A hydroelectric plant in Oregon needed new Kaplan runner hub bushings to optimize its power output and its long-term reliability. Western Machine Works manufactured all new outer trunnion bushings, inner trunnion bushings, link pin bushings, upper piston rod bushings, lower piston rod bushings, and coupling bolts, and reverse engineered the trunnion followers. To ensure the installation and operation go smoothly, Western Machine Works also line bored the bushings and checked concentricity of all the bushings to the turbine housing.

Project:

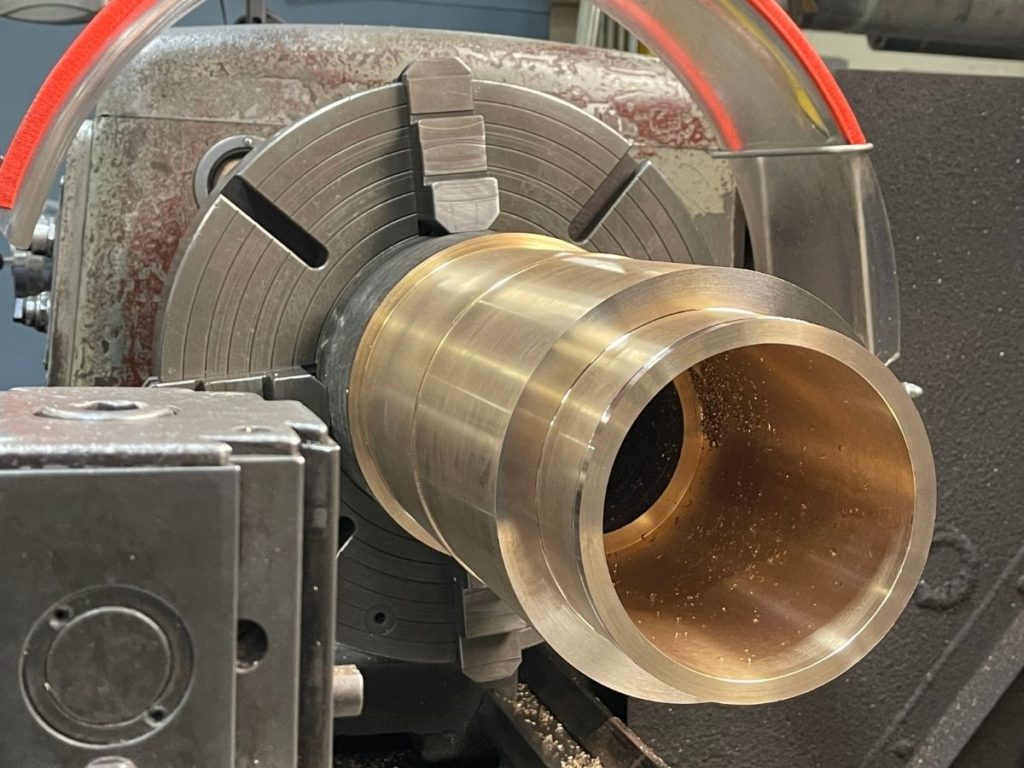

- Part: Kaplan runner hub bushing replacement

- Details: C932 bronze material

- Customer: Hydro refurbishing contractor

Challenge:

- Fabricate new bronze trunnion, link pin, and piston rod bushings, trunnion followers, and coupling bolts.

- Runner hub concentricity for bushing bores exceeded .008″ and required line boring.

- Fast turnaround required.

- Fabricate bushings to OEM specifications.

Engineered Solutions:

- Initiate CAD machining drawings to ensure bushing machining dimensions were correct.

- Fabricate trunnion bushings and add oil grooves as per customer direction.

- Concentricity checks on runner hub in bushing bores indicated bushings required line bore to ensure .003”-.005” bushing running clearance was achieved.

- Design and create CAD drawings to fabricate followers.

- Measure and fabricate new 4140 coupling bolts.

- Sandblast and apply epoxy coating.

- Fabricate mud ring for runner nose cone assembly.

- QC inspection prior to shipping.

- Clean and prep for shipping.

Result:

- Turbine runner blades were installed and desired running clearance was achieved.

- Machine assembly and hydraulic testing indicated smooth operation of runner hub assembly.

- Project completed within customer operating schedule and budget.