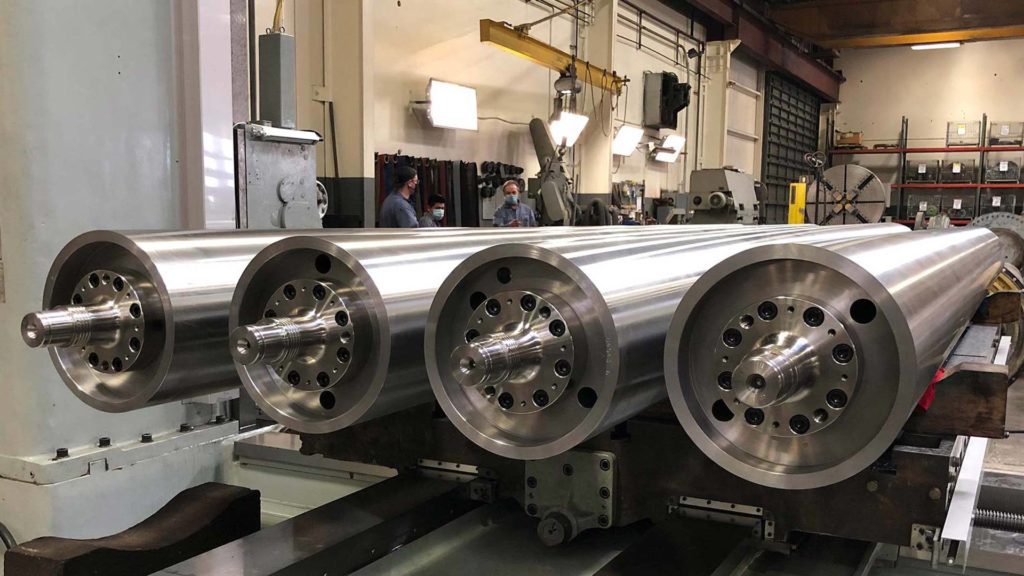

If your roll requires precision grinding, Western Machine Works has skilled technicians and state-of-the-art grinding equipment to meet your needs and specifications. We have been providing precision grinding services for a variety of rolls and cover types since 1985.

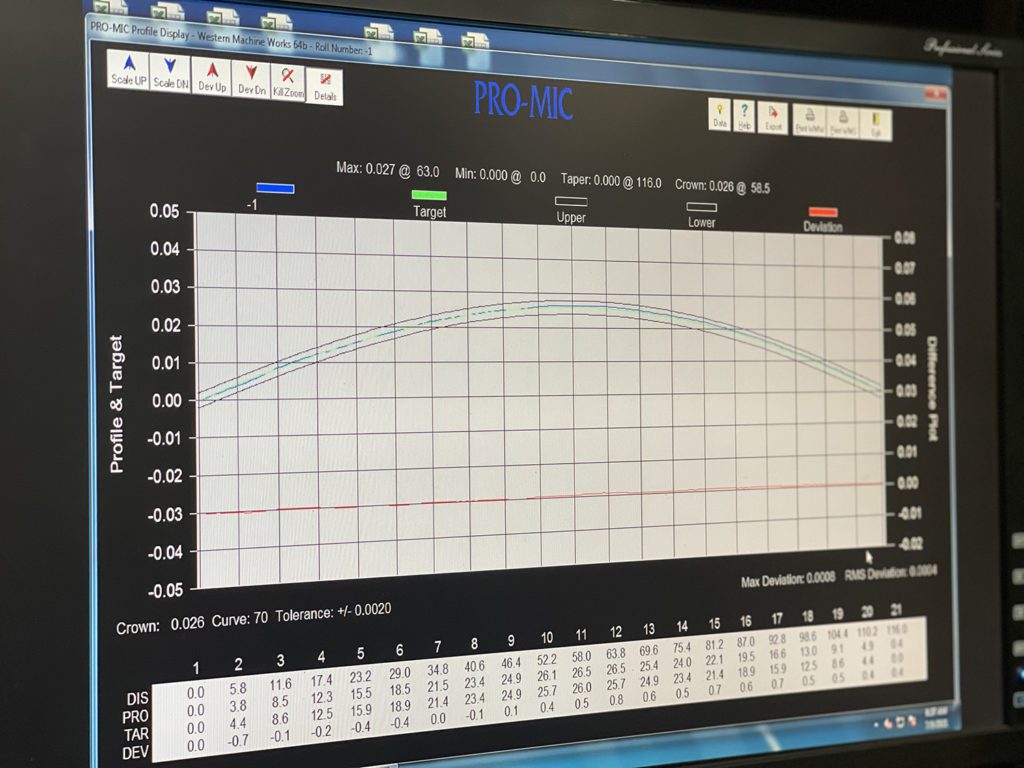

Pre-grind and post-grind profiles are taken using our customized Pro-Mic Roll Measurement System. Pre-grind profiles are analyzed to provide feedback to our customers regarding operational, wear, or loading issues that can be corrected to optimize performance and extend grind cycle frequencies. A Gem Super Finisher is also utilized to assure consistent surface finish requirements.

ISO 21940 G Grade specifications are used for balancing rolls on our SCHENK balancing machine. Most industrial rolls are balanced at G1.0 specifications with some sensitive rolls being balanced to G.1 specifications. Western Machine Works also offers a unique service of checking baseline vibration analysis of bearings to minimize the chance of a defective bearing being placed in service.

What You Need To Know About Precision Grinding

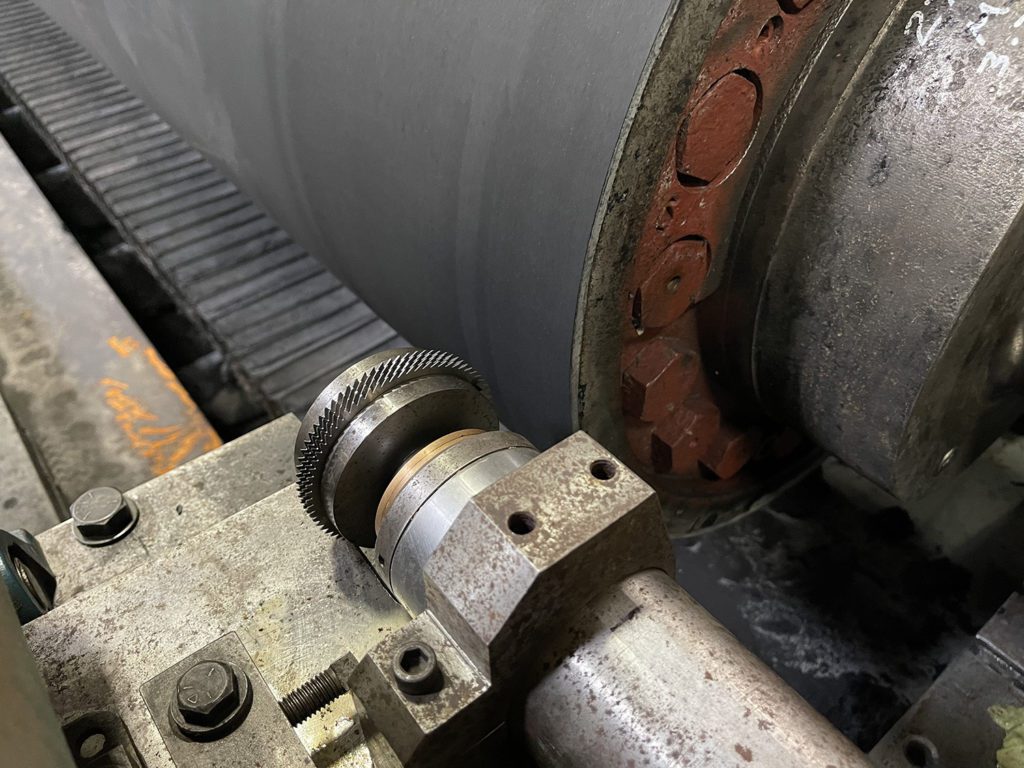

Precision roll grinding is a surface finishing process used in manufacturing and fabrication that focuses on extreme accuracy and tolerances, down to thousandths of an inch or less. Precision roll grinders usually attach a workpiece to a rotating axis, with a grinding wheel rotating on the outside diameter of the object, removing material to a specified tolerance. New or refinished rolls may undergo different finishing processes after precision roll grinding, including coating or superfinishing.

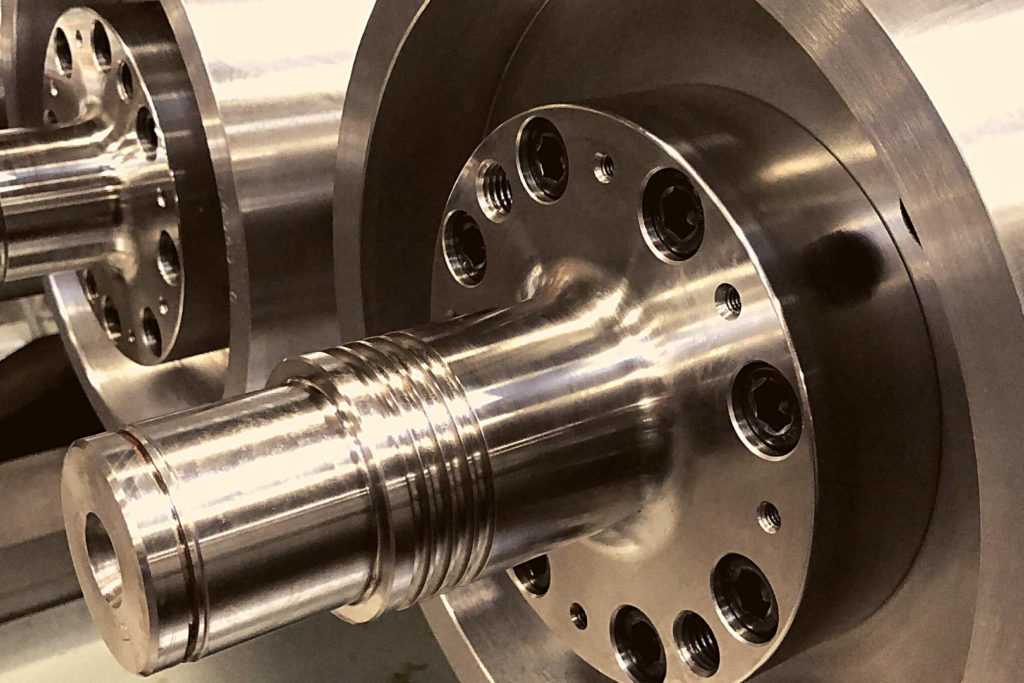

Rolls that have been plated with metallic alloys must still undergo precision roll grinding to prepare the substrate for a custom finishing process or be polished to a superfinished mirror quality.

Components both large and small can undergo precision roll grinding. Some of the industries that may require precision roll grinding include paper and pulp, textiles, aerospace, medical and pharmaceutical, scientific instruments, manufacturing, and energy.

Our Precision Grinding Capabilities

Meeting your tight tolerance specifications: +-.0001 tight tolerance and 4 Ra finish. For your specific type of roll and cover, there is a standard tolerance recommended. You may refer to the chart below for the precision grinding recommendations.

Precision Roll Grinding Tolerances Guide

| Roll Type | Shape | Taper | TIR | Crown | Sta. to Sta. | Surface Finish |

| King Calender Rolls | .0004″ | .0004″ | .0005″ | +.0004″ / -.0004″ | .0003″ | 6-8 Ra |

| Queen Calender Rolls | .0004″ | .0004″ | .0005″ | +.0004″ / -.0004″ | .0003″ | 6-8 Ra |

| Intermediate Calender Rolls | .0004″ | .0004″ | .0005″ | +.0004″ / -.0000″ | .0003″ | 6-8 Ra |

| Controlled Crown Rolls – Chilled Iron Shell | .0004″ | .0004″ | .0005″ | +.0003″ / -.0000″ | .0003″ | 6-8 Ra |

| Gloss Calender Rolls | .0005″ | .0004″ | .0003″ | +.0005″ / -.0005″ | .0003″ | 6-8 Ra |

| Breast Rolls (Suction and Open) | .001″ | .002″ | .001″ | 5% (+/-) | .001″ | 32 Ra |

| Breast Rolls (Solid) | .001″ | .002″ | .002″ | 5% (+/-) | .001″ | 32 Ra |

| Suction Couch Rolls – No Cover | .002″ | .002″ | .002″ | 5% (+/-) | .001″ | 32 Ra |

| Wire Rolls & Wire Turning Rolls – No Cover | .002″ | .002″ | .002″ | 5% (+/-) | .001″ | 32 Ra |

| Pickup Rolls – Suction & Plain – No Cover | .002″ | .002″ | .003″ | 5% (+/-) | .001″ | 32 Ra |

| Suction Felt Rolls – No Cover | .002″ | .002″ | .002″ | 5% (+/-) | .001″ | 63 Ra |

| Felt and Paper Carrying Rolls – No Cover | .003″ | .005″ | .003″ | +.005″ / -.000″ | .002″ | 63 Ra |

| Granite Rolls | .002″ | .002″ | .002″ | 5% (+/-) | .001″ | 32 Ra |

| Reel Spools, Reel Drums, Can Dryers | .002″ | .004″ | .003″ | +.004″ / -.000″ | .001″ | 63 Ra |

| Rubber and Polyurethane Covers: | .002″ | .002″ | .002″ | .002″ | .001″ | 180 Grit |

| Total Crown .000″ – .010″ | +.0008″ / -.0008″ | |||||

| Total Crown .011″ – .025″ | +.0015″ / -.0015″ | |||||

| Total Crown .026″ – .050″ | +.0025″ / -.0025″ | |||||

| Total Crown .051″ – .100″ | +.0030″ / -.0030″ | |||||

| Total Crown >.100″ | +.0040″ / -.0040″ | |||||

| Speciality Cover Finishes: | ||||||

| Brass or Stainless | 16 Ra | |||||

| Size Press Rolls | 320 Grit | |||||

| Coater Backing Rolls | 320 Grit | |||||

| Lumpbreaker Rolls | 50 Grit |

Our Precision Grinding Equipment

Farrel: 44” OD x 312” Face, computer-controlled crowns, 8” superfinisher, 4” Belt grinder.

Tolerance up to .0001” and 4 Ra finish.

Lobdell

Cincinnati

Pro Mic software

Measurement tools: P&J Gauge and Mitutoyo Surface Roughness Gauge.

We Go Above and Beyond with our Precision Roll Grinding

Total Roll Servicing Program

Western Machine Works provides a comprehensive roll maintenance program for all types of rolls, regardless of the original equipment manufacturer. The Total Roll Servicing Program includes:

- Disassembly & Inspection for a thorough evaluation, involving multi-point inspection of all rolls, rigid documentation of dimensional data, and non-destructive testing of critical components (including suction roll shells).

- Engineering to evaluate all inspection data against OEM specifications and identify indications of problems associated with the roll’s performance.

- Repairs of virtually any component on your roll and approached from an engineering standpoint to assure reliability.

- Grinding of all roll types and covers made of materials such as polyurethane, rubber, composites, and chilled iron.

- Balancing of roll equipment that meets your operating parameters.

- Final Preparation wherein all rolls are carefully protected and prepared for transportation and storage. Roll tags identifying lubrication type, grinding specifications, and other vital information are attached to the roll.

- Documentation for all completed jobs with a final report with a complete scope of work performed and all pertinent inspection sheets.

- Transportation Services ensure that your rolls are transported in a safe and economical manner. Our drivers are trained to transport rolls using specialized equipment.

Turnkey Project Management

A single-source solution that requires minimal input or supervision by your staff. We minimize your time involvement by handling the entire project from removal, to repair, to installation.

Let us know your objectives, and we’ll handle the rest—everything from conceptual drawings to collecting and verifying dimensional measurements to final manufacturing. We’ll even provide technical assistance at the time of installation.

Precision Roll Grinding

Multiple roll grinders and grinding techniques allow us to match your application and restore your rolls to OEM specifications or better. Our engineering staff will discuss your expectations with you and economically match the requirements to the best technique. Most importantly, our grinding technicians are experienced and meticulous in detail.

Roll Balancing

As machine speeds increase and original design parameters are exceeded, roll balancing becomes increasingly critical. Western Machine Works can assist in selecting the most cost effective balancing specifications to meet your operating needs.

Thermal Spray Coating

Using the twin wire arc thermal spray process, bearing fits are restored to OEM specifications and finished with wear-resistant coating for long-term asset protection. Prior to metallizing, the bearing fit is machined to the proper pre-buildup size (typically .020″ per side), grit blasted to clean and create a profile, and the adjoining areas carefully masked to avoid overspray. The bearing fit is then finished to the original equipment manufacturer’s parameters.

New Roll Manufacturing

Western Machine Works can create a new roll for your production facility to replace a damaged roll, or to proactively create spare rolls, so your facility does not suffer down time due to a lack of replacement rolls. We can create new rolls from existing rolls, or from your specifications.

Roll Refurbishing

Rolls in your facility may become worn or uneven due to wear and tear or human error. When the finish is uneven, it can affect productivity and efficacy. Refinishing or refurbishing an existing roll is often most cost-effective than replacing or fabricating a new roll. We can refinish your rolls to original OEM specs.

Rolls We Precision Grind

We have the equipment, skilled technicians, and custom tooling to provide precision grinding for a variety of rolls including, servicing coater rolls, wire rolls, felt rolls, breast rolls, reel spools, crown rolls, and suction rolls.

Precision Roll Grinding Projects

Helpful Terms and Tips for your Precision Grinding

Calender Rolls

Calender rolls are used in various industries where a material is passed through heavy rolls that are heated to produce an effect, enhance a finish, or create a product. In paper production, calendering makes paper smooth and glossy. Textile mills use calender rolls to create a smooth texture, or create a visual effect (moire, cambric, sateen). Vinyl film is sometimes produced using calender rolls. We can create, balance, and maintain calender rolls in your facility.

Coated Rolls

Used in industries like printing, paper, packaging, and pharmaceutical, coated rolls must have tight tolerances. Coated rolls may have different coatings such as rubber, enamel, polymer, ceramic, slot die, or elastomeric coverings. These rolls must be properly engineered, manufactured, and coated to specific tolerances.

Precision Roll Grinding vs Cylindrical Grinding

These two have some similarities, but also some distinct differences. Roll grinders turn an object on a center axis and an outside grinding wheel removes material from the workpiece. Precision roll grinders were created to handle certain processes and can handle larger, heavier, longer objects than cylindrical grinders. Roll grinding machines are generally much larger and heavier than cylindrical grinding machines.

Cylindrical grinders can include centered and centerless grinding machines. This type of grinding can handle different shapes, like spheres, cylinders, or tapered objects. Cylindrical grinders can also have multiple grinding wheels.

In both precision roll grinding and cylindrical grinding, both the workpiece and grinding wheel are continually rotating opposite each other.

Precision Roll Grinding Parameters and Suggestions

Many facts require consideration if quality grinding is to be achieved to satisfy standards necessary to paper machines today. These include:

- Grinder condition and equipment available

- Roll mounting equipment and condition

- Roll alignment

- Grinding wheel balancing and storage

- Grinding wheel dressing and diamond selection

- Grinding wheel selection and application

- Wheel, workpiece and traverse speeds

- Wheel infeed rates

- Coolant selection and condition

- Grinding the roll

- General information metal rolls

- Belt grinding equipment and condition

- Contact wheel

- Idler puller and belt tension

- Belt and roll speed

- Coolants metal rolls

- Coated abrasive belts metal rolls

- Rubber roll grinding

- Belt and roll speed rubber covered rolls

- General information rubber covered rolls

These items may be considered singly but never separately as each has considerable influence and effect on the others.

Types of Rolls We Refurbish, Design, and Manufacture

- Calender Rolls

- Suction Rolls

- Press Rolls

- Breaker Stack Rolls

- Size Press Rolls

- Coater Rolls

- Wire Rolls

- Felt Rolls

- Breast Rolls

- Reel Spools

- Reel Drums

- Couch Rolls

Let’s talk about your project.