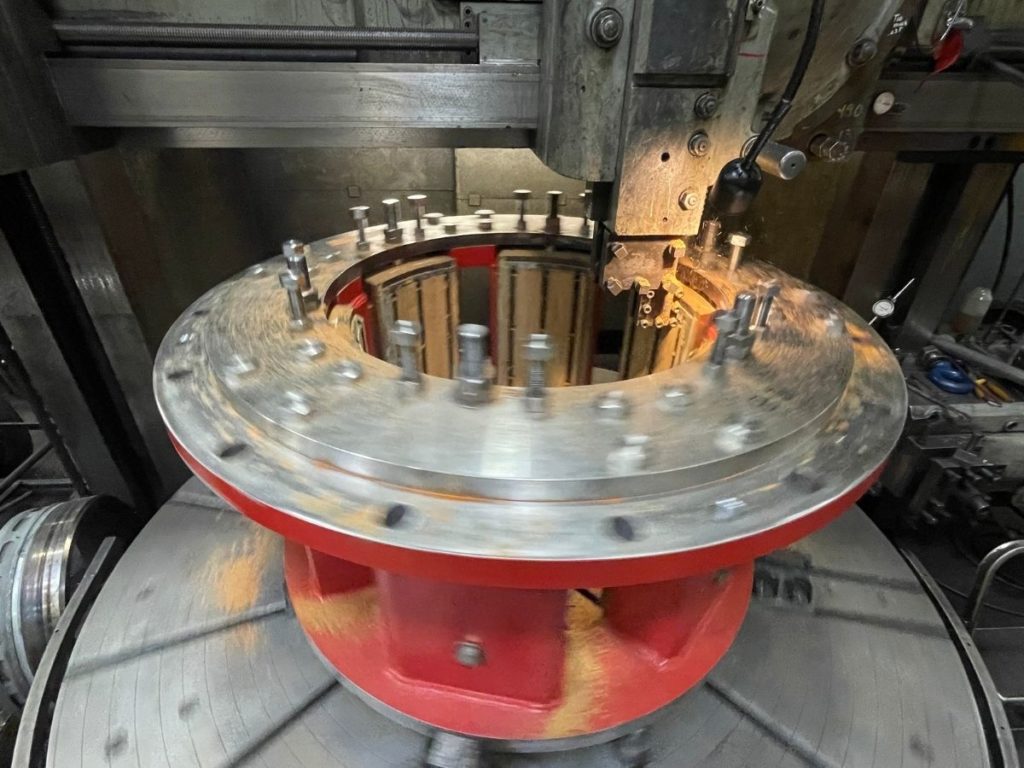

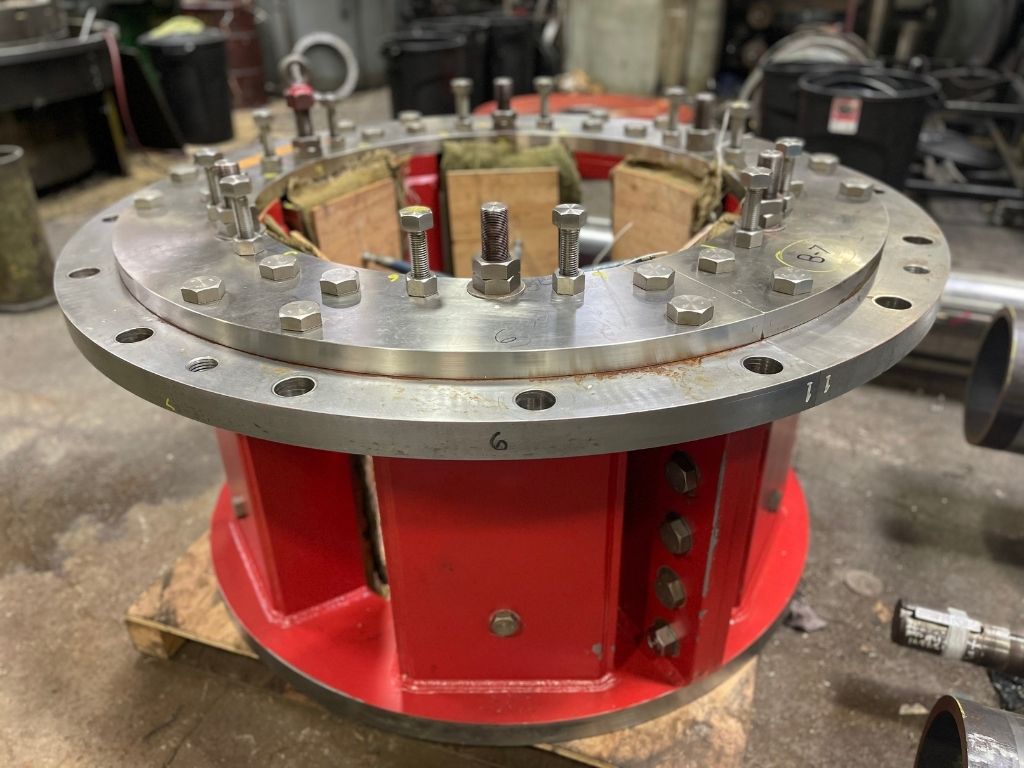

A public utility company in WA needed machining of 2 turbine guide bearings made of lignum vitae wood. The material provided both advantages and challenges. Durable and self-lubricating, the material did require specific handling and protection. Throughout the machining process, Western Machine Works maintained the surface integrity of the lignum vitae wooden staves while achieving the required ID, TIR, and RA finish.

Project:

- Part: Turbine Guide Bearings

- Details: Lignum Vitae material

- Customer: Public utility in WA

Challenge:

- Precise machining of ID, counterbore, ridge, and water grooves.

- Lignum vitae surface is critical and involved exacting material handling requirements.

- Fast turnaround required.

Engineered Solutions:

- Machined off one-half inch per side of material on existing bearing staves.

- Wooden bearing surface machined to customer specifications of less than .003″ diameter deviation and concentricity of .002″ or less.

- Designed and manufactured custom tooling to economically re-machine the water grooves in the wooden bearing staves.

- Turbine guide bearings were coated and protected during shipping via WMW supplied heated transportation.

Result:

- Achieved the required ID, TIRs, and RA finish.

- Maintained Lignum Vitae surface integrity.

- Reinstalled all wooden staves to the guide bearings with the required dimensions.

- Completed withing the customer’s production schedule.