machine shop Services

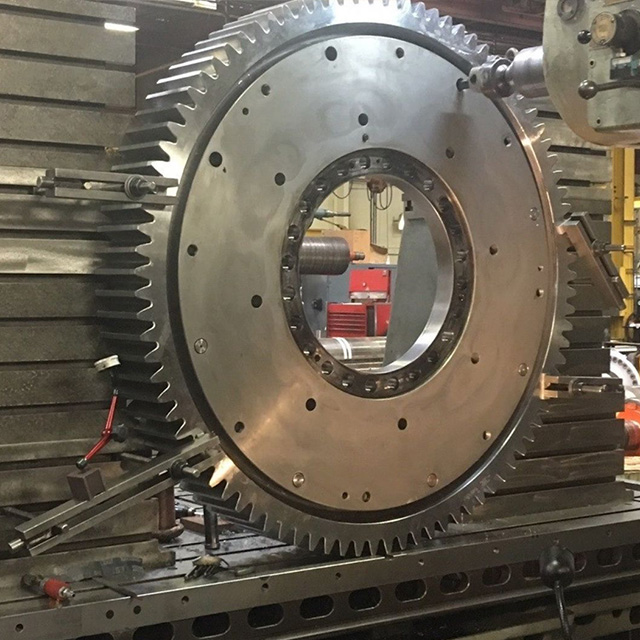

Western Machine Works provides a full range of machine shop services for fast and quality repair, refurbishing, and manufacturing.

Specializing in precision machining, refurbishing, and custom part manufacturing of large industrial equipment for heavy industries since 1985.

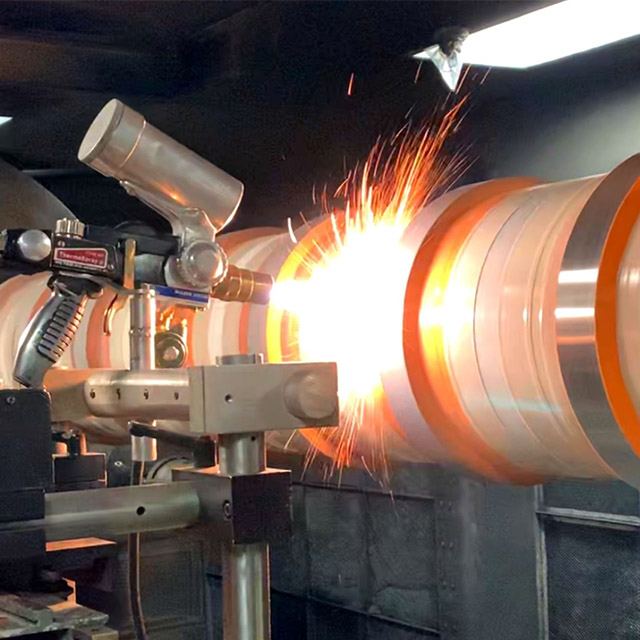

PRECISION ROLL GRINDING

Precision roll grinding and balancing as part of our total roll servicing that deliver on reliability and extended runnability. Every step is engineered for quality results, starting with pre-grind measurements, then pre-machining set-up, dimensional verification and measurements throughout the process, finish grinding to required Ra and post roll grinding reporting.

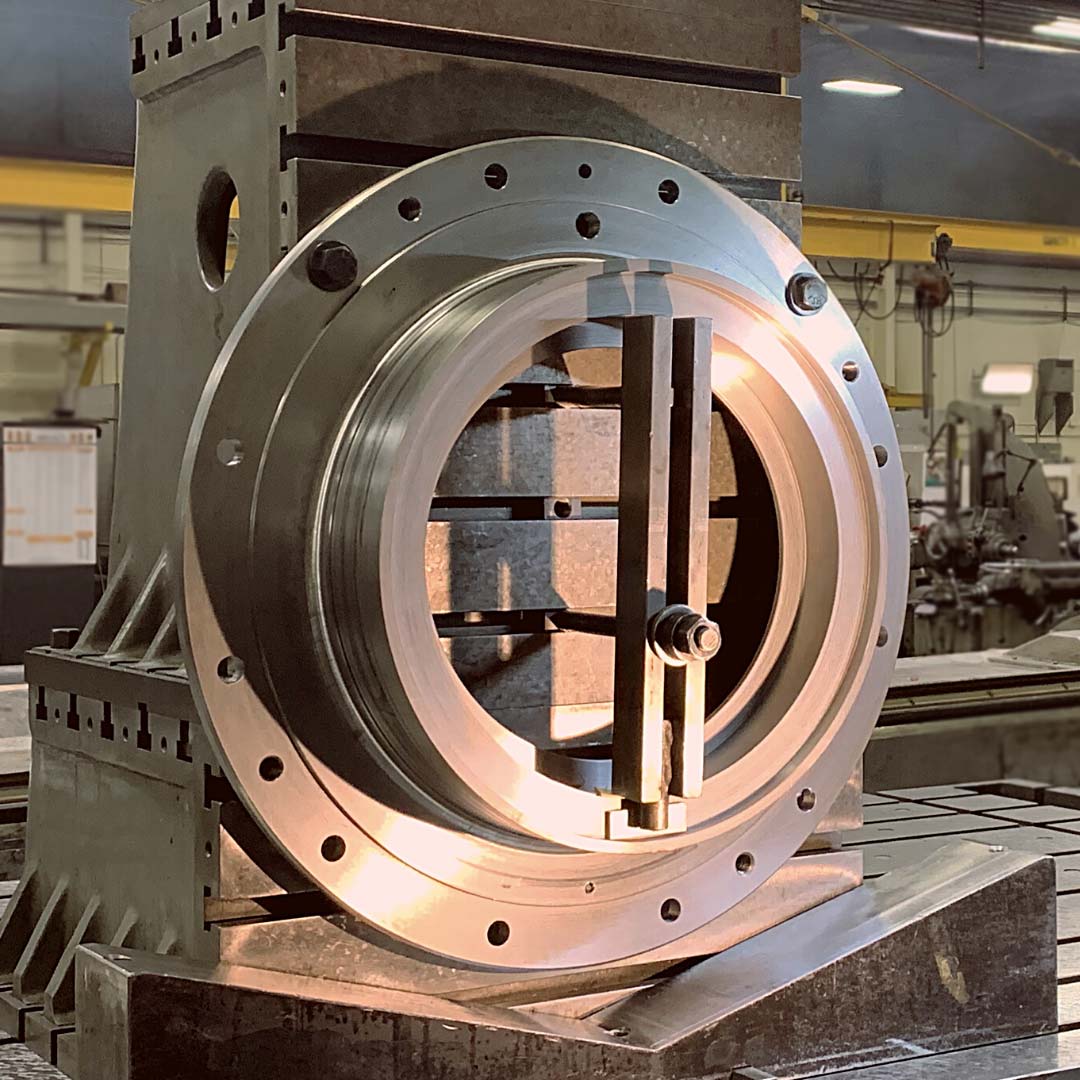

INDUSTRIAL REPAIR

Wear and failure analysis, redesign, and repair of large industrial equipment. Our full-service machine shop specializes in all facets of equipment repair, upgrades, and new manufacture.

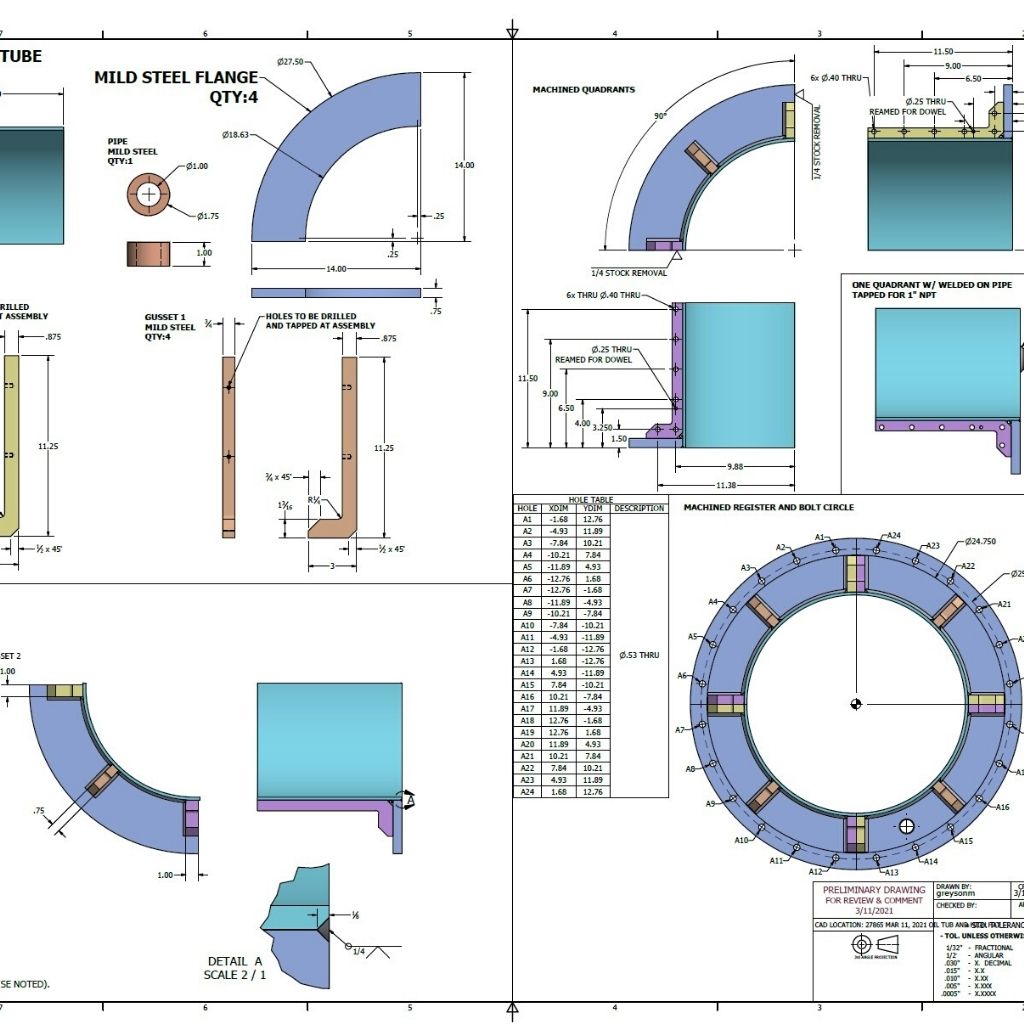

ENGINEERING SERVICES

Mechanical engineering services include failure analysis, reverse engineering, mechanism redesign, industrial equipment upgrades, and project management services.

THERMAL SPRAY SERVICES

Utilizing a twin-wire arc thermal spray process, worn out equipment and bearing fits are restored to OEM specifications or better. Your critical equipment is repaired, restored, and reconditioned, at less time and cost compared to a full replacement.

PRECISION GRINDING

Whether your operation needs OD grinding, honing, superfinishing, or grooving, we provide precision grinding that can meet your most demanding requirements.

NEW ROLL MANUFACTURING

Designing, modifying, and manufacturing new rolls for spares or high-performing roll replacements that meet your operating parameters. With skilled engineers and technicians, we can manufacture new rolls with precision and reliability with or without OEM specifications available.

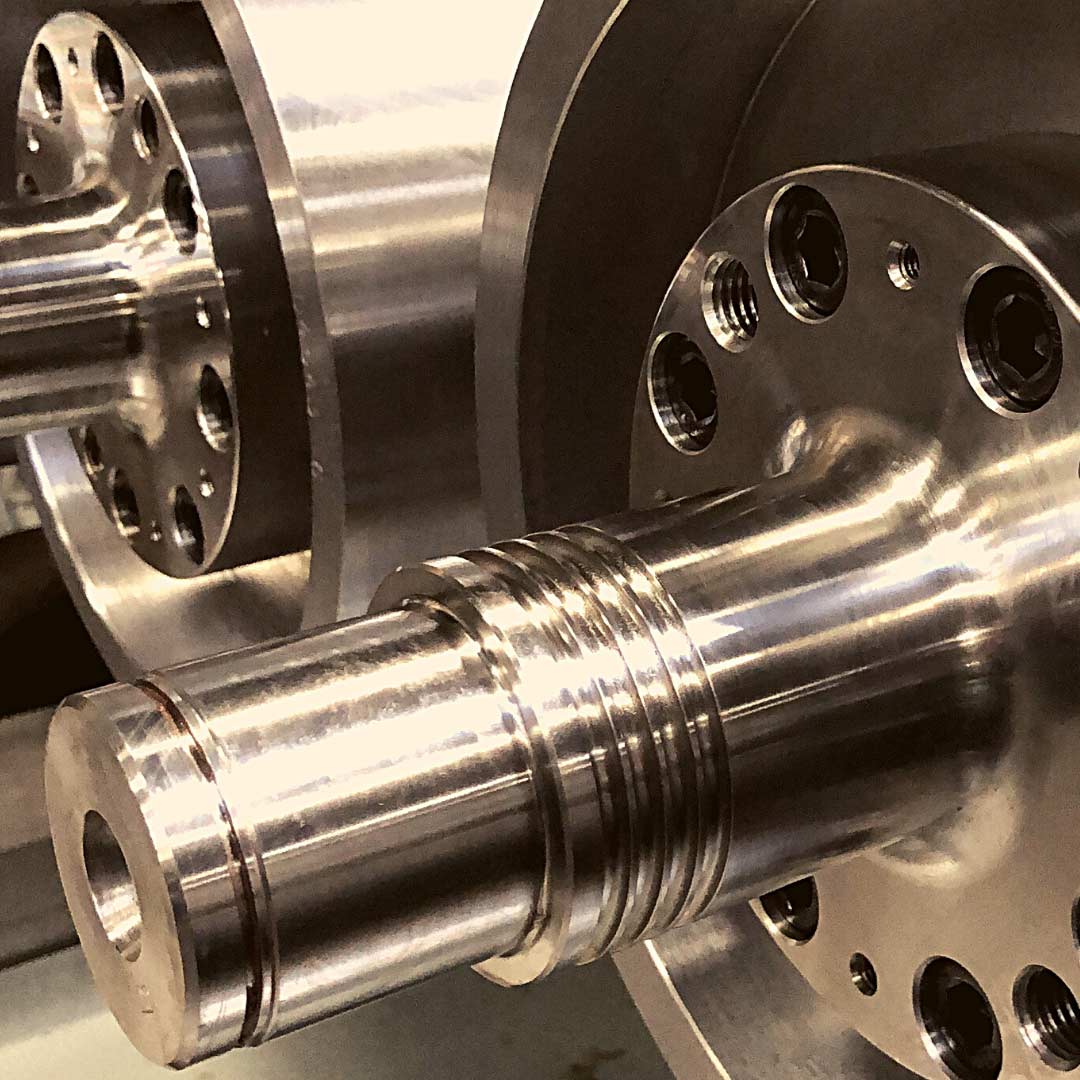

PRECISION MACHINING

Our experienced team of engineers and machinists specialize in fabricating, machining, and manufacturing large industrial equipment with very tight tolerances and exacting parameters.

SHAFT MANUFACTURING

Western Machine Works can manufacture custom shafts that meet OEM standards, tight tolerances, and fast turnaround time. With in-house engineering team, experienced machinists, and transportation services, we can provide cost effective and fast shaft manufacturing that can return your critical shaft back in operation within your project timeline.

Let’s talk about your project.