Wind Turbine Main Shaft Repair & Rebuild for Repower

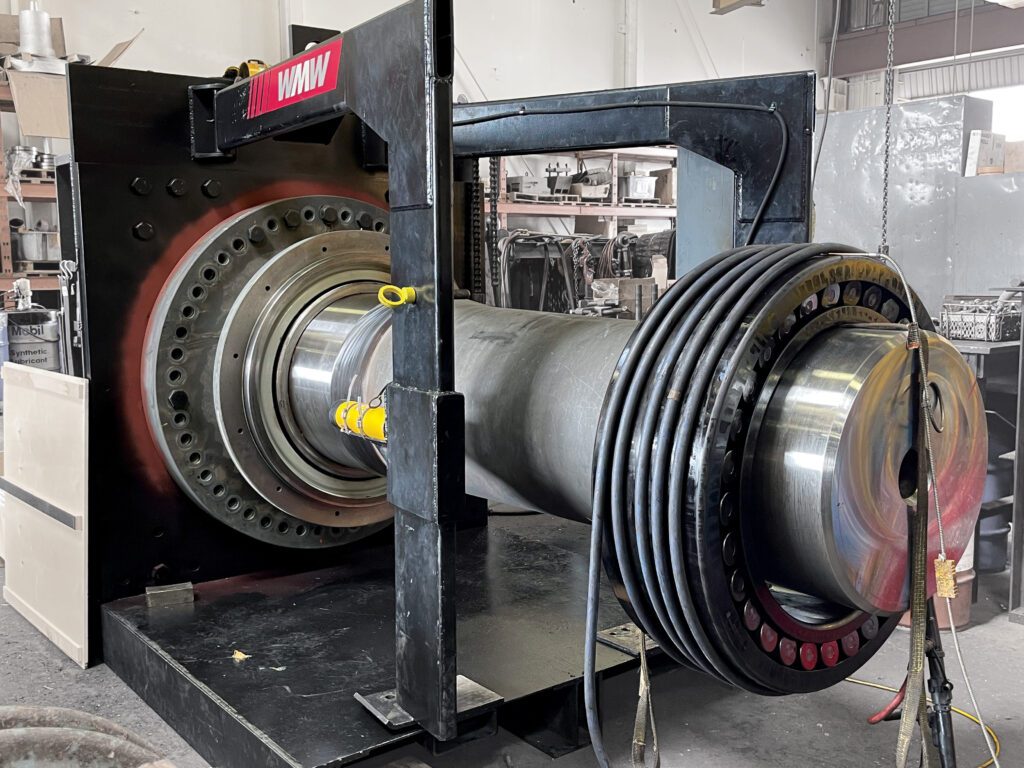

Western Machine Works provides repowering support for wind turbines and wind power plants. We have been an OEM-Certified main shaft repair facility since 2007.

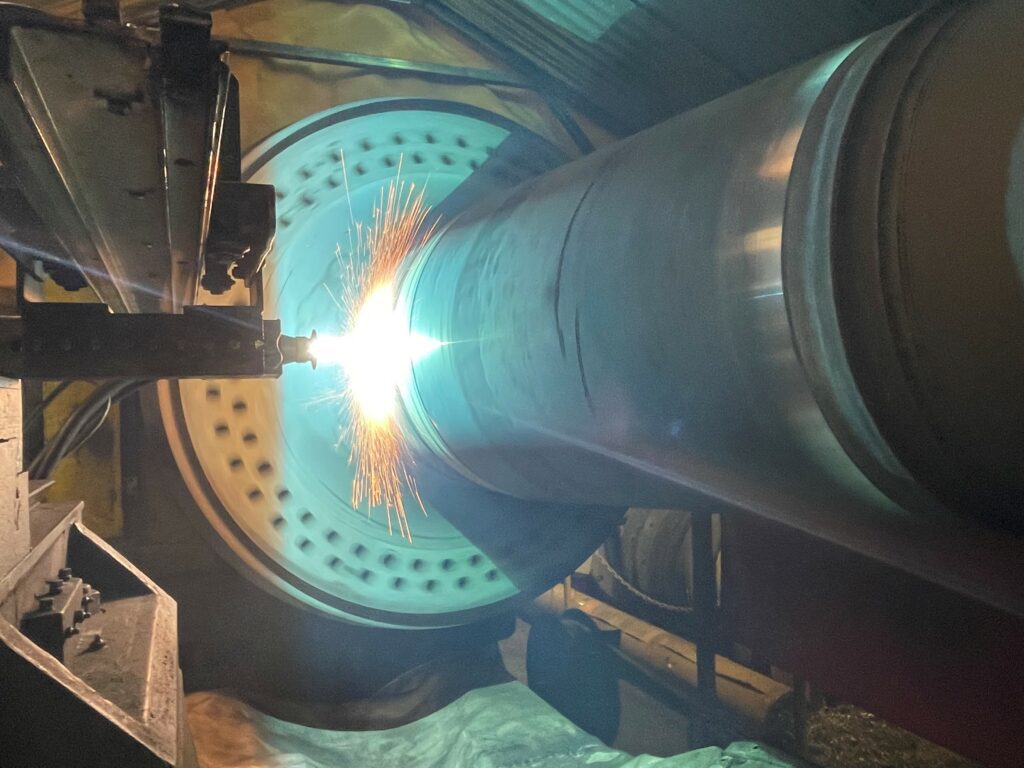

With 400+ main shaft rebuilds and zero warranty issues, WMW is a proven expert in main shaft rebuilds for wind turbines. We use a unique stainless steel thermal spray process that restores main bearing fits and worn-out surfaces to OEM specifications.

Our Main Shaft Repair Capabilities for Wind Repowering:

- Complete main shaft rebuilds, including bearing fit restoration in a week or less. Includes main shaft disassembly and assembly. We are currently supporting Pacific NW repower projects, requiring rebuilds of (2) Siemens 2.3 MW shafts per week.

- Flexible scheduling allows quick response to weather-related issues. We adapt our schedule to keep ahead of your crane schedule.

- Sourcing of main shaft bearings and sealing components at competitive prices.

- Experience working on multiple makes and models of main shafts, with engineering expertise and skilled craftsmanship required to repair any main shaft.

- Custom tooling and fixtures designed specifically for main shaft repair efficiency and safety.

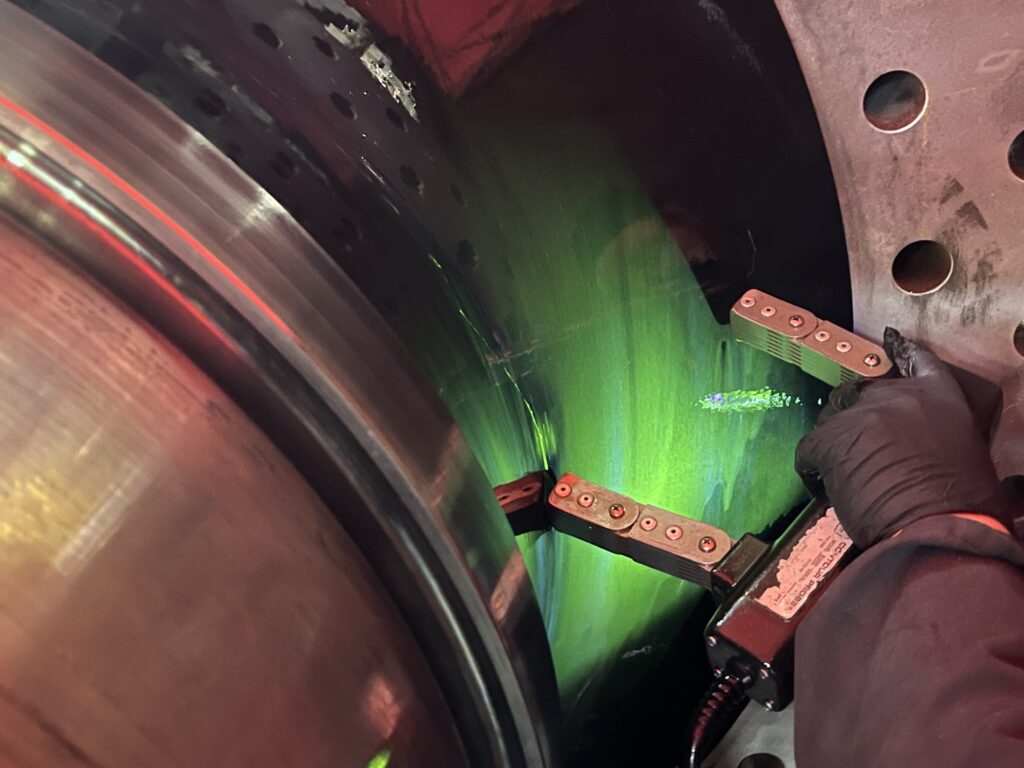

- Bearing inspection and failure analysis.

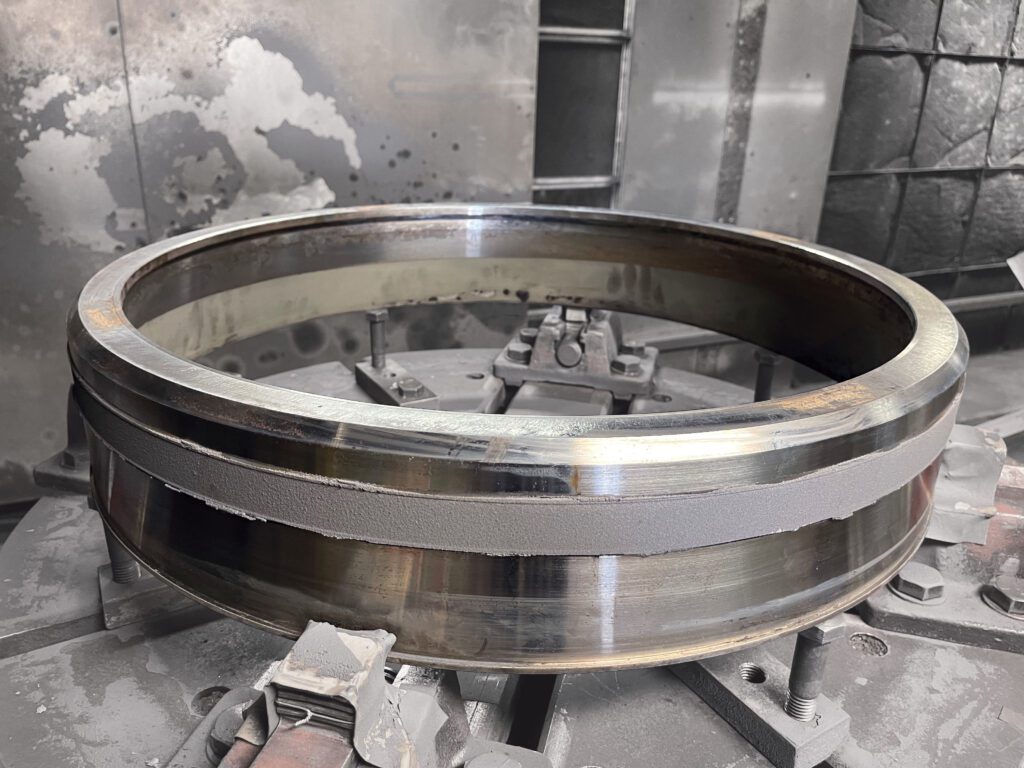

- Bearing fit repair using thermal spray processes, which restores the bearing fit to OEM sizes, improves surface characteristics, and adds resistance to fretting corrosion.

- Accommodate custom undersized bearings. Bearing fit repairs and re-machining to accommodate custom undersized bearings.

- Non-Destructive Testing and dimensional inspection of all components

- Sealing assembly repairs and upgrades, with the capability to manufacture components.

Why Repower with Western Machine Works

We are an OEM-certified main shaft repair facility since 2007, with an experienced team that can rebuild your wind turbine main shaft assembly within 10 days. Our team has the expertise in machining and engineering to meet the technical requirements of multiple wind turbine OEMs, including Vestas, GE, Suzlon, Siemens, Mitsubishi, and other top brands. Our Zero warranty claim record and 100% schedule compliance speak for the quality of our wind repowering support services.

1. Quick Turn Rebuilds

Our main shaft rebuild process is efficient and our scheduling is flexible. We work to keep ahead of your crane schedule.

2. Multi-Brand Expertise

Experienced working on Siemens, Vestas, Mitsubishi, GE, Suzlon, and other brands.

View Wind Turbine Brands & Models List

3. Zero Warranty Issues

Our specialized and OEM-approved repair process using a 420 stainless steel thermal spray process restores main bearing fits and worn out surface to OEM specifications. Tracked performance for all repaired main shafts resulted in 100% quality compliance with zero warranty issues.

Wind Turbine Main Shaft Repair Process

Why Repower?

Over the past few decades, wind power has grown in popularity. At the same time, efficiency and energy production power has increased in newer equipment. Because some of the wind power stations are older, they need to have their equipment upgraded to maximize production. A 2015 study by the Global Wind Energy Council estimated 17% of capacity wind power facilities were more than ten years old. Energy output drops about 1.6% per year on average, so after twenty years, many wind turbines need to be upgraded.

Repowering is a practical solution that also takes warranties into account. Manufacturers’ warranties usually last between eight and 20 years. Wind turbines are usually replaced when they are aging, to avoid costly repairs. Spare parts can also be more difficult to find for older models of wind turbines. Repowering helps replace and upgrade wind facilities in a proactive manner.

Important Questions About Repowering

What is repowering?

Repowering projects are when an aging wind farm is updated. This can involve different components being repaired, refurbished, or replaced, like wind turbines, blades, towers, or other equipment. A repowering project can also involve updating infrastructure, adding more turbines, or improving other parts of the wind farm to improve energy production and efficiency. There are many things to consider when evaluating whether a wind farm should be repowered.

What are the benefits of repowering?

According to EERE (Office of Energy Efficiency and Renewable Energy, wind repowering enables Wind repowering enables owners to retrofit power plants on existing sites with new and/or refurbished technology, including erecting taller, more efficient wind turbines to increase productivity. Repowered projects can often gain further cost-saving advantages, relative to new greenfield (or vacant-lot) developments, by using existing grid connections and infrastructure. Other financial advantages and production efficiency increase, repowering also includes benefits such as geographical expansion and creation of community development through the repurposing of existing land around repowered sources.

What should you consider in repowering?

Wind power components have increased in efficiency over the last decade. If your wind turbines are aging, there are factors to consider when deciding whether to invest in a repowering project.

- Age of wind towers. Wind farms that were built more than 10 years ago, the turbines are probably less efficient than modern wind turbines. Newer, larger turbines can capture more wind energy and generate more power. Doing a professional analysis of your wind turbine efficiency can tell you whether your wind farm is a good candidate for repowering.

- Productivity patterns. Wind turbines tend to lose a small amount of efficiency each year. If you see the power production decreasing over time, you might be able to drastically increase production through a wind repowering project.

- Maintenance costs. If you see consistently higher than normal maintenance costs, due to damaged blades, turbine failure, and repair and maintenance, it may be time to upgrade your wind power equipment. Start by analyzing your wind turbines to see if upgrading through a repowering project will be more cost efficient than repairing.

What is decommissioning?

Decommissioning a wind farm is not merely leaving the equipment not in operation, but deconstructing all the wind farm equipment and returning the land to the original state. Many wind farms are on multiyear agreements with the neighboring communities. Decommissioning is one option for an aging wind farm, though most choose to repower the facility.

In a decommissioning, the materials are disassembled and recycled, with remaining materials going to disposal.

Because building wind farms requires a major investment in infrastructure like roads, community agreements, and local economics, repowering is usually the preferred option. Repowering a wind farm almost always results in an increase in energy production.

What components can be repowered?

Repowering wind farms may involve replacement or refurbishing of mechanical and electrical equipment, including gearboxes, hubs, main shafts, and bearing assembly.

How much does energy production efficiency improve in a repowering project?

According to the Office of Energy Efficiency and Renewable Energy, the average capacity factor, a measure of energy productivity, has increased from 22% in 1998 to 35% in 2021. Wind energy costs have also decreased from 55 cents (inflation adjusted) per kilowatt hour in 1980 to less than 3 cents per kWh in 2021 in the US. Because of lower costs and increased production, upgrading equipment can lead to higher productivity.

Wind Turbine Capabilities

Servicing All Major Wind Turbine Brands

| Siemens |

|---|

| SWT-2.3-93 |

| SWT-2.3-101 |

| SWT-2.3-108 |

| Vestas |

|---|

| V82-1.65 |

| V80-1.8 |

| V80-2.0 |

| V47-0.66 |

| V100-1.8 |

| Mitsubishi |

|---|

| MWT600 |

| MWT62/1.0 |

| MWT95/2.4 |

| GE |

|---|

| GE1.5-77 |

| GE1.7-103 |

| GE2.0-116 |

| GE2.5-100 |

| Other Brands |

|---|

| MM92 |

| S88 |

| G58-0.85 |

| G90-2.0 |

NOTE: This is a partial list of the turbines that we support. Contact us for a free consultation and quote for your specific wind turbine model.

Wind Turbine Services

- Main Shaft and Primary Bearing Disassembly

- Complete Dimensional Inspection of All Main Shaft Components

- Non-Destructive Testing of Main Shafts

- Bearing Inspection and Failure Analysis

- Bearing Seat Grinding to Next Size Bearing

- Bearing Housing Restoration

- Complete Re-assembly of All Main Shaft Components

- Expedited Repair Schedules to Accommodate Crane Schedules

- Custom Lifting and Transportation Fixtures

Let’s talk about your project.