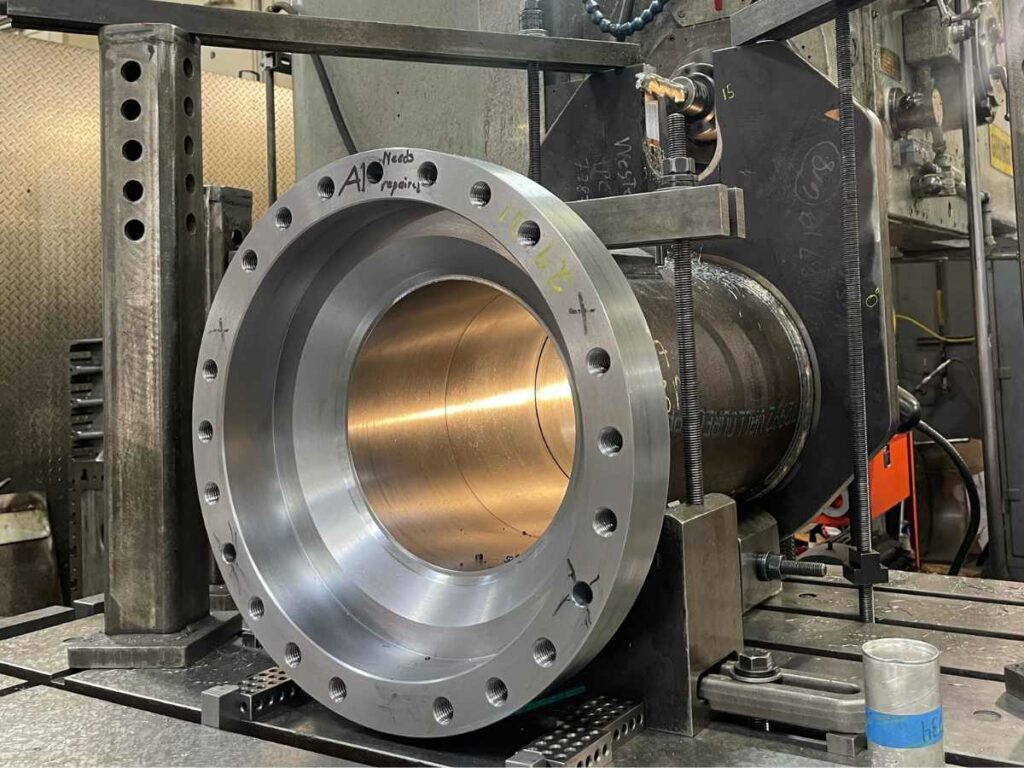

The upper pinch roll housing for a steel roll manufacturer was damaged beyond repair. Adding to that challenge, there were no OEM prints available to be used as reference for the fabrication and machining. Our team reverse engineered the part, dimensionally inspecting the existing component and generating the manufacturing prints while verifying all critical fits and dimensions. The new rolling mill housing was fabricated and machined based on our engineering team’s drawings. After completing all machining and meeting all technical requirements, the new bearing sleeves were installed into the housing. The manufactured new rolling mill housing was delivered machine-ready within the production schedule.

Project:

- Part: Upper pinch roll housing

- Details: A572 material, 650 lbs.

- Customer: Steel roll manufacturer

Challenges:

- Upper pinch roll housing was severely damaged. Repair was not a viable option.

- No manufacturing prints were available.

Engineered Solutions:

- Reverse engineering of the existing upper pinch roll housing.

- Dimensional inspection and verification of all critical dimensions and specifications.

- Create CAD drawings and manufacturing prints.

- Machine tube, ring, and large plate per WMW engineering’s manufacturing drawing.

- Fabricate housing per WMW drawing.

- Machine, mill, and drill housing per WMW drawing.

- Install customer-supplied bearing sleeves into the housing

- Quality inspection before shipping.

- Painting and prep for shipping.

- Transportation to and from customer site.

Results:

- All technical specifications were achieved.

- New upper pinch roll housing was completed and delivered within the production schedule.