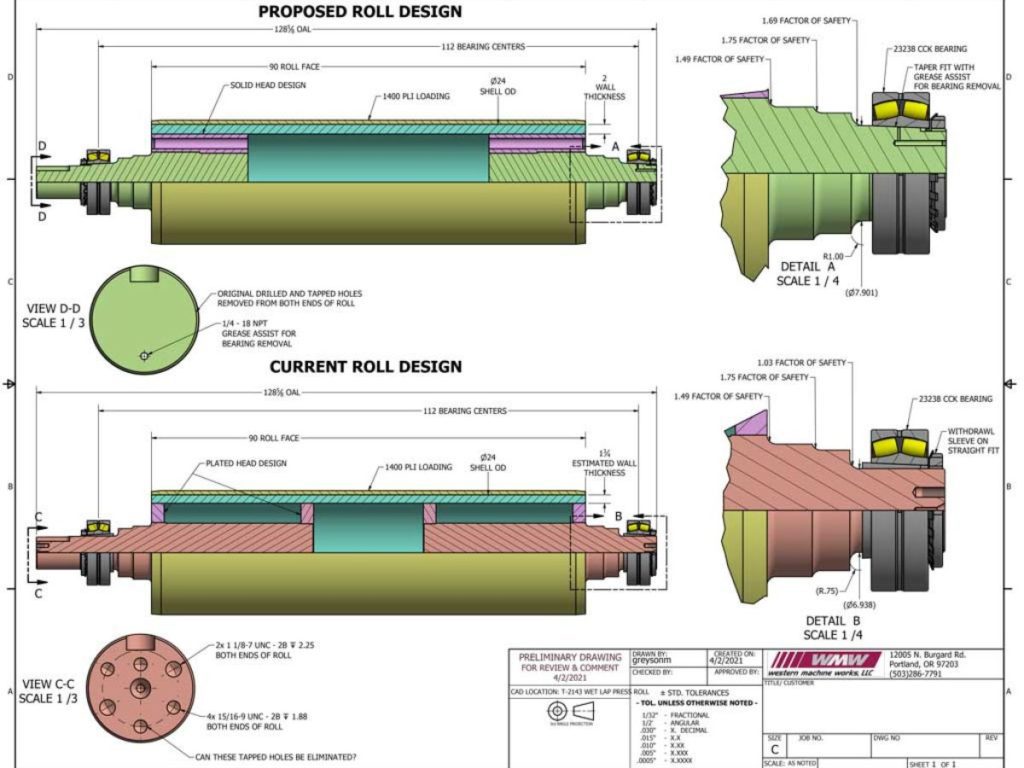

One of the leading global manufacturers of paper products consulted with Western Machine to upgrade and manufacture a new roll that can meet current loading and operating parameters, and machine chemistry. Our team worked closely with the customer to design a new roll with a new plated head design, increased wall thickness, and grease assist for easier bearing removal. The new roll was manufactured completed and delivered machine ready.

Project:

- Component: Press roll

- Details: 128.635″ overall length, weighs 4 tons

- Customer: Global manufacturer of paper products

Challenges:

- Shafts on existing roll cracked due to collision and applied load.

- The existing roll design did not allow for shaft replacement.

- OEM drawing was not available.

Engineered Solutions:

- WMW engineers worked with the customer to determine current roll loading and machine chemistry.

- Prior roll was dimensionally inspected to create preliminary design drawings.

- Prior roll design was analyzed via FEA and Endurance limit calculations.

- Roll shell and shafting were determined to be inadequate for current machine loading and chemistry.

- Roll design was modified to withstand current loading.

- Shaft material was selected to meet loading criteria and machine chemistry.

- New roll was manufactured complete including new roll cover, grinding, and dynamic balancing.

- Roll was assembled with bearings and housings and delivered to the customer “machine ready.”

Results:

- Upgraded roll design increases roll performance to meet demanding production requirements.

- Long-term cost savings and asset protection.