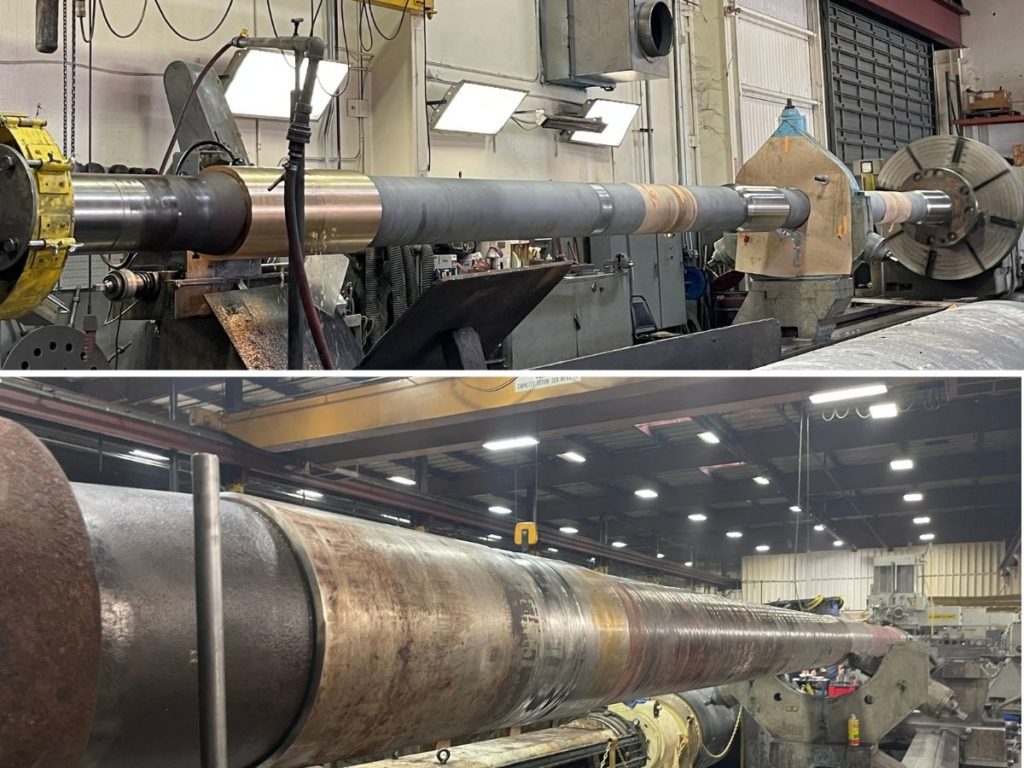

This propulsion shaft for a large towing vessel needed a comprehensive repair solution. All three liners needed to be replaced and required more than just machining. Our team provided engineering support which proved critical in determining the scope of work and defining critical specifications. There were several challenges to the project, but the engineering-focused repair allowed our team to meet all stringent specifications and testing approvals, including a hydrostatic test and spark test within the drydock schedule.

Project:

- Parts: Propulsion Shaft with 3 liners

- Dimensions: 486″ OAL (Shaft); 17,288 lbs; AFT sleeve (39″ length); Mid sleeve (33″ length); FWD sleeve (30″ length)

- Customer: Global ship owner and operator, and maritime logistics provider

Challenges:

- Critical timeline. Shaft repair needed to be completed within the drydock schedule.

- Required very tight tolerances and stringent machining, installation, and testing specifications.

Engineered Solutions:

- Dimensionally inspect all critical fits and check TIR across the shaft and liner locations. Record initial and final results.

- Non-destructive testing of the shaft.

- Machine ID of the three liners for interference fit to the shaft per print and rough turn the OD.

- Hydrostatically test the liners with the customer and ABS witnessing the result.

- Heat the liners with specialized induction heating equipment to assure uniform expansion.

- Install the liners on the shaft per print locations.

- Finish machine the OD of the liners to tight tolerances since the bearings were pre-machined to final sizes.

- Install the fiberglass protective coating between liners.

- Final spark testing of the fiberglass.

Results:

- New liners passed all dimensional inspections and hydro testing, and the new fiberglass passed spark testing.

- All critical fits and TIR specifications were met.

- Completed all machining and repairs within 12 days and delivered the shaft with the new liners on schedule.