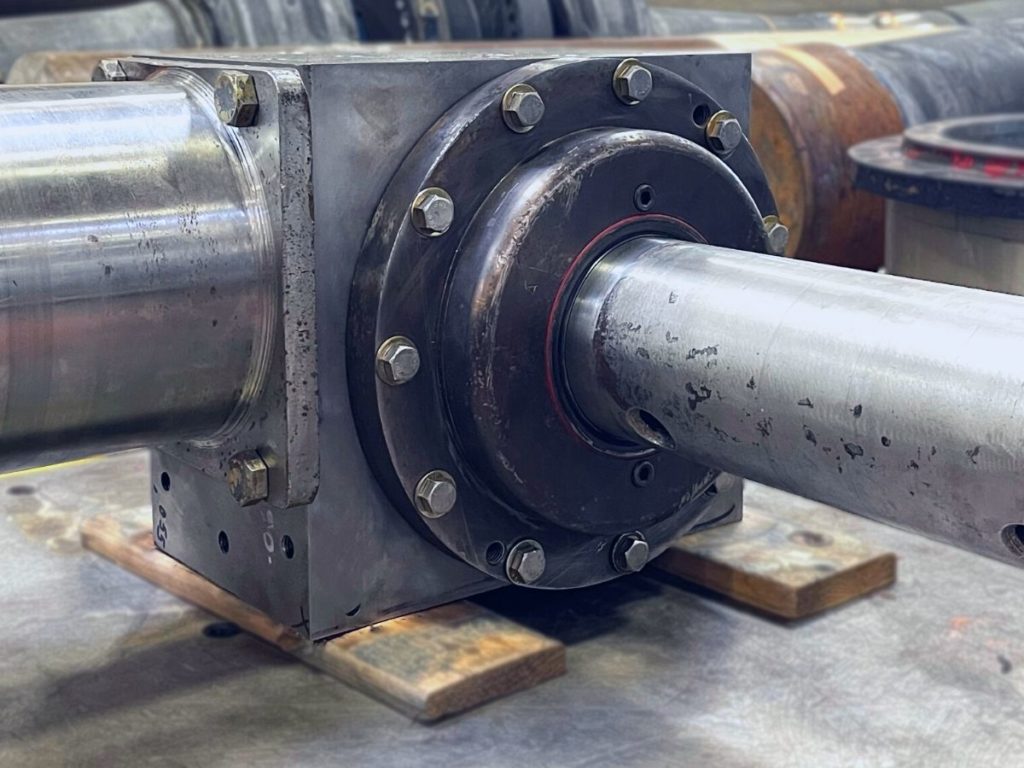

- Manufacture a new pinion gear bearing cartridge.

- Manufacture a new pinion gear spacer sleeve.

- Metallize the bearing fits on the output shafts and finish machine to specifications.

- Machine/modify the pinion gear to accept the retaining nut.

- Assemble the gearbox complete.

- QC inspection prior to shipping. Gearbox was installation-ready upon delivery to customer.

Result:

New gearbox housing and shaft were manufactured with improved reliability and performance.