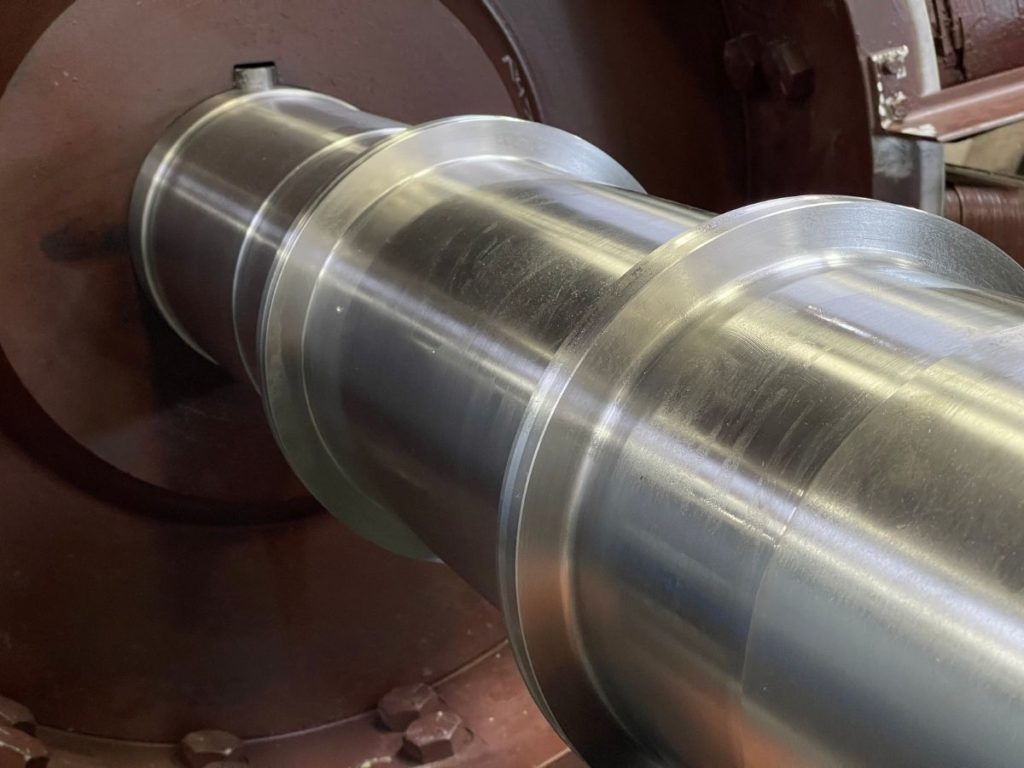

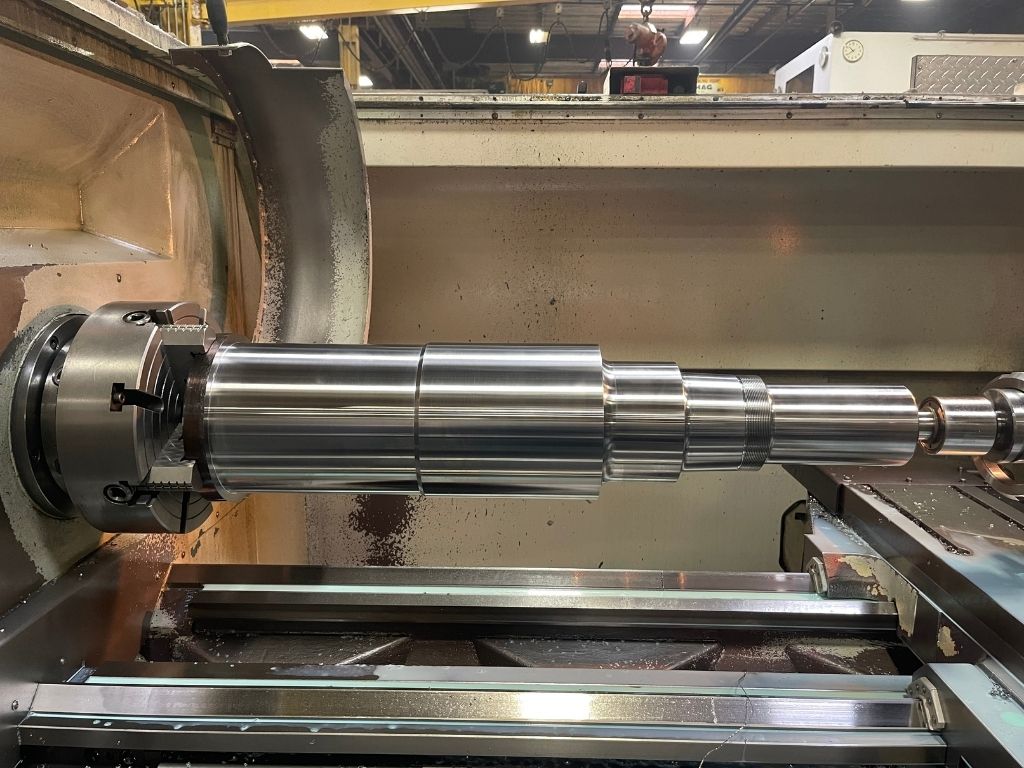

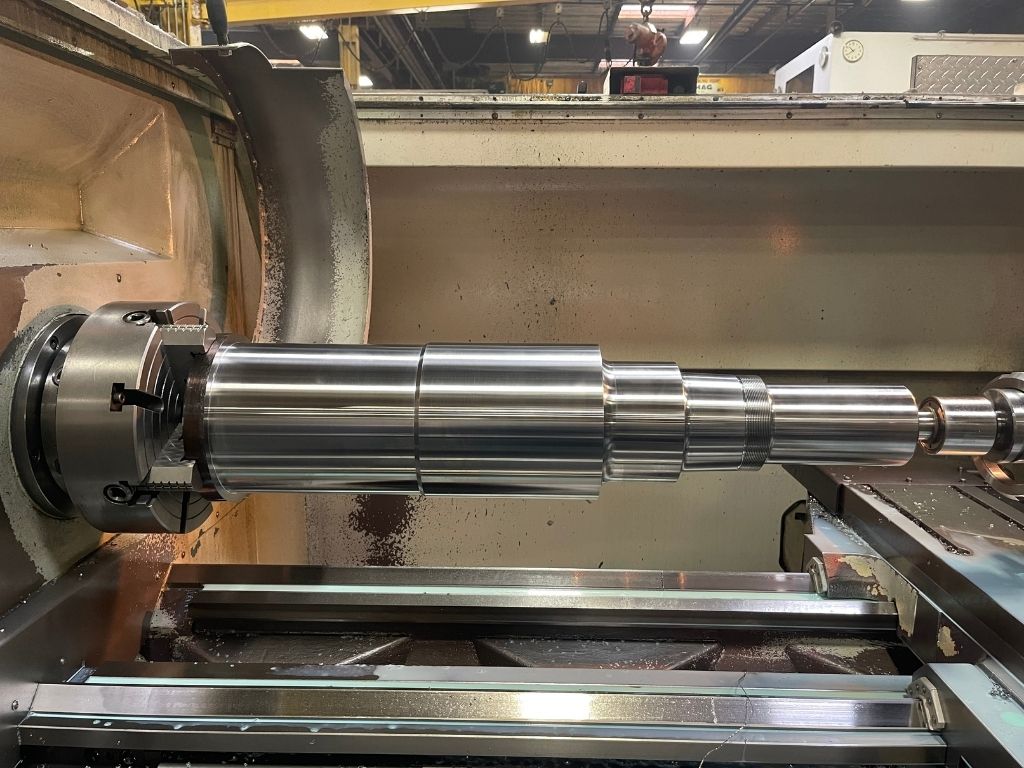

Shafts may become worn down by mechanical, hydraulic, or environmental processes. Whether this degradation is caused by metal-to-metal friction, exposure to corrosive elements, or vibrational forces, our team has the expertise to repair and refurbish industrial shafts, restoring them to OEM specifications, achieving tight tolerances, and optimizing performance to meet operating requirements. Industries that have come to rely on our engineered shaft repair and refurbishment, include wind, hydro, marine, steel and mining, pulp and paper, manufacturing, and large heavy industries.

Comprehensive Shaft Repair

Over the course of time, wear and tear, corrosion, vibration, friction, or other factors can cause damage to a shaft. When a shaft is damaged or non-functional, repairing may prove more viable than a full replacement. Our team can help determine the best option to meet your project specifications and operating requirements.

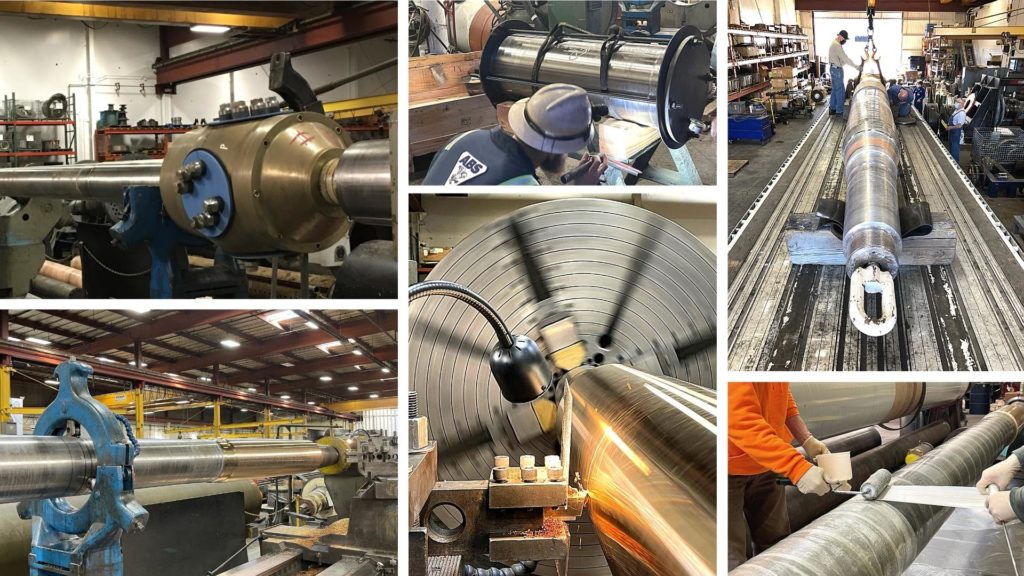

Our comprehensive shaft repair includes the following work scope, which may vary depending on the project, extent and nature of the damage, and other parameters.

- Disassembly and assembly.

- Dimensional inspection of all critical fits and TIR across the shaft.

- Non-destructive testing.

- Root cause failure analysis.

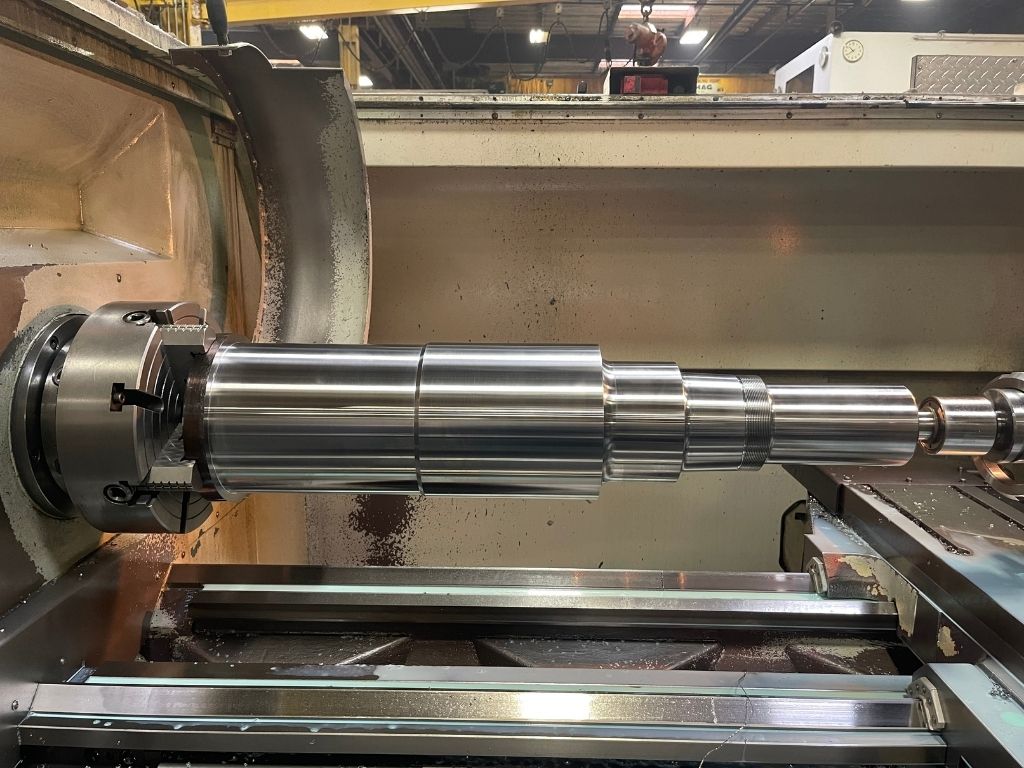

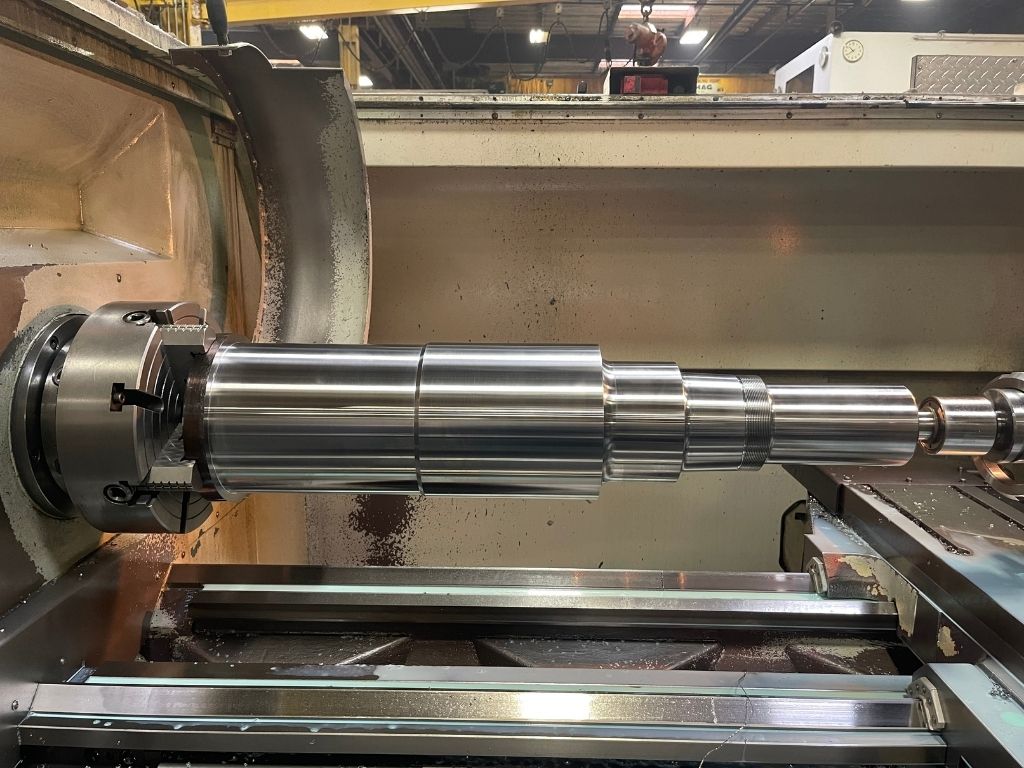

- Precision machining.

- Manufacturing of liners and sealing rings (as applicable).

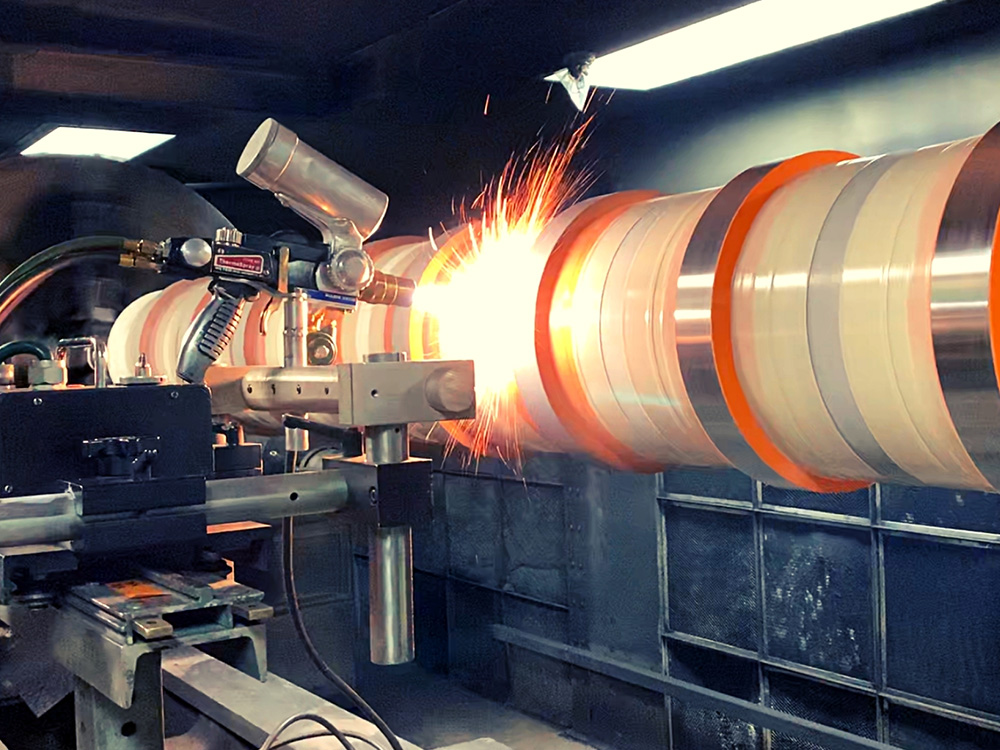

- Thermal spray (as applicable) to restore bearing fits and add protective coating.

- Final dimensional inspection and documentation.

- Third-party testing and approvals (as applicable).

- Technical final report of work performed and inspection results.

- Quality control and prep for shipping.

- Transportation services.

- Project management and engineering support from start to completion.

Emergency Shaft Repairs

For critical shafts that need to be back in operation in the quickest time possible, our team has the flexibility and adaptability to complete shaft repairs within the required turnaround time. An engineer is assigned to the project and works closely with the customer to define the specifications. The method of repair is proposed after thorough non-destructive testing, dimensional inspection, and failure cause analysis. We have in-house equipment, custom tooling, machining expertise, engineering support, transportation services, and supplier connections to meet even the most demanding timelines.

Scheduled Shaft repairs

For the most efficient asset management and quality control, our team can handle scheduled shaft repair with utmost reliability. We provide project management from start to completion, transportation support, comprehensive technical documentation, and engineered repair solutions that take into account all project parameters. Our process starts and ends with an engineering approach to ensure reliability and long-term equipment performance.

Value-added Shaft Repair Services

Shaft Manufacturing

When shaft manufacturing is the more viable option, no matter the complexity or exacting the requirements, Western Machine Works can manufacture custom shafts that meet OEM standards, tight tolerances, and fast turnaround time. Our engineering team can propose design modifications to improve the reliability and durability of the shafts, and reverse engineer the shaft if no OEM prints are available.

Component Manufacturing

In cases of catastrophic damage and equipment failure, liners, seals, rings, and other assembly parts can be manufactured to ensure long-term reliability. Our team has skilled technicians, engineers, equipment, and custom tooling to design, manufacture, or reverse engineer custom parts.

Boring & Milling

Our facility has 4 vertical boring mills and 6 horizontal milling machines. These orbital tools are used for turning and boring large cylindrical objects, like water turbine runners, wind turbine main shafts, plate roller main rolls, rotor shafts, and motor armature shafts.

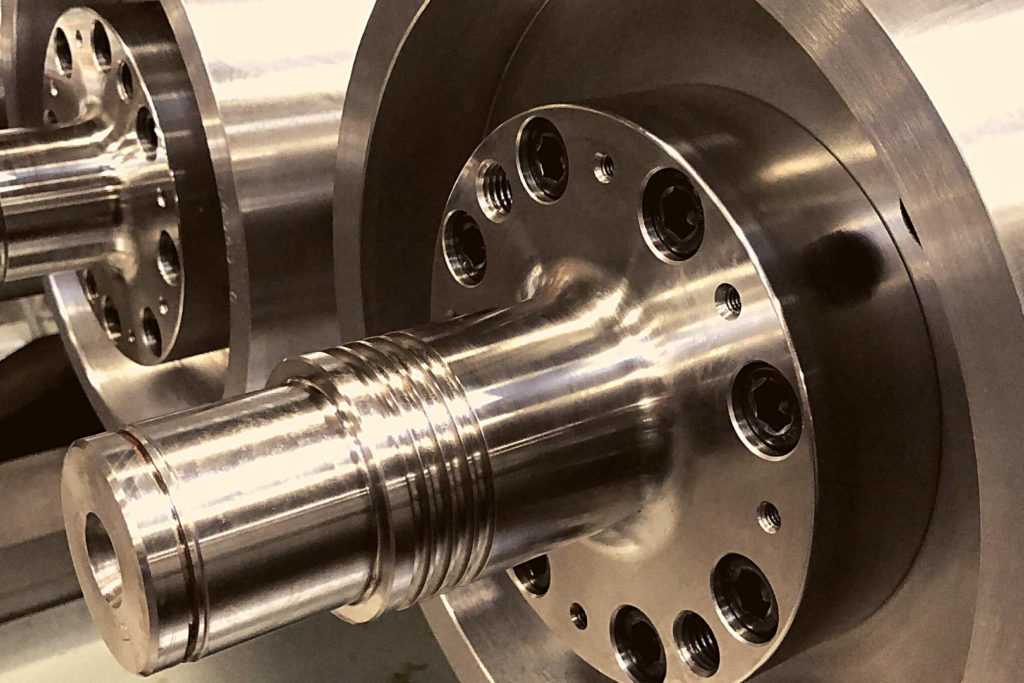

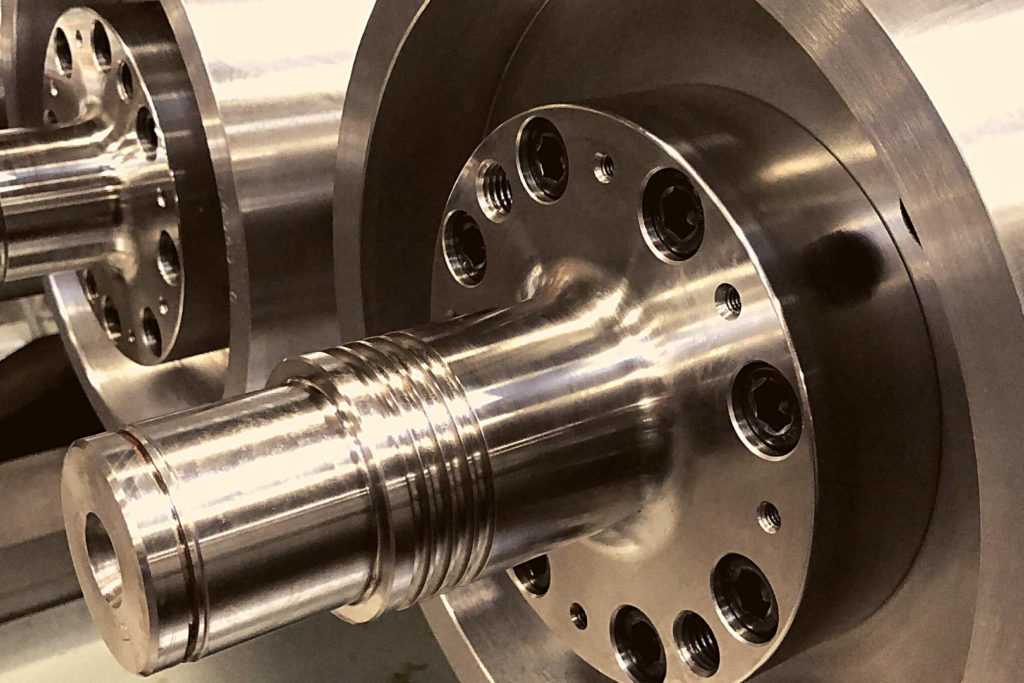

Precision Grinding

Our Farrel Grinder has 44” OD x 312” Face, computer-controlled crowns, 8” superfinisher, and 4” Belt grinder. Tolerance up to .0001” and 4 Ra finish. Our grinding services include OD grinding, honing, superfinishing, and grooving.

Our experienced machinists and technicians are meticulous every step of the grinding process, paying close attention to the machine prep, pre and post-grind measurements, and controlling for deviations.

Dynamic Balancing

Proper balancing is crucially important to any operation that relies on rotating components. Wear and tear, minor damage, and residue can throw the balance off on parts such as rolls, turbines, rotors, and shafts. Western Machine Works is equipped to balance components and parts up to 72” in diameter and 320” in length, using the Schenck Trebel balancer.

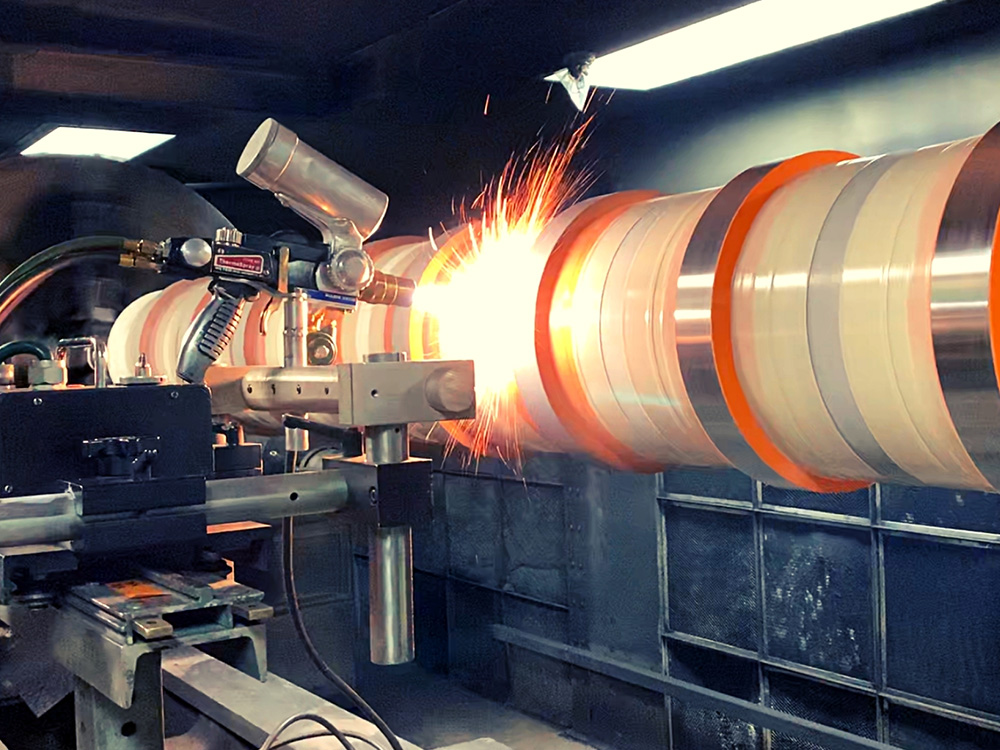

Thermal Spray Coating

Utilizing a twin-wire arc thermal spray process, worn-out equipment and bearing fits are restored to OEM specifications or better. Your critical equipment is repaired, restored, and reconditioned, at less time and cost compared to a full replacement. The thermal spray process utilizes a 420 Stainless Steel coating material that performs well under compression and resists corrosion and erosion. The resulting bond strength approaches 10,000 psi.

Shaft Repair in Critical Industries

Wind, Hydro, Thermal

Western Machine Works has the skilled technicians, project management, custom tooling, and engineering expertise to handle all aspects of industrial shaft repair and refurbishing for wind, hydro, oil & gas, and nuclear industries. We also modify existing shaft designs to meet updated operating parameters. Decades of experience in component manufacturing and reverse engineering to meet OEM specifications.

- Wind Turbine Main Shafts

- Hydro Turbine Runner Shafts

- Gas Turbine Shafts

Marine

Repair and reconditioning of propulsion shafts and components, including propeller hubs, caps, sleeves, and sealing rings. We also provide rudder shaft repair, refurbishing, protective coatings, and line boring of rudder bearings. We can machine the parts to your required dimensions and tolerances with precision and reliability.

- Propulsion Shafts

- Rudder Shafts

- Stern Shafts

- Tail Shafts

- Ship Shafts

Industrial

We repair and refurbish shafts used in industrial equipment for applications in pulp & paper, nonwoven, steel & mining, and manufacturing of electrical components, chemicals, building products, and other heavy industries. With an engineering approach to repairs, shafts can meet the most stringent OEM specifications and operating parameters.

- Rotor Shafts

- Roller Shafts

- Armature Shafts

- Pump Shafts

- Agitator Shafts

Shaft Repair Projects

Roller Shaft

The plate roller shaft broke off of a drive roll with the bearing housing and bearings still installed. The engineering team evaluated the loading parameters and operational stress analysis and developed an interference shaft fit design. A new shaft was manufactured using a 4340 steel material and proved more viable than the original shaft design.

Propulsion Shaft

The ship shaft required extensive repair. Our team performed non-destructive testing, dimensional inspections, precision machining, hydro testing, spark testing, and thermal spraying, and passed all rigorous standards by the American Bureau of Shipping. The propulsion shaft was certified refurbished by ABS after passing all its testings.

forming roll shaft

This forming roll needed to be modified and new shafts manufactured to meet new operating requirements. We provided a comprehensive scope of work including precision machining, manufacturing of new shafts, and engineering services. As a result, the modified roll and new shafts met all of the customer’s specifications.

Here is a partial list of shafts we repair (we can repair other large, complex shafts for heavy industrial equipment):

- Rotor shafts

- Wind turbine shafts

- Hydro turbine shafts

- Gas turbine shafts

- Propulsion shafts

- Rudder shafts

- Pump shafts

- Wheel fan shafts

- Gear shafts

- Agitator shafts

- Process Roll shafts

- Gearbox shafts

Let’s talk about your project.