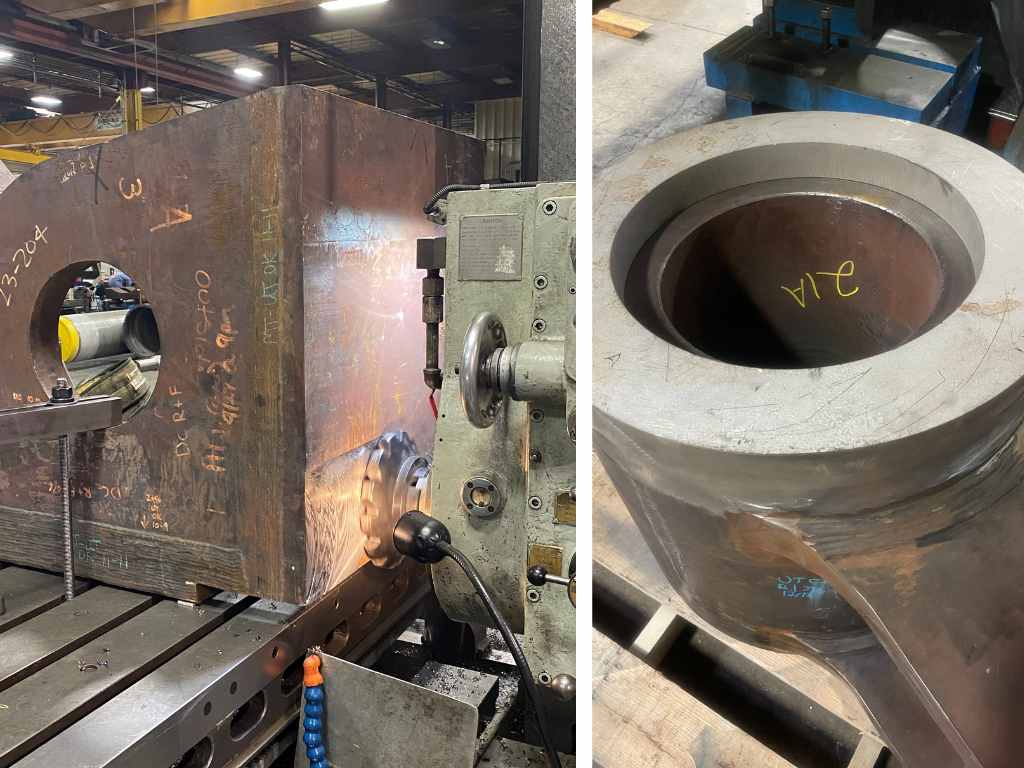

Trunnion yoke and hubs were machined to OEM specifications within a 3-day emergency timeline. The components were part of a hydro dam assembly that required urgent repair.

Project:

- Part: Trunnion Yoke + Hubs (2x)

- Details: Hub assembly and yoke were heat treated per AWS D1, 5

- Customer: Industrial Equipment Manufacturer

Challenges:

- Emergency response and round-the-clock machining schedule.

- Complex pre-machining setup.

- Stringent technical specifications for the bore dimensions, height dimensions, tolerances, and Ra finishes.

Engineered Solutions:

Trunnion Yoke:

- Machine base plate prior to machining to ensure flatness.

- Line bore holes per print and ensure parallelism.

- Machine surfaces per print and Ra finish.

- Drill and tap 4 places on the side.

- Machine 2 drain pockets on the base.

- Record dimensions prior to and after machining.

Trunnion Hubs (2x):

- Setup in vertical and ensure bottom face is true.

- Machine top of hubs per OEM print.

- Machine bore per OEM print.

- Record height dimensions, tolerance, and Ra finish before and after machining.

Results:

- All OEM specifications were achieved.

- Completed all machining within a 3-day rush repair schedule.