Flame spray coating is a thermal spray technique that applies a protective coating to a surface by melting powders or ceramic rods using an oxy- acetylene flame. Flame spray refers to the entire range of systems that use an oxy-fuel flame to atomize the coating material and a pressurized inert gas to propel the droplets to the target surface. Western Machine Works uses the powder flame spray type of thermal spray process. The flame spray greatly enhances the adhesion of the spray coating to the substrate, making it impervious to gases and liquids.

Flame spray coatings create a strong protective coating against corrosion and environmental conditions in a wide variety of applications, including shaft sleeves, rolls, bearing seats, and extruder rotors.

Generally, flame spray coatings are fused to a substrate after application to improve bonding and coating density. Compared to twin-wire arc or HVOF, flame spray coating processes use lower temperatures and propulsion velocities.

The Flame Spray Process

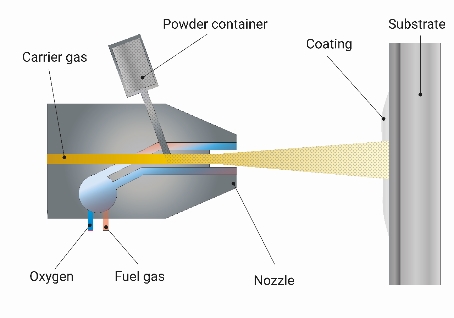

In flame spraying, a gaseous fuel source and oxygen are combined to melt the coating compound feed stock. Usually, the coating material takes the form of a fine powder, wire, or rod that is melted at about 4600-4800 °F. The molten particles are propelled to the substrate surface using compressed air at about 80 feet per second.

For wire fed systems, a metallic alloy wire is fed towards a high-temperature flame created from oxygen and either acetylene or propane. Compressed air propels the atomized metallic particulate towards the target surface.

Powder flame spray systems use a hopper or external feed unit to feed the coating material. This is the metallic coating in powder form. The process is essentially the same as the wire flame spray method in every other way.

Benefits of Flame Spraying

Flame spray coatings offer several benefits.

- Resistant to corrosion, wear, heat and oxidation

- Subsrtate does not warp or distort

- Electrical resistivity and conductivity

Applications for Flame Spraying

Flame spraying is a cost-effective thermal spray technique that can be used for metallizing, strengthening an existing coating, or as a standalone process. Generally, flame spray coatings are applied manually.

Here are common use cases:

- Corrosion protection for components

- Refurbishing of shafts

- Bearings

- Journals

- Rolls

- Wind Turbines

Materials that are Commonly Flame Sprayed

- Stainless steel

- Bronze

- Nickel-based alloys

- Low-carbon Steel

- Aluminum

- Zinc

- Molybdenum

- Carbides

- Ceramics

Let’s talk about your project.